Photoelectric stabilized platform assembly zero calibration method

A photoelectric stabilization platform and zero calibration technology, applied in measuring devices, instruments, etc., can solve problems such as installation errors, and achieve reliable measurement and calibration results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

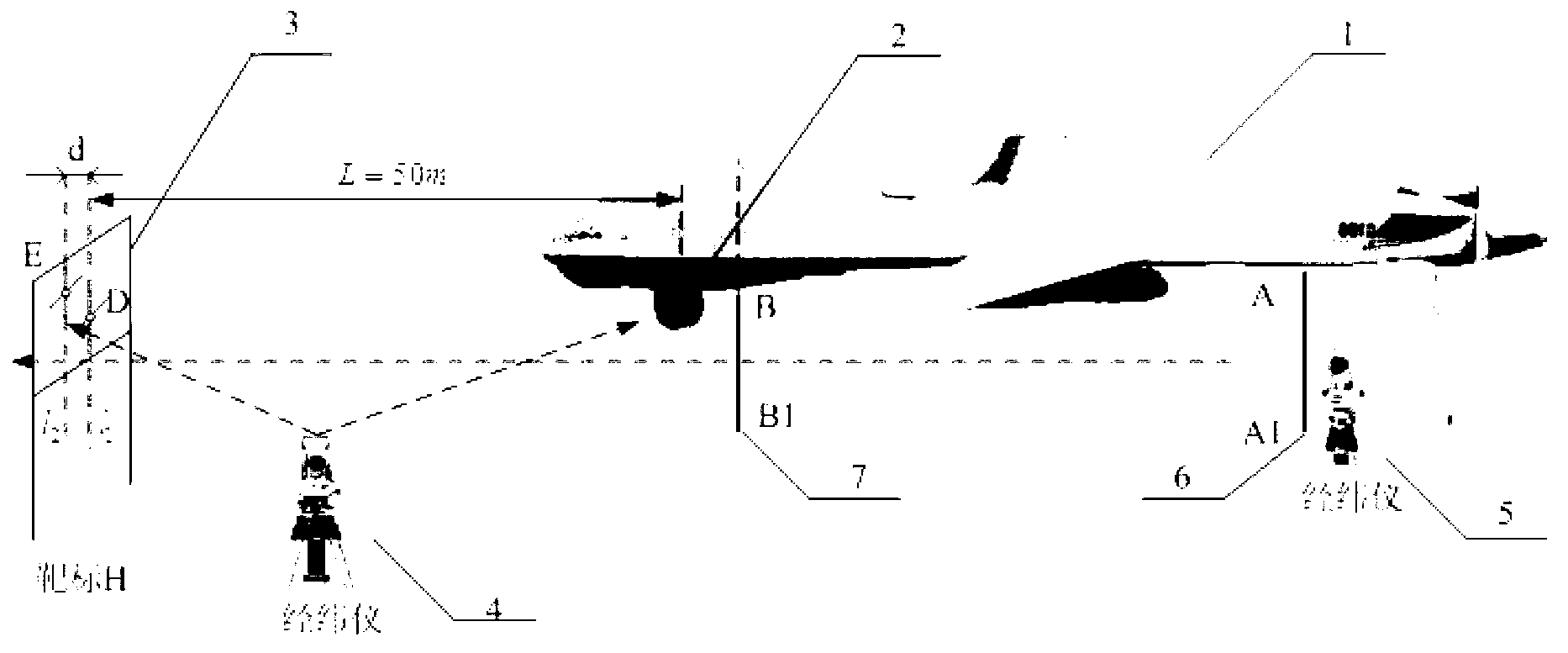

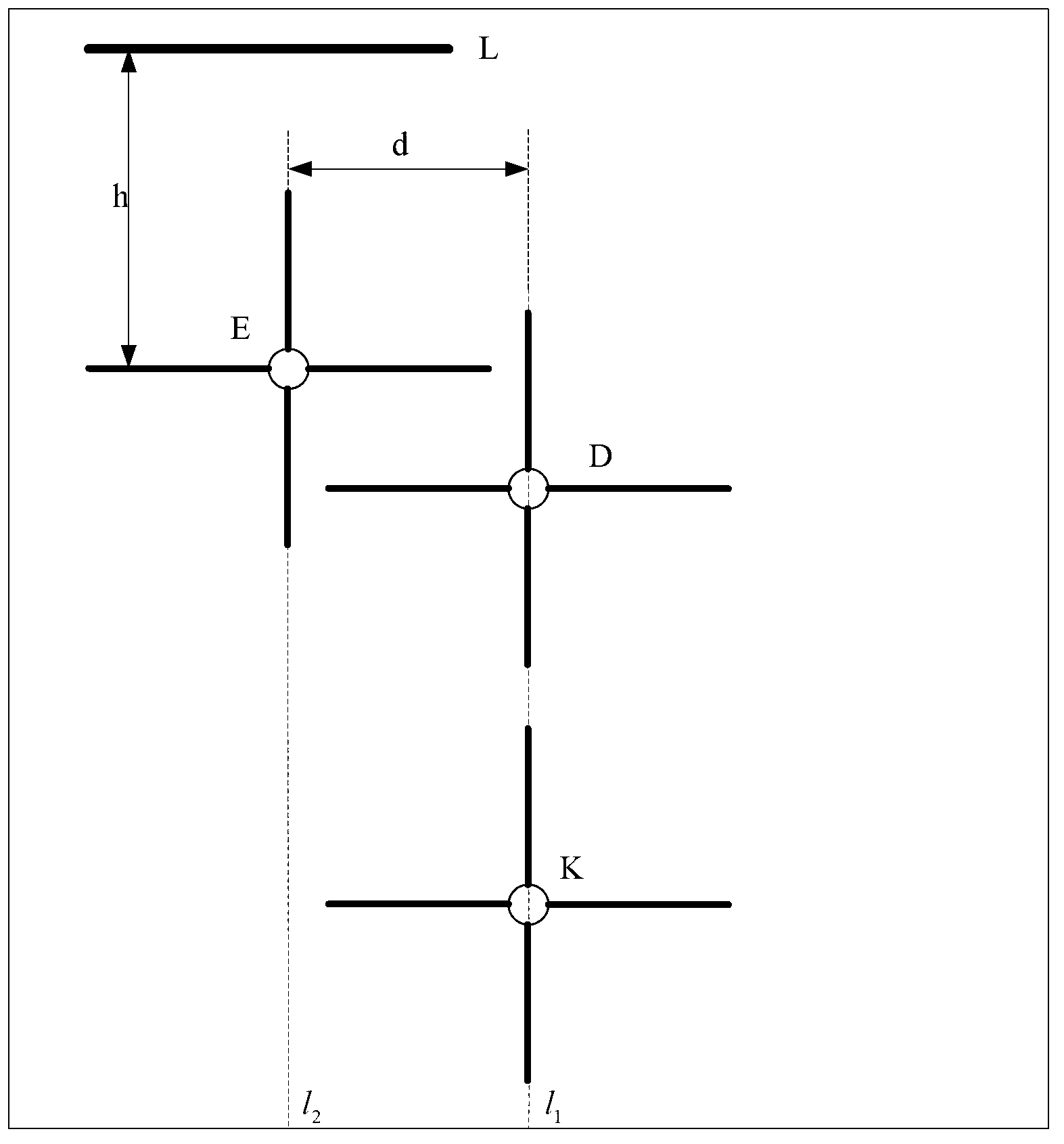

[0022] The calibration system applicable to the installation zero calibration method of the photoelectric stabilized platform of the present invention includes: an aircraft, a photoelectric stabilized platform, a target, a theodolite and theodolite, a plumb line and a plumb line. The position and connection relationship of each part is: the photoelectric stabilization platform is installed on the aircraft, and the target is placed 50-100 meters directly in front of the photoelectric stabilization platform. The plumb line and the plumb line are respectively placed from point A and point B on the aircraft. The intersection points of the two plumb lines and the ground are A1 and B1 respectively. The theodolite is placed at point A1 to measure whether the two plumb lines and the vertical line l1 on the target are on the same straight line. The theodolite is placed on the target and The middle position of the photoelectric stabilized platform is used to measure whether the center of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com