Magnetic resistance coupling

A coupling and reluctance technology, which is applied in the field of couplings that can use magnetic field buffering, can solve the problems of ordinary couplings, such as easy damage to the buffer pad and small transmission torque, and achieve the effect of small transmission torque and avoiding the use of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Describe an embodiment below in conjunction with accompanying drawing, the present invention is further described.

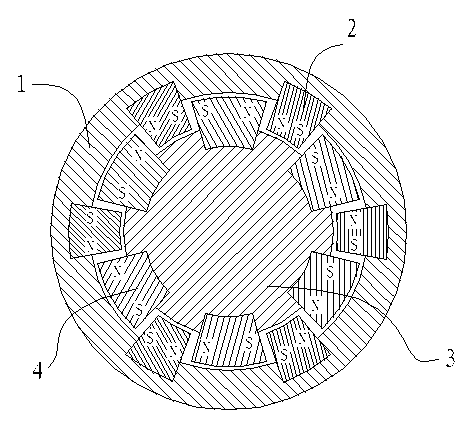

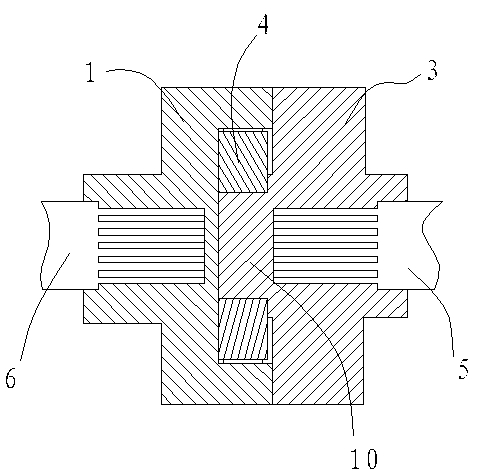

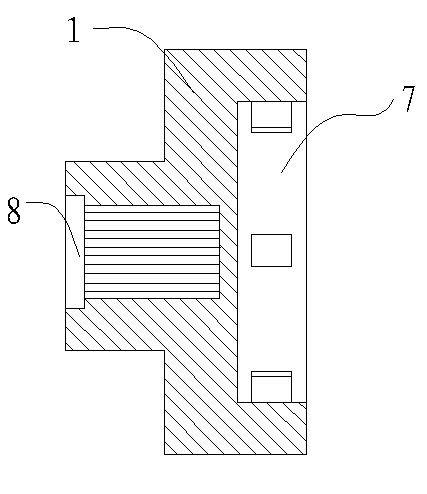

[0018] In the figure, the coupling is composed of a main joint 1 and a slave joint 3, and the end face of the main joint 1 and the slave joint 3 is provided with a circular pit 7, and the axis of the circular pit 7 is in line with the The axis of the main joint 1 is coaxial, and the side walls of the pit 7 are provided with six drive magnets 2, and the drive magnets 2 are evenly distributed along the side walls of the pit 7, and the two adjacent drive magnets 2 There is a gap between them, the matching end surface of the slave joint 3 and the main joint 1 is provided with a pillow block 10, and the side of the pillow block 10 is provided with 6 passive magnetic blocks 4, and the passive magnetic blocks 4 are arranged along the shaft The side walls of the table 10 are evenly distributed, the width of the passive magnetic block 4 is smaller than the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com