Precision forging blade thickness plastic deformation compensation method

A technology of plastic deformation and blade thickness, which is applied to the supporting elements of blades, engine elements, machines/engines, etc., can solve the problems of low work efficiency and long manufacturing cycle of precision forging dies, and achieve shortened manufacturing cycle, increased die life, The effect of reducing the number of repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

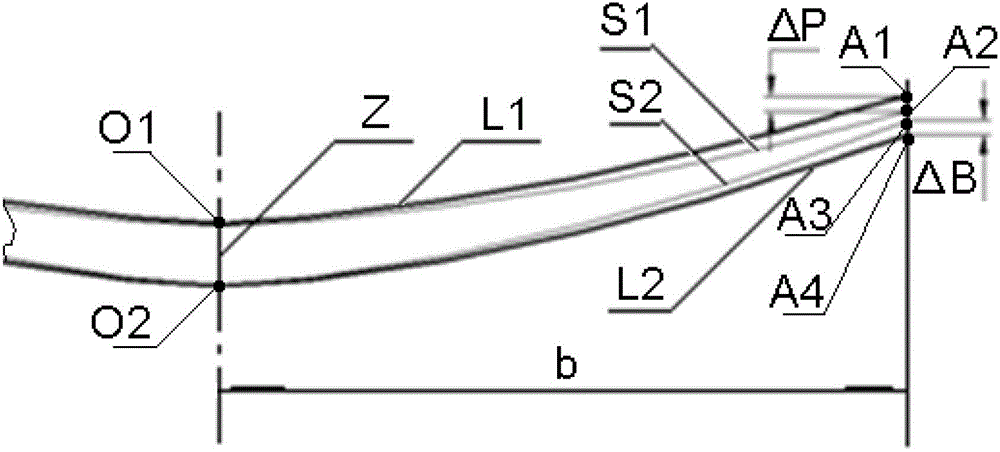

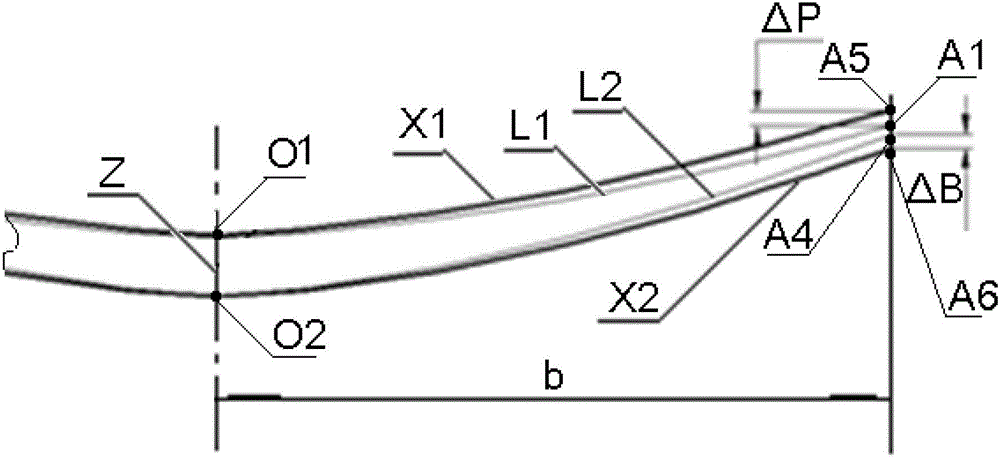

[0020] Example 1, manufacturing a precision forging die for a certain type of aero-engine blade, the half-chord length b of the blade is 14mm, and the initial compensation value ΔP 0 =0.08mm, ΔB 0 =0.1mm, according to the initial compensation amount compensation, the mold is used for trial forging, and the three-coordinate measuring machine is used for detection, ΔP 1 and ΔB 1 If it is less than 0.01mm, use the initial compensation surface as the mold parameter to make the mold.

Embodiment 2

[0021] Example 2, manufacturing a precision forging die for a certain type of aero-engine blade, the half-chord length b of the blade is 31mm, and the initial compensation value ΔP 0 =0.11mm, ΔB 0 =0.14mm, according to the initial compensation amount compensation, the mold is subjected to trial forging, and the three-coordinate measuring machine is used for detection, ΔP 1 =0.04mm and ΔB 1 =0.03mm, then repeat steps 1.2 to 1.4 to get the compensation value ΔP for the next test forging 2 and ΔB 2 If it is less than 0.01mm, use the first compensation surface as the mold parameter to make the mold.

Embodiment 3

[0022] Example 3, manufacturing a precision forging die for a certain type of aero-engine blade, the half-chord length b of the blade is 57mm, and the initial compensation value ΔP 0 =0.16mm, ΔB 0 =0.22mm, according to the initial compensation amount compensation, the mold is used for trial forging, and the three-coordinate measuring machine is used for detection, ΔP 1 = 0.07mm and ΔB 1 = 0.06mm, then repeat the method from step 1.2 to step 1.4 to get the compensation value ΔP for the next trial forging 2 =0.03mm and ΔB 2 =0.03mm, then repeat the method from step 1.2 to step 1.4, ΔP 3 and ΔB 3 If it is less than 0.01mm, use the second compensation surface as the mold parameter to make the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com