Cylindrical shallow layer sediment sampler

A sampler and sediment technology, which is applied in the fields of environmental science, biological engineering, environmental engineering, water supply and drainage science and engineering, can solve the problems of uncertain fracture location, easy compression, and damage to the original properties of sediment, and achieves The effect of ensuring sample integrity, preventing sample shedding, and reducing compression damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

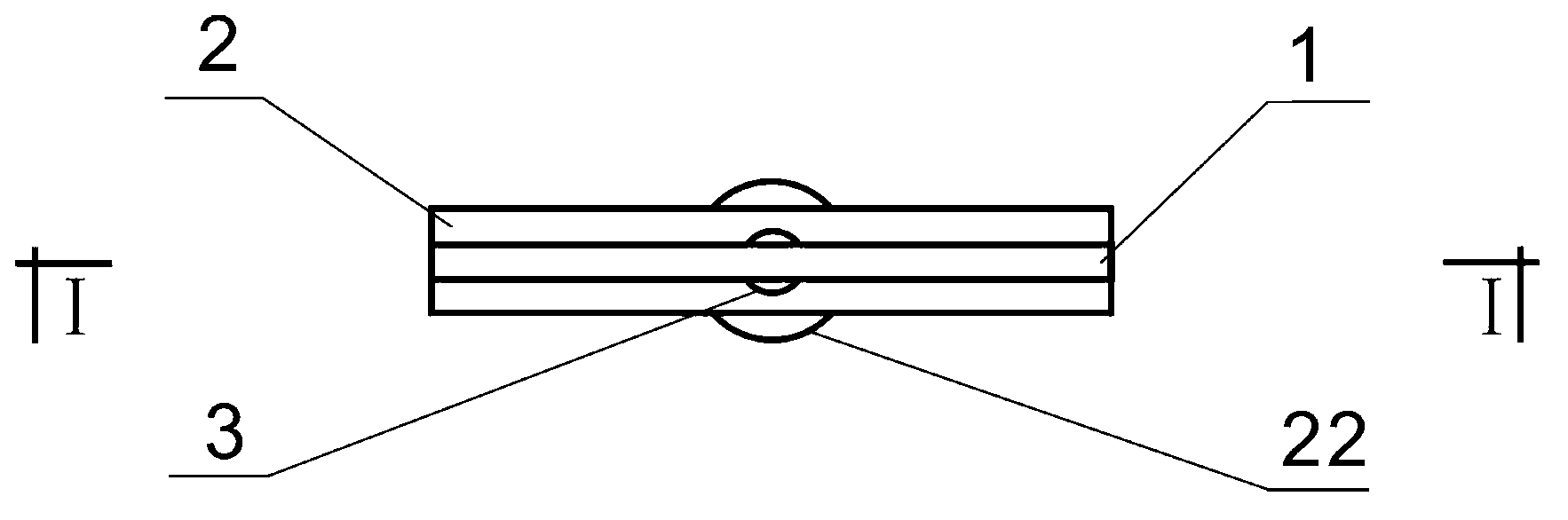

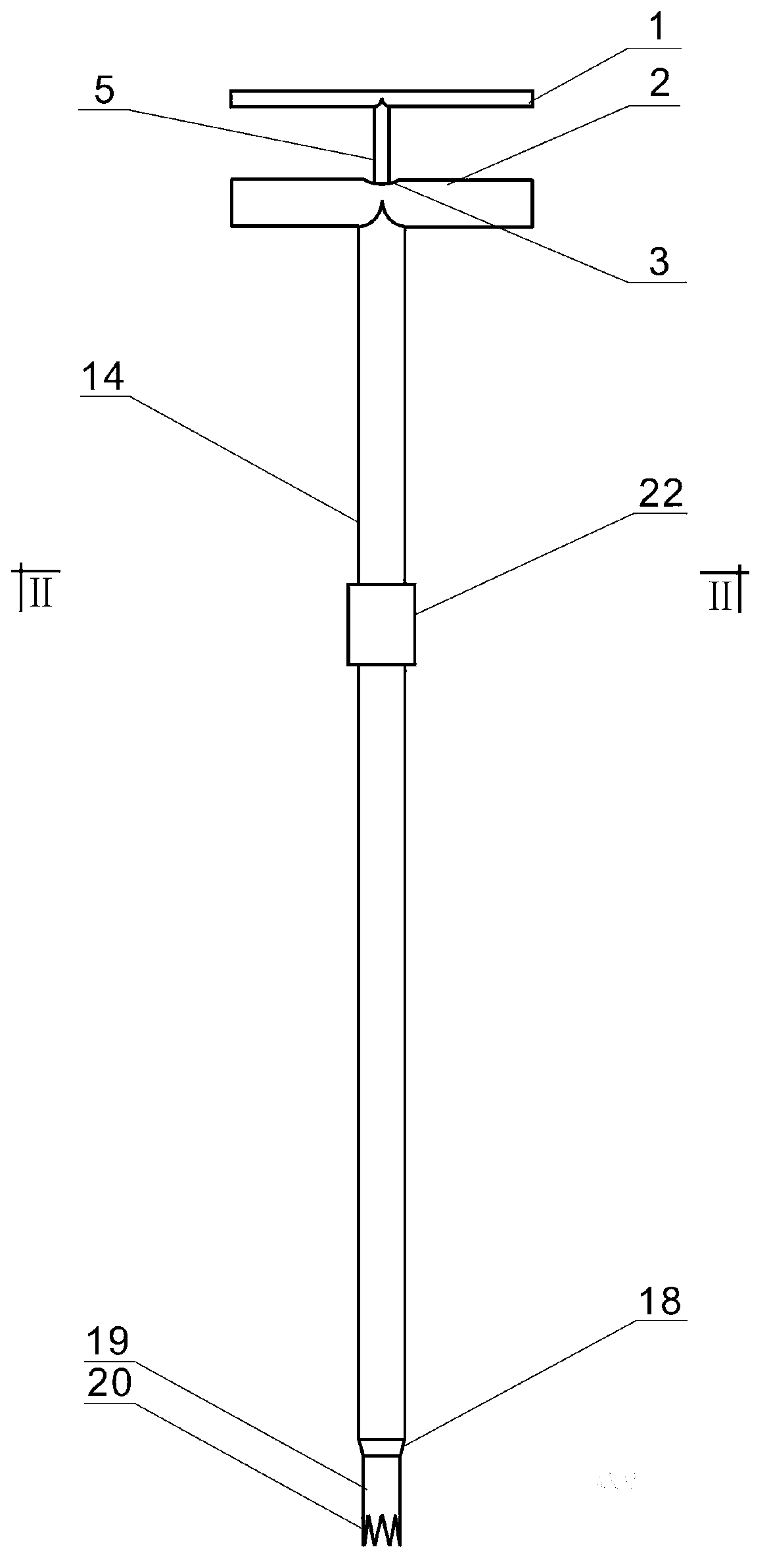

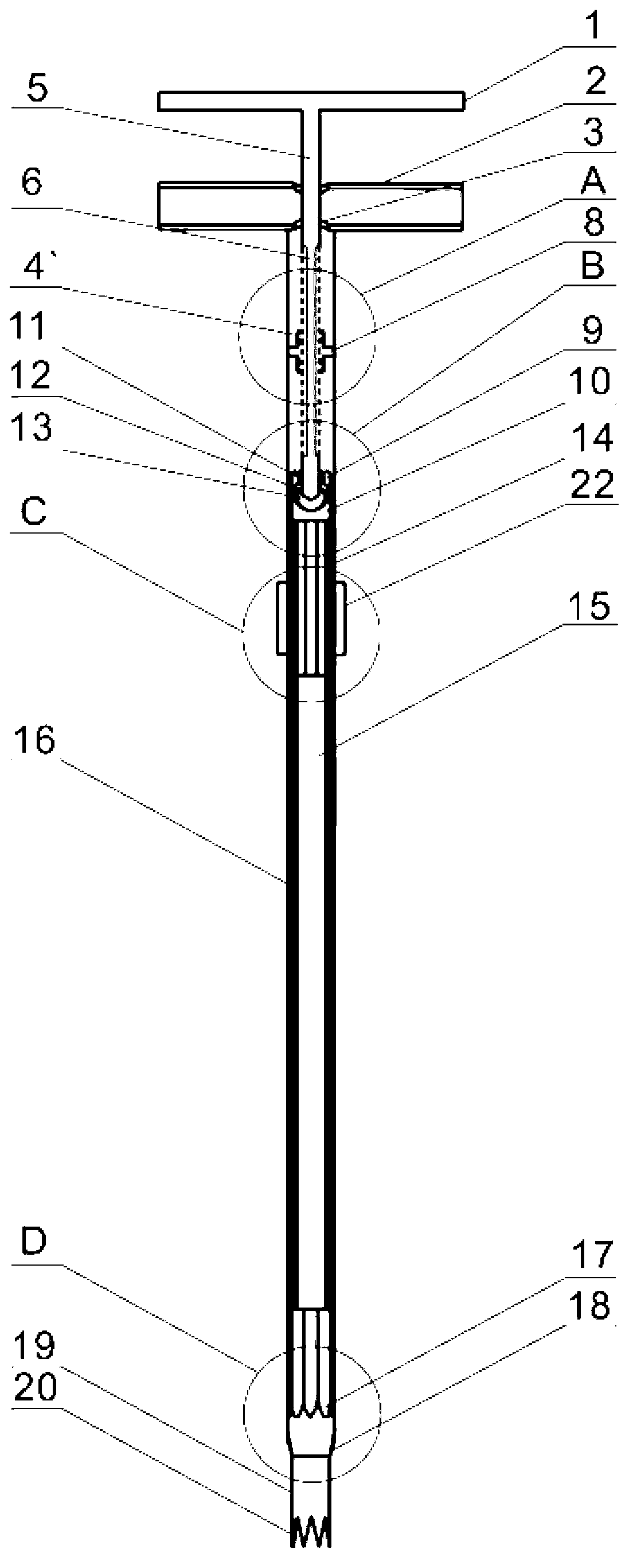

[0016] see Figure 1-Figure 9 :

[0017] The invention consists of a bottom mud sampling device and a bottom mud sample cutting and packaging device set in the bottom mud sampling device. The bottom mud sampling device includes a lower handle 2, an outer sleeve 14, a guide 18 and a sampling head 19 connected in sequence; The ball 13, the inner driving rod 5 and the fixed nut 4 arranged on the inner hole of the outer sleeve 14 are threadedly connected, and the downward movement of the inner driving rod 5 and the rolling ball 13 drives the upper driving block 9, the lower driving block 10, and the inner sleeve 15 , the barrier block 21, the driving piece 16, and the cut-off cutter head 17 move down, and the lower part of the cut-off cutter head 17 is gradually turned inward and closed by the limit of the guide 18, and the upper handle 1 is located between the upper end surface of the sediment sampling device superior.

[0018] Such as figure 1 , figure 2 , image 3 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com