Test equipment and test methods for induction hardening machine sensors

A technology of testing equipment and quenching machine, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve problems such as bulges, ground faults, bursts, etc., and achieve the effect of meeting the test requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

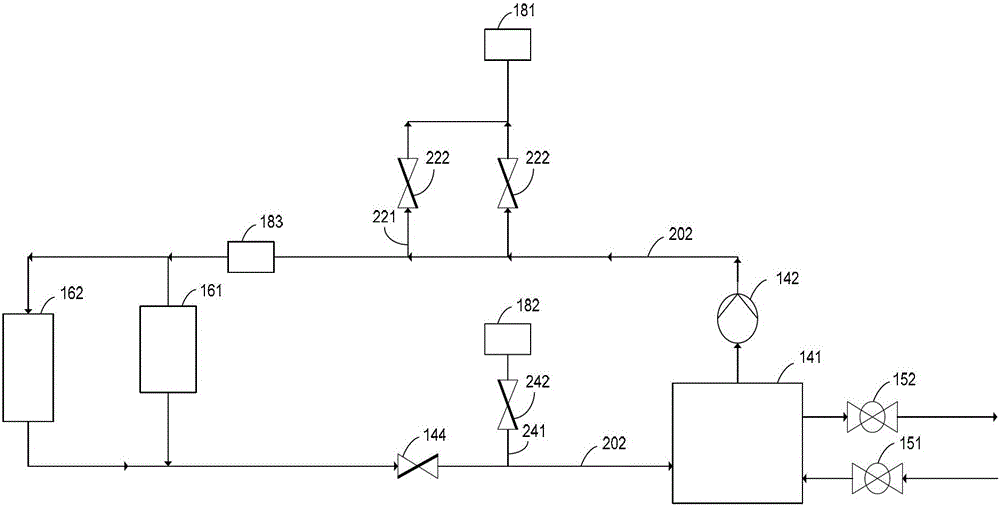

[0024] The test equipment for the induction hardening machine sensor provided by the present invention is a set of simulation test system, which can be considered as an induction type for the simulation test of the internal circulation liquid system of the actual processing condition for the sensors of various induction hardening equipment. Auxiliary equipment and testing equipment for quenching equipment.

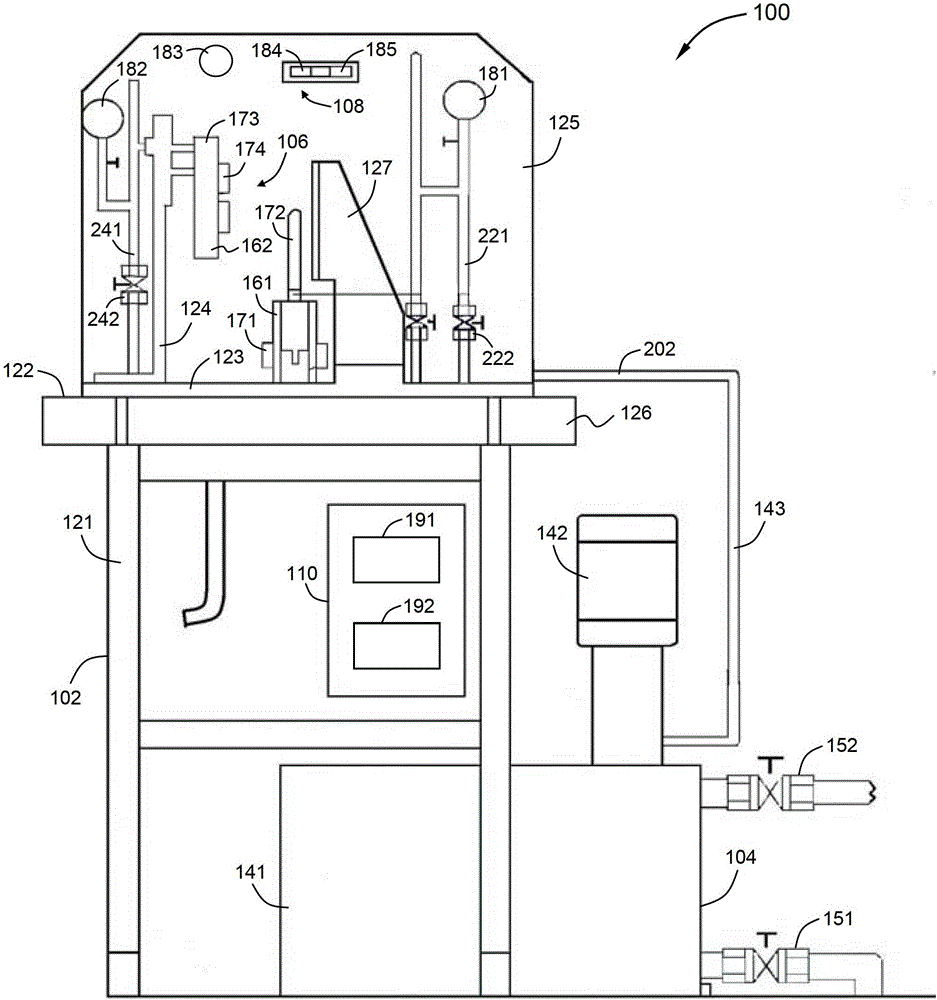

[0025] figure 1 Disclosed is a structural diagram of testing equipment for induction hardening machine inductors according to an embodiment of the present invention. refer to figure 1 As shown, the test equipment 100 for induction hardening machine sensors includes: a frame 102 , a liquid circulation device 104 , an installation mold 106 , an indicating device 108 and an electrical control device 110 .

[0026] The frame 102 has legs 121 on which a workbench 122 is erected, and the workbench 122 is supported by the feet 121 . The workbench 122 includes a horizontal base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com