Magnetic motor

A magnetic motive and magnetic disk technology, applied in the field of magnetic motive, can solve the problems of not being able to output much power and having no practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

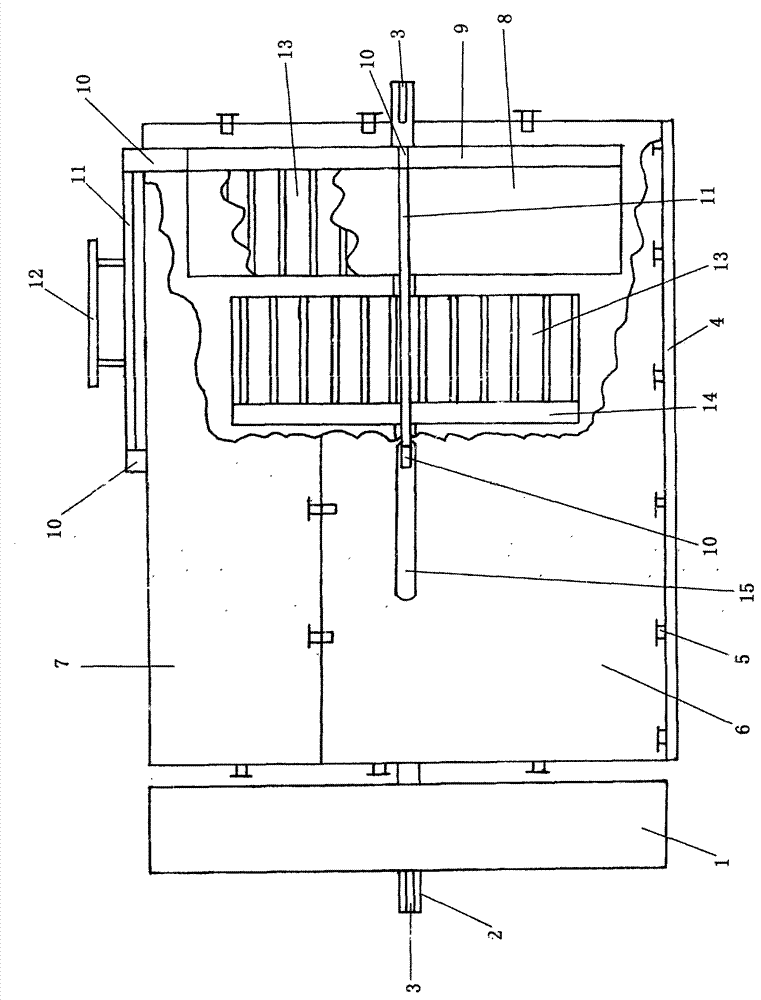

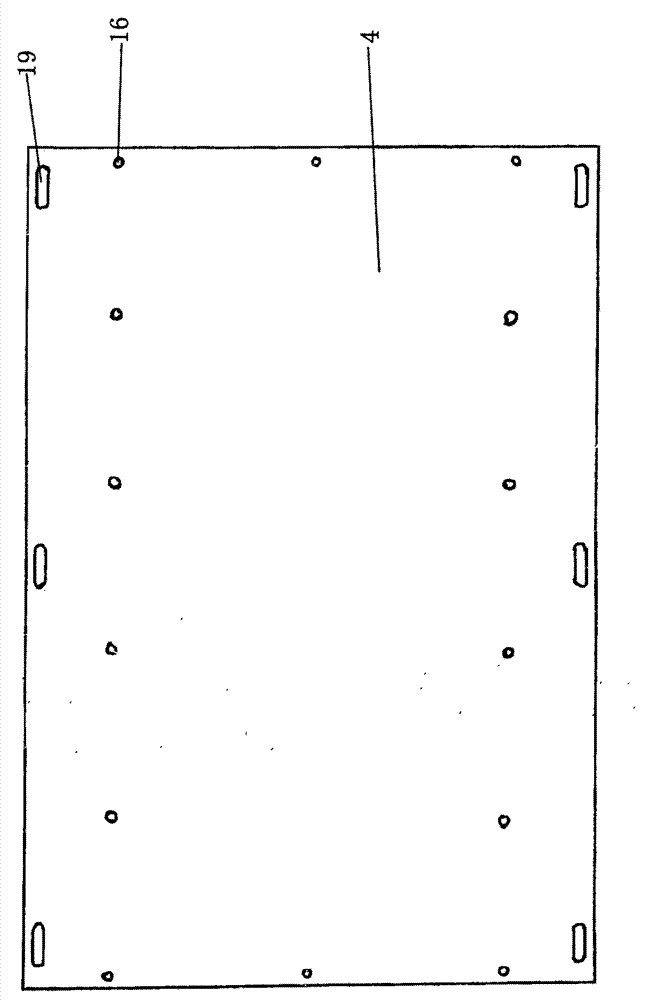

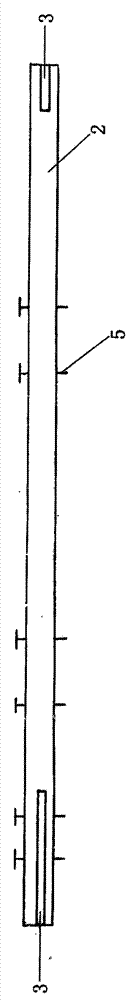

[0007] Specific embodiment: In this embodiment, a dual-disk combination combined with a dual-magnetic coil combination is taken as an example to describe the implementation steps and implementation methods in detail. The first step of parts processing: reference attachment figure 2 Two symmetrical side casing parts 6 are cast out of non-magnetic material. Use a milling machine to mill out two shifting grooves 15 at the position shown in the figure 15, and the left and right positions of the shifting grooves 15 on the other one are opposite. Use a drilling machine to drill four screw holes 16 on the upper butting edge 17, and Drill two screw holes 16 on each of the butt edges 17 at both ends, drill four screw holes 16 on the mounting edge 18, and finally use a tap to tap the threads in all the screw holes 16 to create the side casing part 6 . Reference attachment image 3 Use non-magnetic materials to cast the upper case 7 wool parts. Use a milling machine to mill two shifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com