Carrier trolley device for live cleaning system

A charged cleaning and carrier technology, applied in tracked vehicles, motor vehicles, transportation and packaging, etc., can solve problems such as flashover accidents and the impact on the safe operation of surrounding electrical equipment, and achieve the effect of good mobility and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

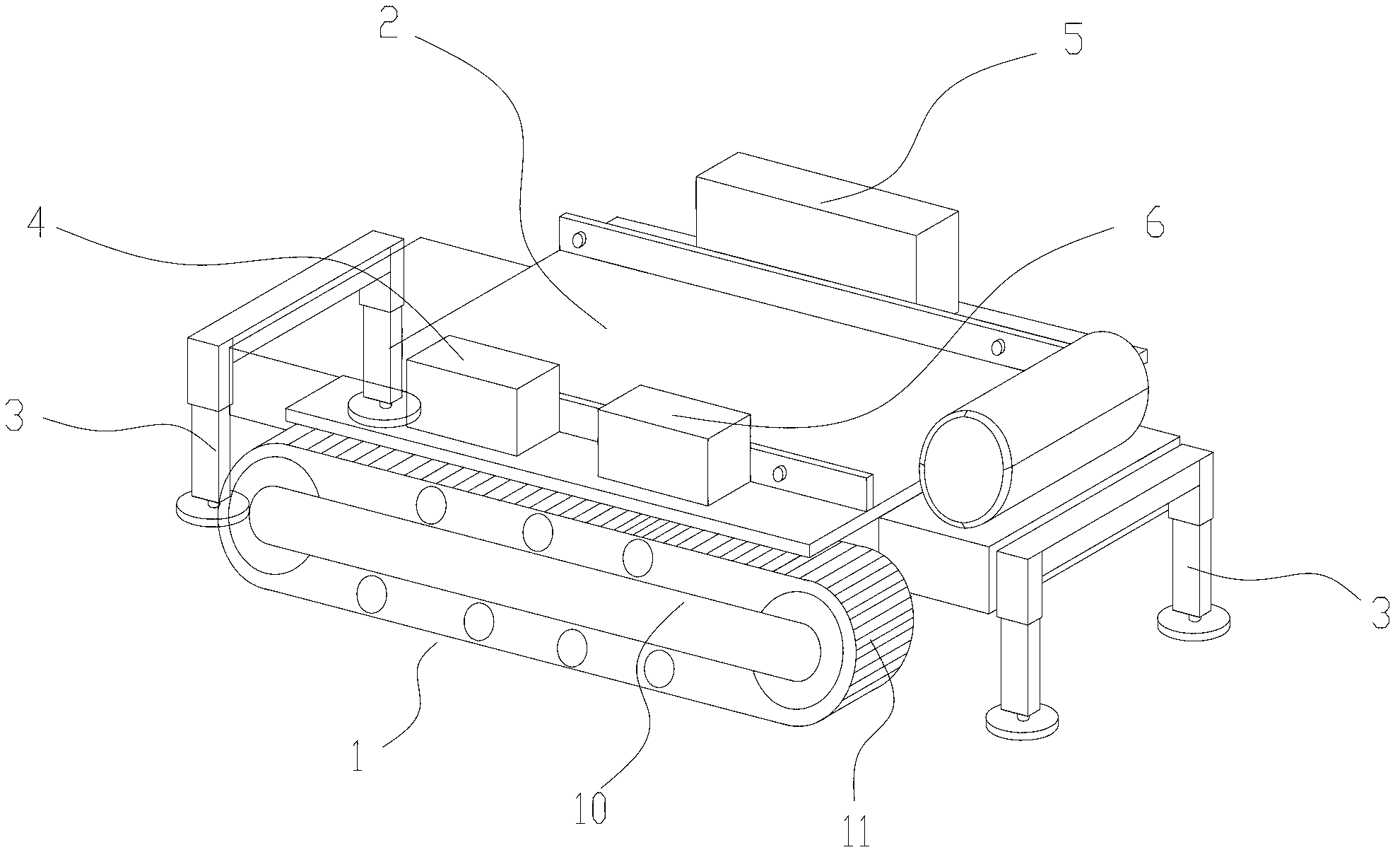

[0014] Such as figure 1 As shown, a carrier trolley device of a charged cleaning system includes a crawler chassis 1 and a carrier platform 2 erected on the crawler chassis, and the front and rear ends of the crawler chassis are provided with self-leveling legs 3, so The carrier platform 2 is provided with a leveling control device 4, the leveling control device 4 is electrically connected to the automatic leveling leg 3, and the length of the automatic leveling leg 3 is adjusted by the leveling control device 4 And the pressure of support provides a stable working platform for the electrified cleaning system.

[0015] figure 1 Among them, two self-leveling outriggers 3 are respectively arranged at the front end and the rear end of the crawler chassis, and the self-leveling outriggers are in a linkage structure, and the leveling control device 4 can automatically judge the inclination angle of the road surface through a sensor, Automatically adjust the protruding length of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com