Hydrodynamic wind power propulsion device and cooling tower wind power system

A propeller and wind power technology, which is applied to water shower coolers, heat exchanger types, machines/engines, etc., can solve the problems of wasting energy and the ineffective use of surplus power, and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

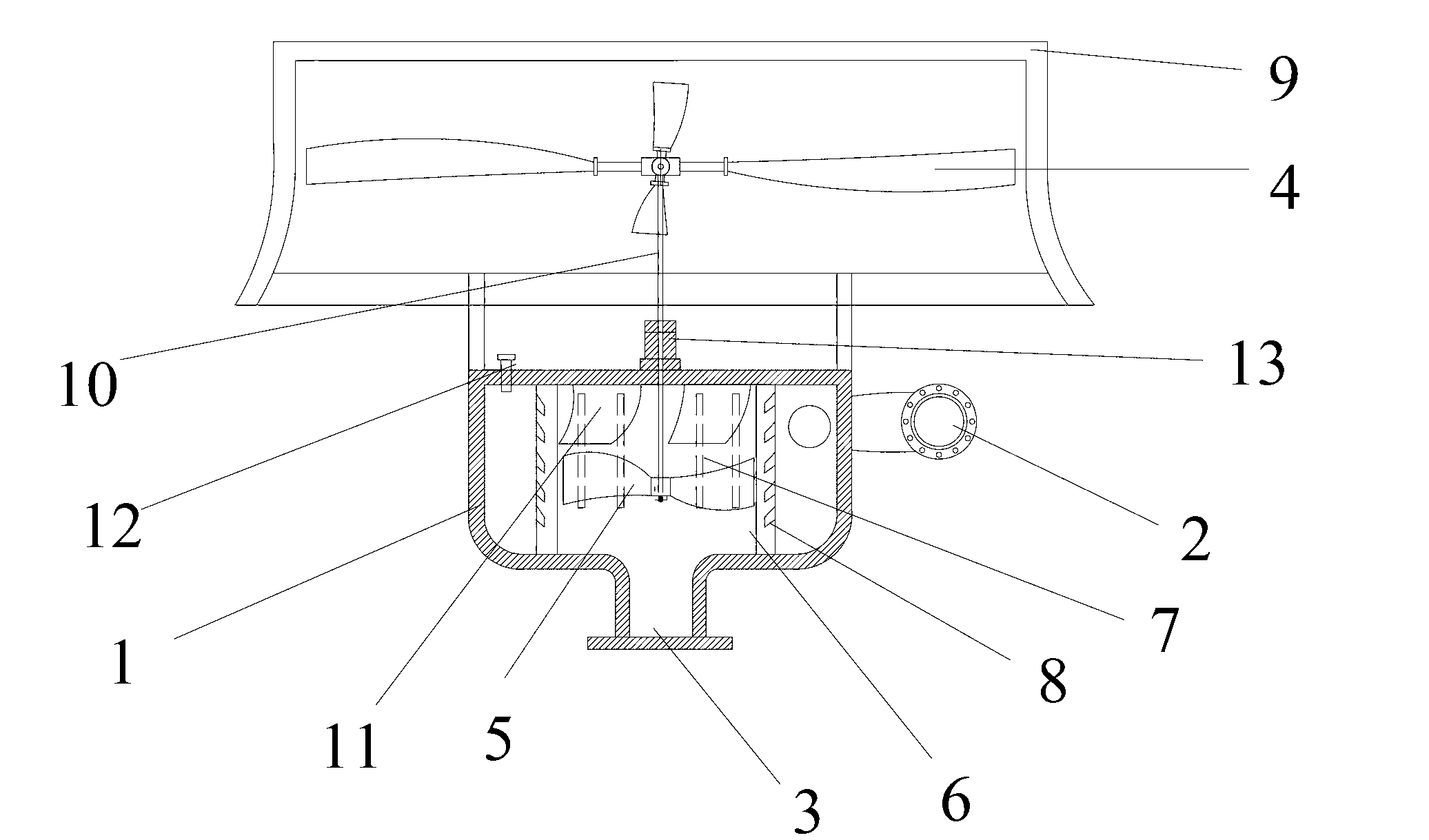

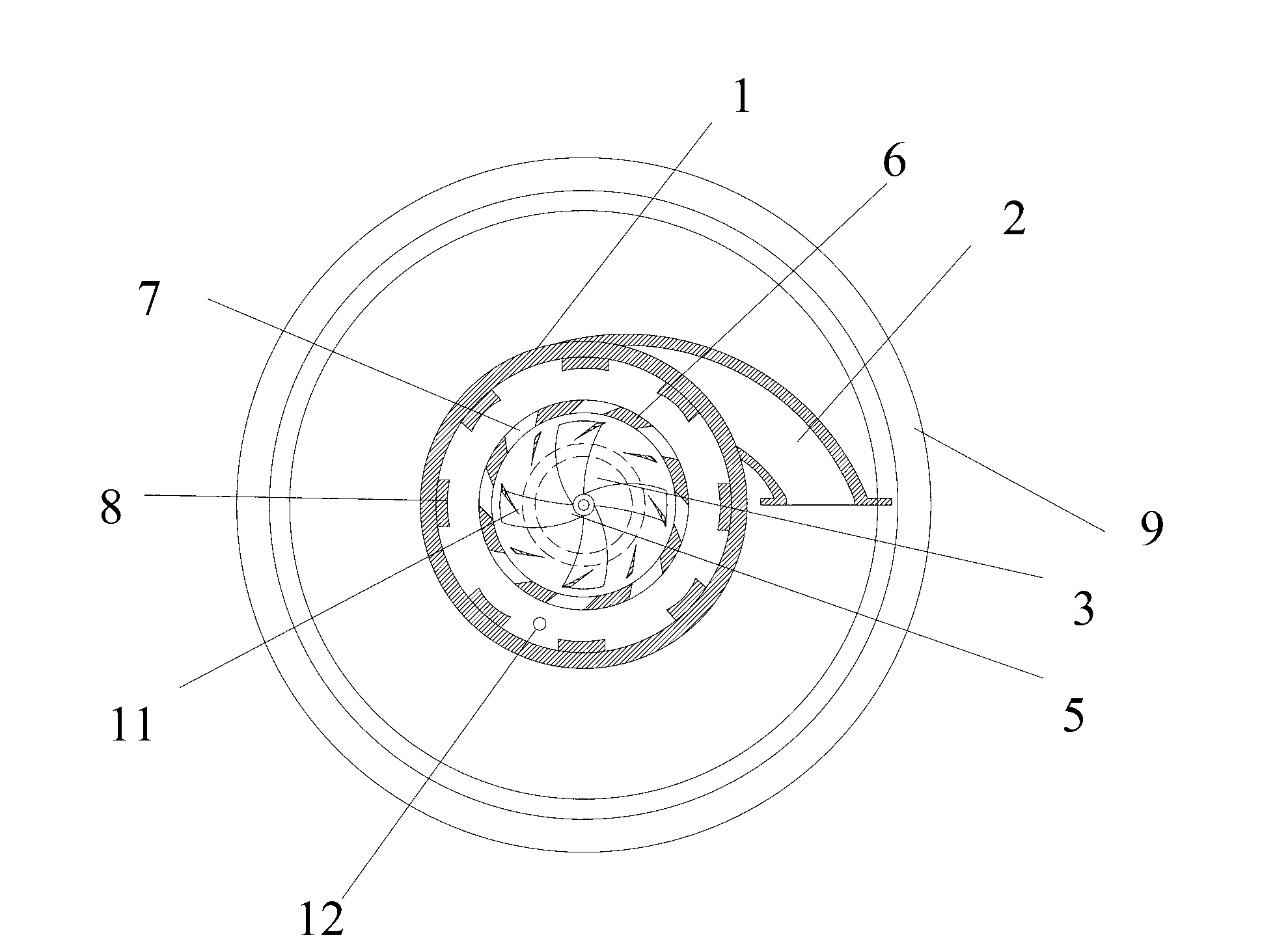

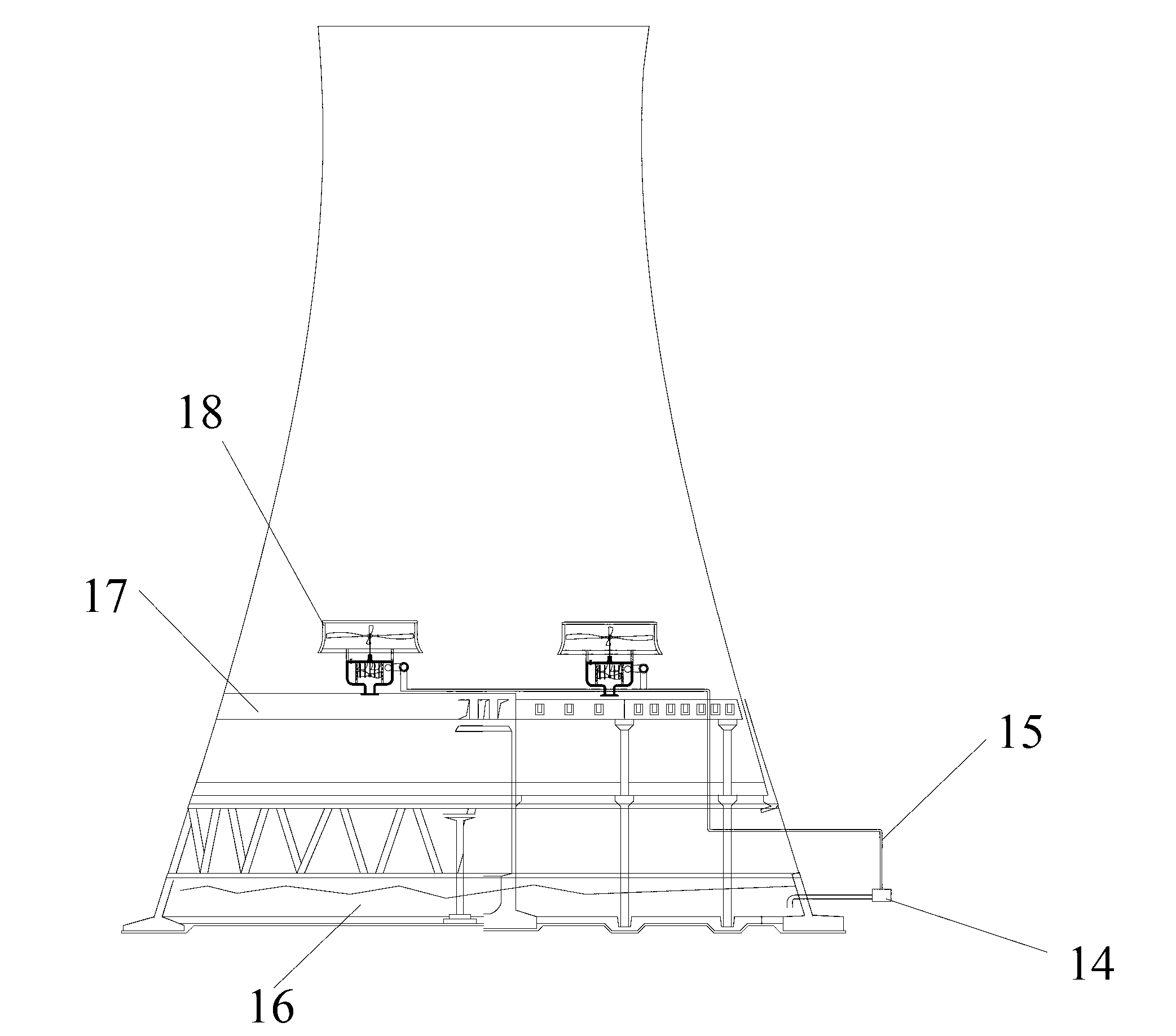

[0019] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0020] Embodiment 1 of the present invention provides a hydrodynamic wind propeller, including a casing, a water inlet, a water outlet, a fan and an impeller; The ends are respectively extended and sealed with the two ends of the casing; the peripheral side of the water collector is evenly arranged with multi-layer water inlet holes along the axial direction of the water collector; the axes of the water inlet holes on the same layer are located in the same horizontal plane, and Each water inlet hole forms the same angle with a straight line extending radially of the water collector and passing through the center of the water inlet hole; the impeller is arranged in the water collector, and the impeller and the water collector are coaxial; the water inlet It is arranged on the side wall of the casing, and the water o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com