High impedance shell type transformer

A shell-type transformer and high-impedance technology, applied in the field of transformers, can solve the problems of increasing materials and increasing the cost of impedance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

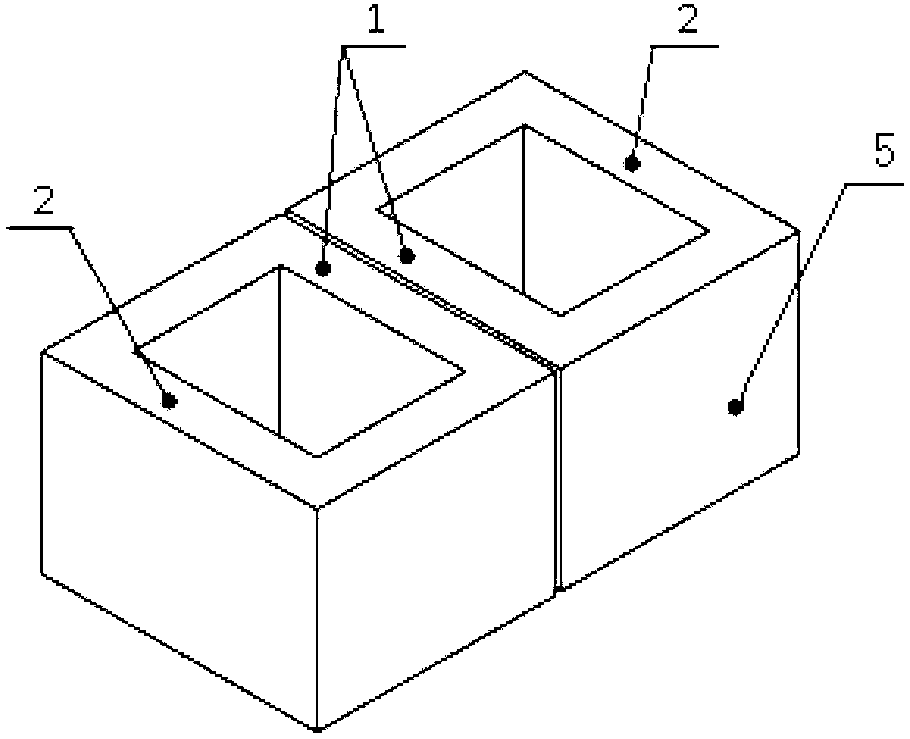

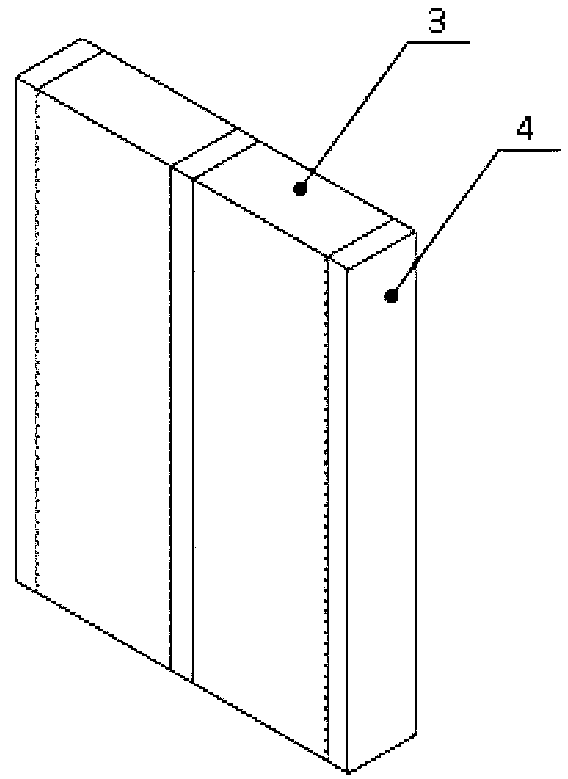

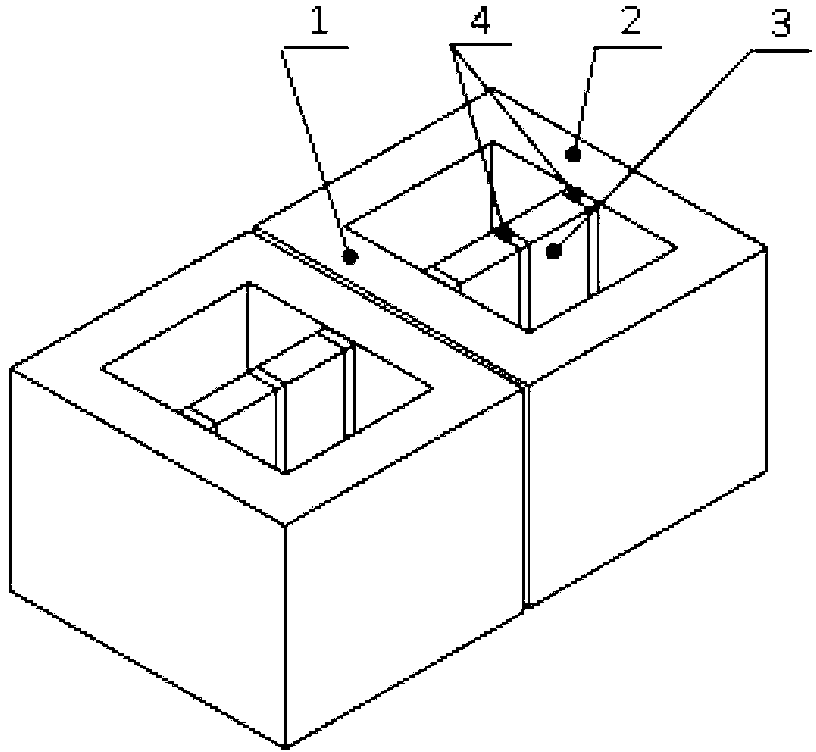

[0028] The inventor found through theoretical analysis and a large number of experiments that after installing a magnetic flux leakage gap core composed of a magnetically permeable material and a gap backing plate in the magnetic flux leakage cavity of the shell-type transformer, a part of the magnetic flux leakage still passes through the insulating medium (air, oil, etc.) to form a closed circuit; a part of the core passes through the core column 1 and the iron yoke 2 from the gap of the magnetic flux leakage channel to form a closed circuit, and its magnetic field lines are as follows Figure 6 The magnetic field line 9 of the transformer leakage flux is shown. The transformer impedance is proportional to the magnitude of the leakage flux, and the flux is proportional to the permeability. The magnetic permeability of the magnetic permeable material 3 is far greater than that of the insulating medium. Therefore, after the magnetic flux leakage space gap core is installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com