Starting claw plate of impact-resisting air-cooled diesel engine

A technology of starting claws and diesel engines, which is applied to the starting of engines, machines/engines, and starting devices with manual cranks. It can solve problems such as the easy damage of starting claws, and achieve improved impact resistance, cost savings, and long service life. increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

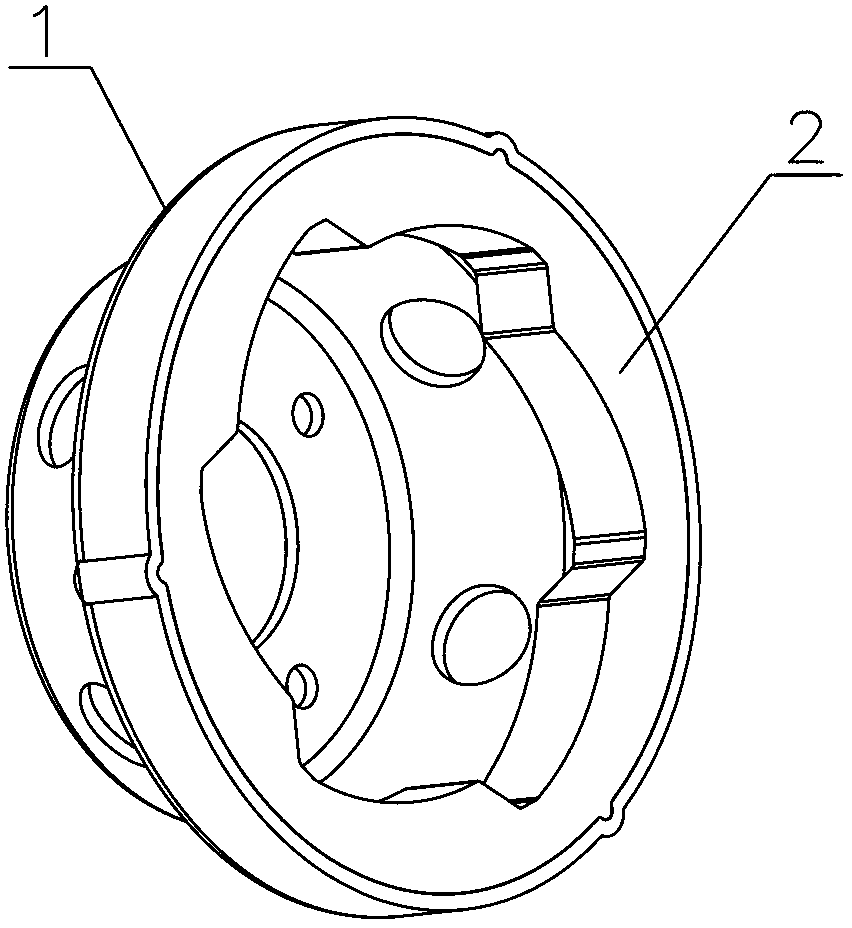

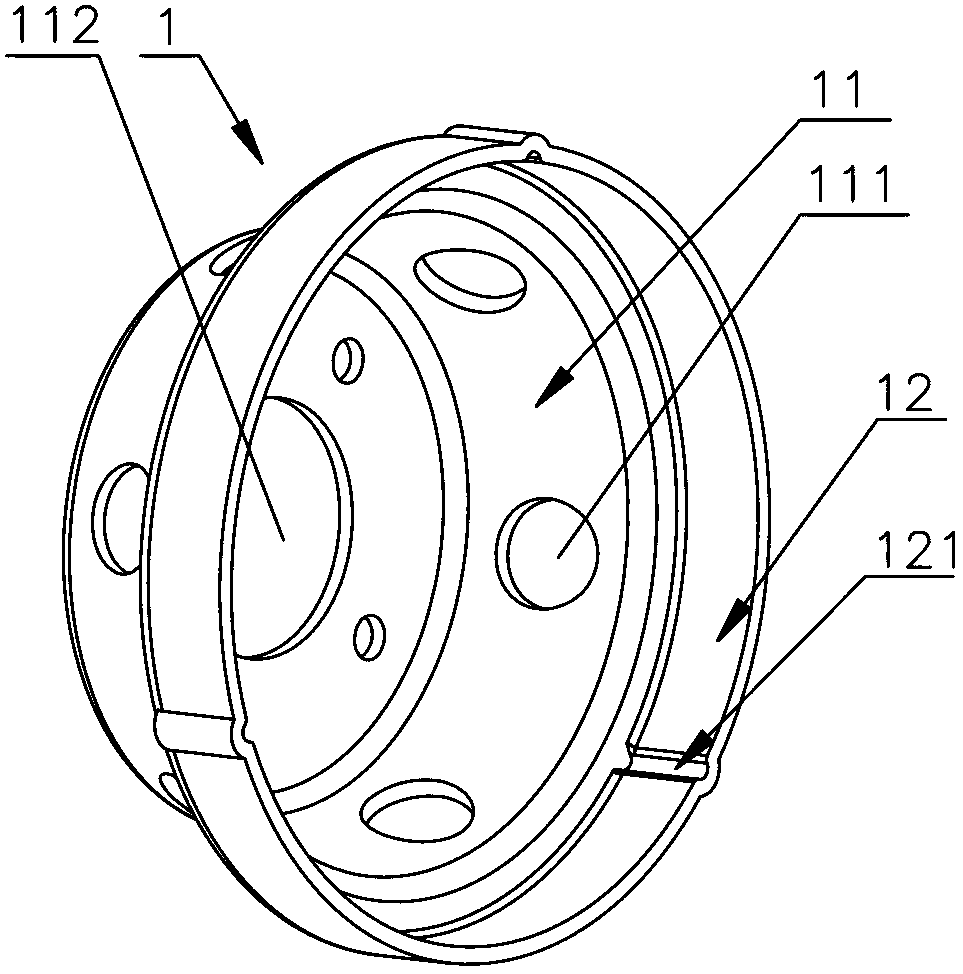

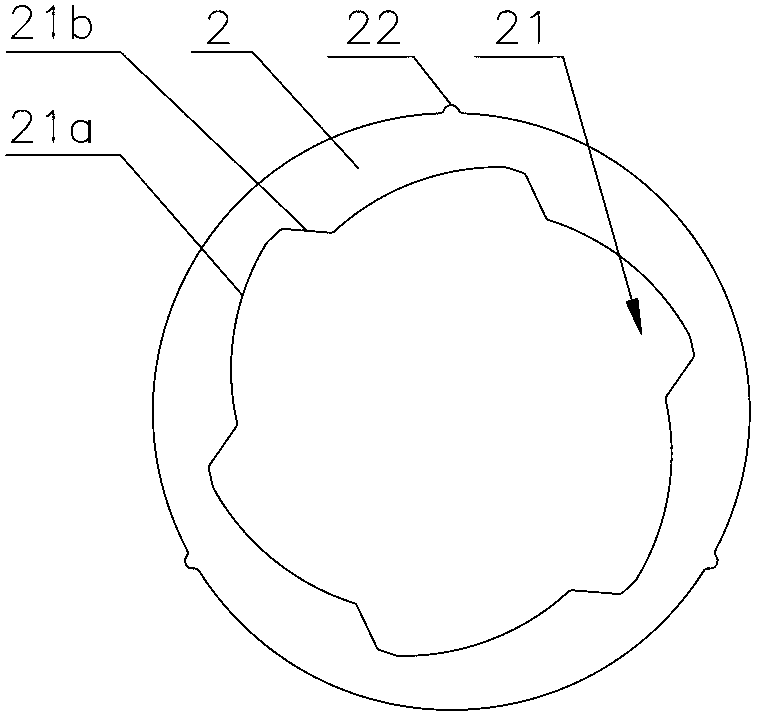

[0021] The starting claw plate of the present embodiment includes a starting plate 1 and a claw ring 2. The starting plate 1 includes a frustum-shaped bowl 11 and an annular portion 12 connected to the large end of the bowl 11. The conical surface of the bowl 11 has a plurality of Evenly distributed through holes 111, the bottom surface of the bowl 11 has a shaft hole 112, the inner wall of the claw ring 2 has multiple claw grooves 21 uniformly distributed in the same direction, and the claw grooves 21 are smoothly transitioned from the arc surface 21a to the groove bottom surface 21b The groove bottom surface 21b is in surface-to-surface contact with the top surface of the starting claw head. There are three outwardly concave first grooves 121 on the inner wall of the ring part 12. The first grooves 121 are evenly distributed on the ring. The inner wall of the part 12 and the outer wall of the claw ring 2 have a first protrusion 22 corresponding to the first groove 121, and th...

Embodiment 2

[0023] The difference between embodiment 2 and embodiment 1 lies in the connection between the claw ring 2 and the starter plate 1. In this embodiment, there are three second protrusions 122 protruding inward on the inner wall of the ring part 12, and the second protrusions 122 are Evenly distributed on the inner wall of the ring portion 12 , the outer wall of the claw ring 2 has a second groove 23 corresponding to the second protrusion 122 , and the second protrusion 122 is fitted with the second groove 23 .

[0024] The present invention is described with embodiment 1, the starting pawl plate of embodiment 1 is installed in the diesel engine, and the diesel engine is started by using a conventional starter. There are two starting pawls 3 in the starter, and these two starting pawls 3 are used To snap into the starting claw plate and then drive the diesel engine to start, such as Figure 6 As shown, after the starting claw 3 is thrown out at high speed, the top surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com