Gas drainage pipeline parameter measuring method

A technology for parameter measurement and gas drainage, applied in measuring devices, measuring fluid pressure, pressure difference measurement between multiple valves, etc., can solve the problem of no integrated temperature probe, unstable differential pressure measurement, long pressure hose Jitter and other problems, to reduce the influence of human factors, lower the lower limit of measurement, and avoid signal fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

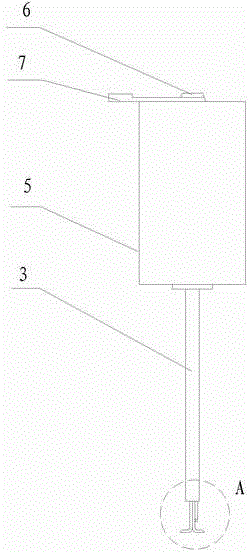

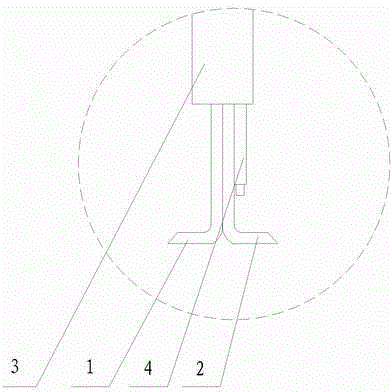

[0019] The gas drainage pipeline parameter measurement method includes a parameter measuring instrument. The parameter measuring instrument includes a measuring device and a pitot tube connected to the fluid signal input port of the measuring device. The pitot tube includes a protective tube 3, a hollow L-shaped pressure guiding tube I1 and Hollow L-shaped pressure guide tube II2, one end of pressure guide tube I1 and pressure guide tube II2 is the inlet port, the other end of pressure guide tube I1 and pressure guide tube II2 is the fluid signal output port, the inlet port of pressure guide tube I1 and the guide port The direction of the inlet port of the pressure tube II2 is opposite, the fluid signal output ports of the pressure guiding tube I1 and the pressure guiding tube II2 are connected to the fluid signal input port of the measuring device, and the protective tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com