Super-power loudspeaker

A super-power, loudspeaker technology, applied in sensors, electrical components, etc., can solve problems such as failure to retrieve, and achieve the effect of good heat dissipation, large bonding surface, and not easy to degumming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

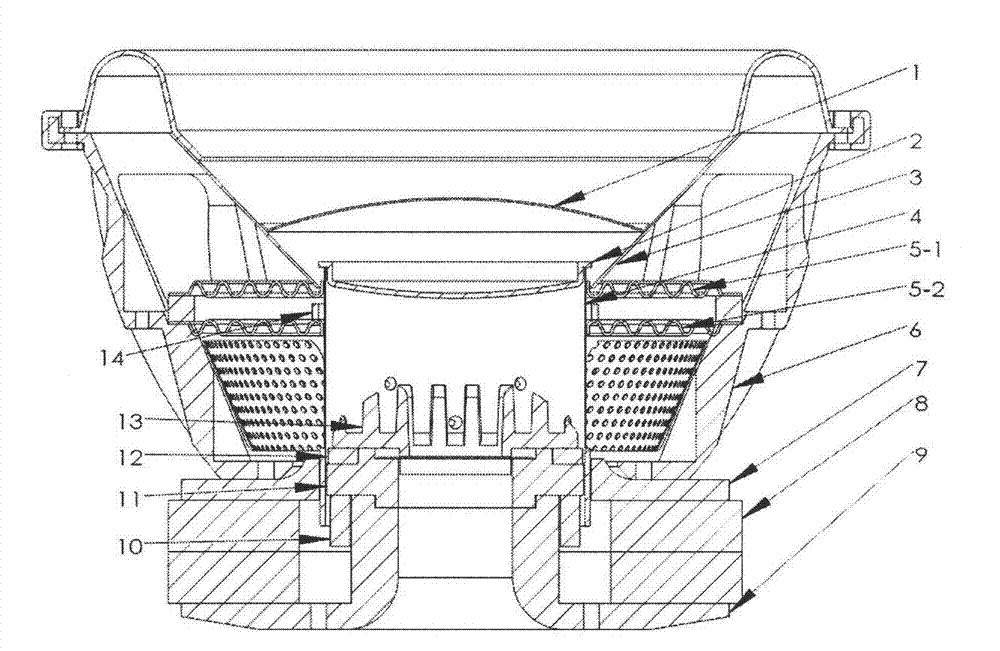

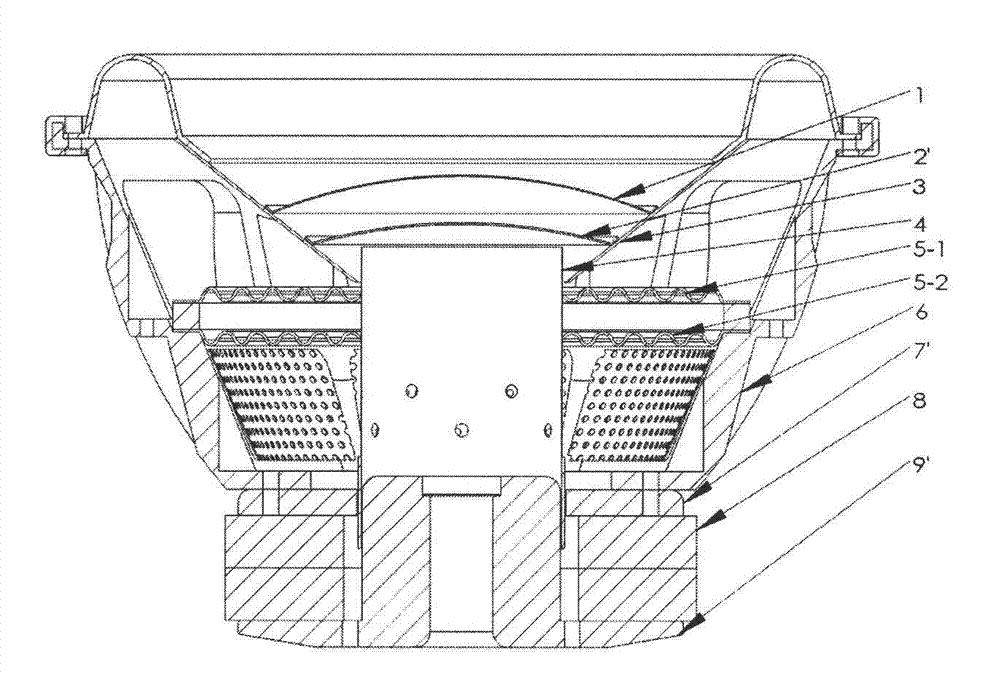

[0015] A super-high-power loudspeaker, comprising at least a pot frame 6, a magnetic steel 8, a T iron 9, a splint 7, a voice coil 4, a paper cone 3, upper and lower dustproof caps 1, 2, and upper and lower spring plates 5-1, 5-2, there is a shaft through hole on the axis of the T iron 9, and there is a group of breathing holes on the voice coil 4, which is characterized in that:

[0016] The lower part of the middle column of the T iron 9 is fitted with a lower short-circuit cooling ring 10, while the upper part of the middle column is fitted with an upper short-circuit cooling ring 12;

[0017] There is an integrated short ring boss on the circumference above the center hole of splint 7;

[0018] The lower dustproof cap 2 has a spherical surface protruding to the inside of the voice coil 4, and its stepped wall matches and is fixed with the inner wall of the upper mouth of the voice coil 4, and the outer edge of the lower dustproof cap 2 is respectively fixed with the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com