Side-open button

A side-opening button and socket technology, applied in the direction of belt buckles, fasteners, clothing, etc., can solve the problems of plug insertion stop, residual habitual deformation, increased resistance in the middle of the engaging part, etc., and achieve light weight, cost reduction, low cost, etc. Cost reduction, steep inclination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

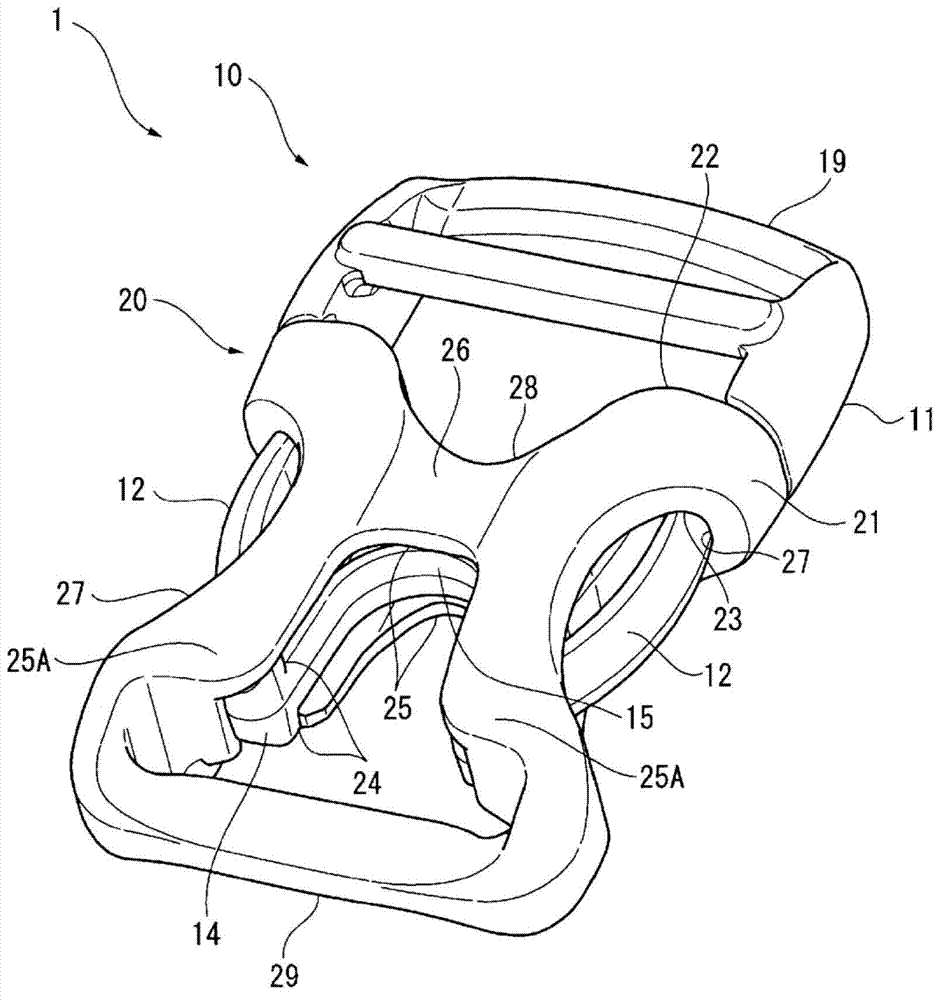

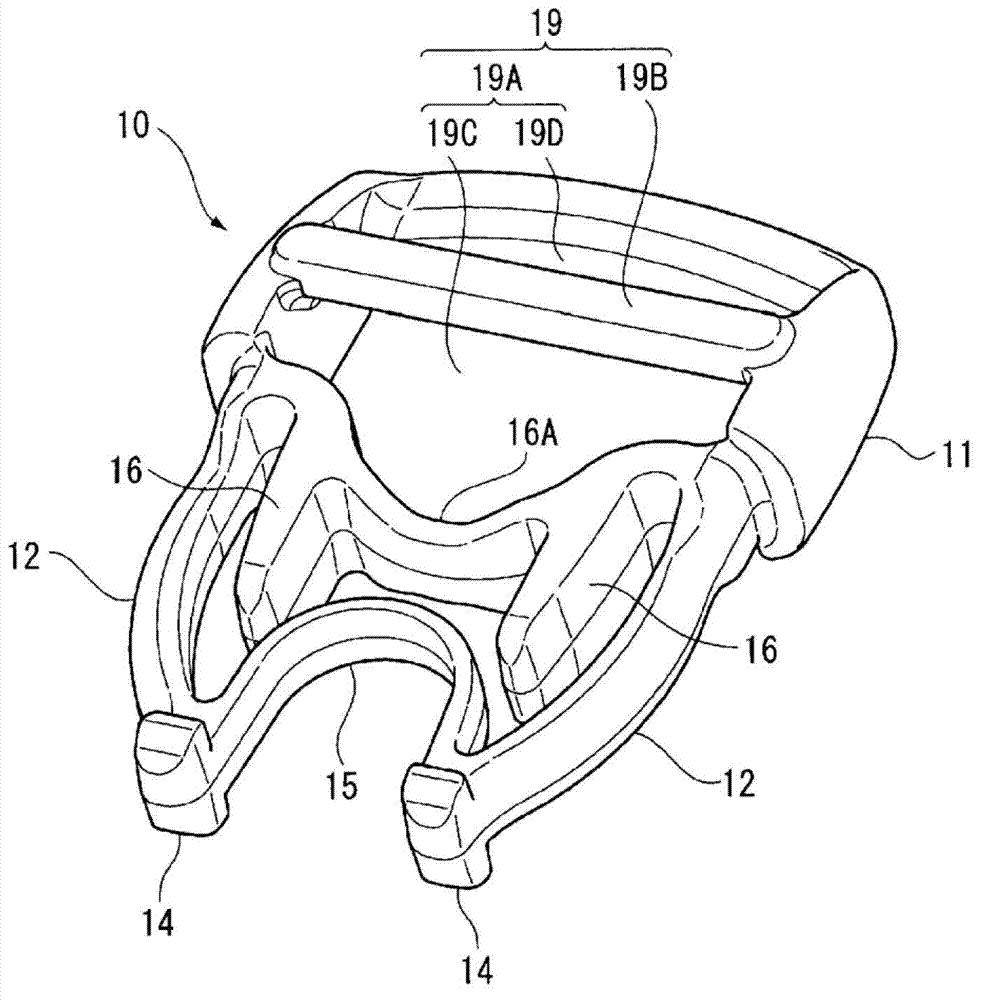

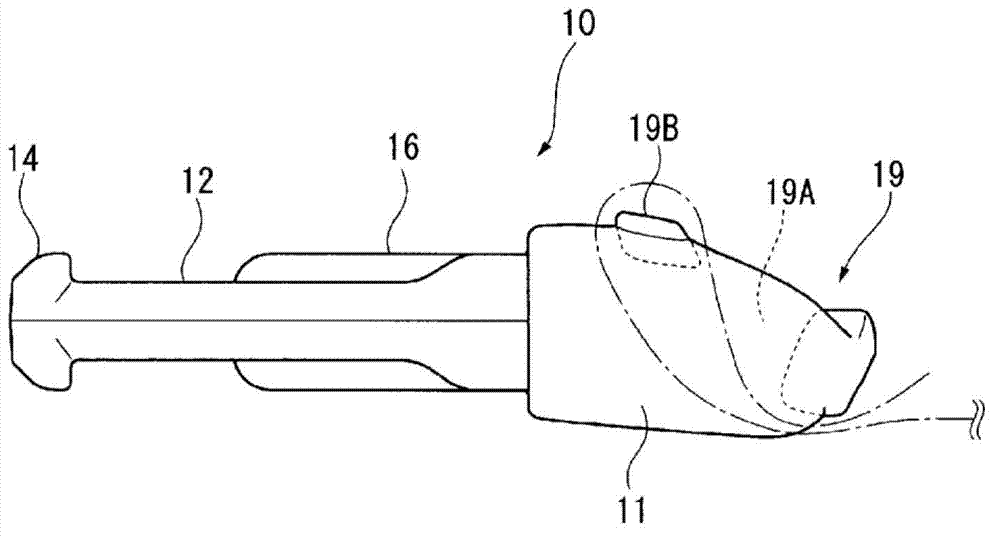

[0052] Figure 1 to Figure 8 The first embodiment of the present invention is shown.

[0053] Such as Figure 1 ~ Figure 3 As shown in the figures, the side release buckle 1 of this embodiment includes a plug 10 and a socket 20 for inserting and engaging the plug 10 .

[0054] As shown in the above-mentioned figures, the side release buckle 1 of this embodiment is used to connect or separate the ends of string-like members such as belts. The side release buckle 1 includes a plug 10 integrally formed with synthetic resin, and Similarly, the socket 20 integrally molded with synthetic resin is used. In addition, the material of the plug 10 and the socket 20 is not limited to synthetic resin, and other materials such as metal may also be used. The molding method of the plug 10 and the socket 20 is not limited to injection molding, and may be formed by other molding methods.

[0055] exist figure 1 with figure 2 Among them, the plug 10 is integrally formed by injection moldin...

no. 2 Embodiment approach

[0100] Figure 9 The second embodiment of the present invention is shown.

[0101] The side release buckle 2 of this embodiment includes the same plug 10 and receptacle 20 as those of the above-mentioned first embodiment. However, in this embodiment, the area allocation method of the guide surface 30 in the receptacle 20 is different from the above-mentioned first embodiment.

[0102] exist Figure 9 In this embodiment, the section S2 of the guide part 32 is enlarged, and the section S3 of the introduction part 33 is reduced accordingly.

[0103] The introduction part 33 is the same as that of the above-mentioned first embodiment in that it is formed in an arcuate shape and that the inclination angle is A3, but the interval W3 is greatly reduced.

[0104] The structure of the guide part 32 is the same as that of the above-mentioned first embodiment, that is, the pair of guide parts 32 are parallel to each other, the direction D2 of the guide part 32 is the same as the inser...

no. 3 Embodiment approach

[0108] Figure 10 The third embodiment of the present invention is shown.

[0109] The side release buckle 3 of this embodiment includes the same plug 10 and socket 20 as those of the above-mentioned first embodiment. However, in this embodiment, the shape and arrangement|positioning of the introduction part 33 and the guide part 32 differ from the said 1st Embodiment.

[0110] The introduction part 33 of the first embodiment described above is formed in a circular arc shape, whereas the introduction part 33 of the present embodiment is formed in a linear shape. In addition, the end of the introduction portion 33 in the present embodiment on the side of the insertion port 22 is disposed on the edge of the insertion port 22 , and the end portion linearly extends into the storage space 23 along a direction D3 at an oblique angle A3 with respect to the insertion direction D0. , and continuous with the guide portion 32 .

[0111] Whereas the guides 32 of the first embodiment ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com