High-tension porcelain insulator flaw-detection creeping wave probe clamp

A creeping wave probe and high-pressure porcelain bottle technology, which is applied to instruments, scientific instruments, and material analysis using sound waves/ultrasonic waves/infrasonic waves. Unsatisfactory problems, to achieve the effect of smooth movement of the probe, avoid detection of dead angles, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] Example 1

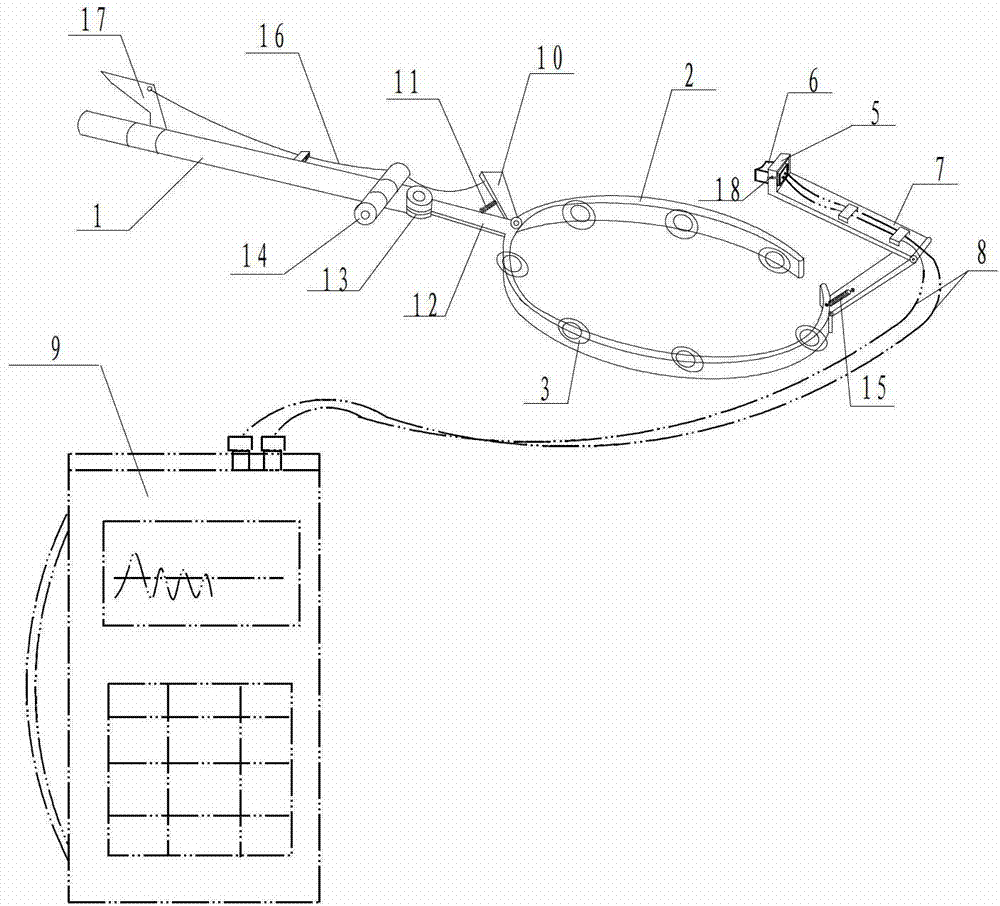

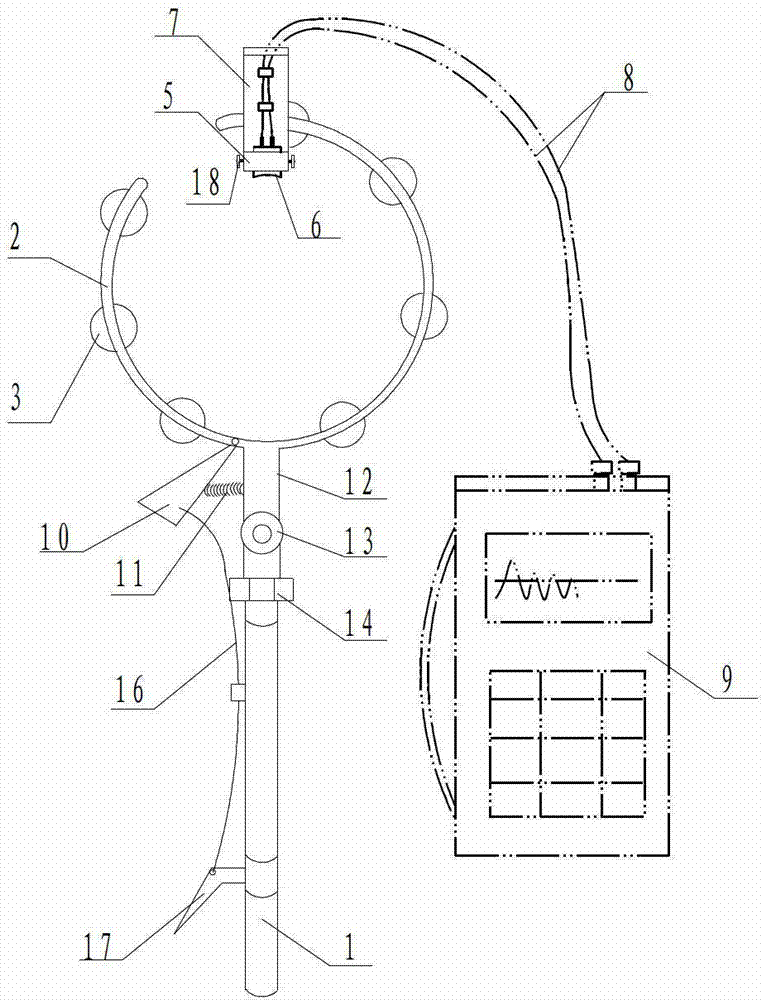

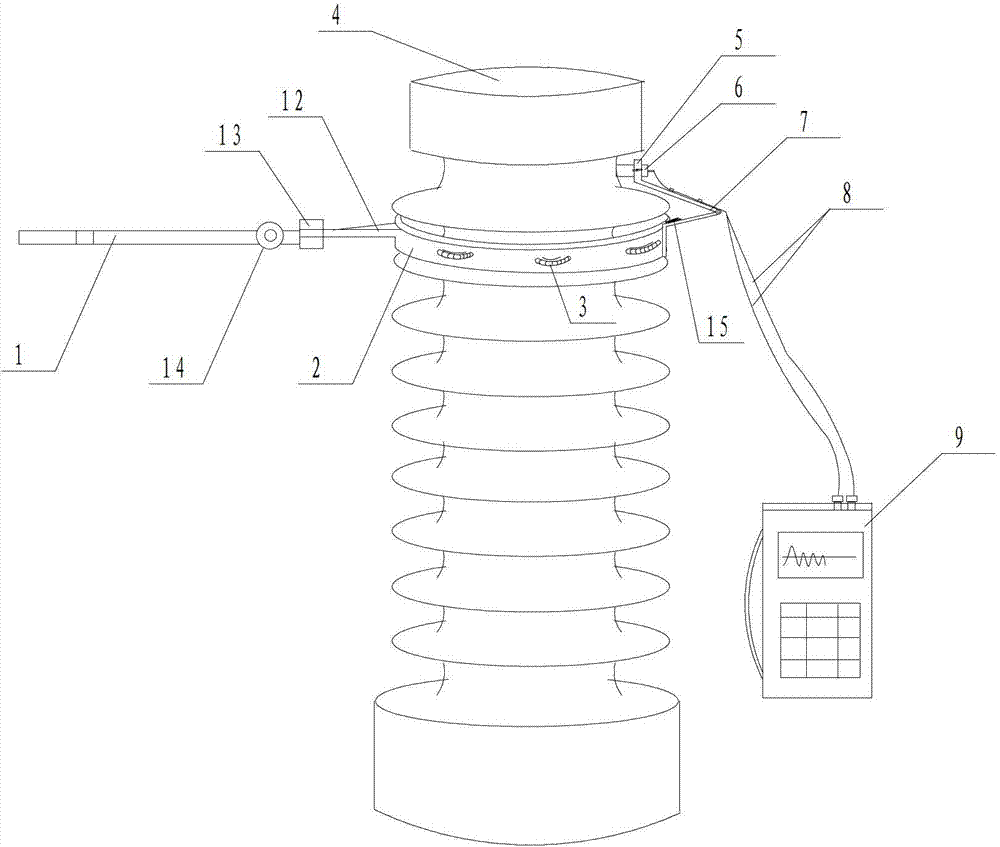

[0020] Kind of like figure 1 The illustrated high-pressure pillar porcelain bottle ultrasonic flaw detection creeping wave probe holder includes a handle 1, a rotating porcelain bottle holder 2, a rubber roller 3, a creeping wave probe holder 5, a creeping wave probe 6, a compression arm 7, a top plate 10, and a back Position spring 11, connecting plate 12, limit hinge 13, folding hinge 14, tension spring 15, thin wire rope 16, opening handle 17, fixing bolt 18.

[0021] The rotating porcelain bottle clamp 2 is equipped with a compression crank arm 7 that can be moved up and down and adjusted. At the top of the compression crank arm 7 is the creeping wave probe fixing seat 5, and the rotating porcelain bottle clamp is opposite to the compression crank arm 7 2 On the other side is a holder handle 1 that can be turned left and right and can be folded up and down. There is also a spreader handle 17 on the holder handle 1 for opening and closing the movable part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com