A motion distribution mechanism for a horizontal milling and boring machine

A technology of motion distribution and distribution mechanism, which is applied in the direction of driving devices, boring/drilling, metal processing machinery parts, etc., can solve the problems of complex structure, low transmission efficiency, lengthy transmission chain, etc., achieve simple mechanical structure and improve positioning Accuracy, the effect of improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

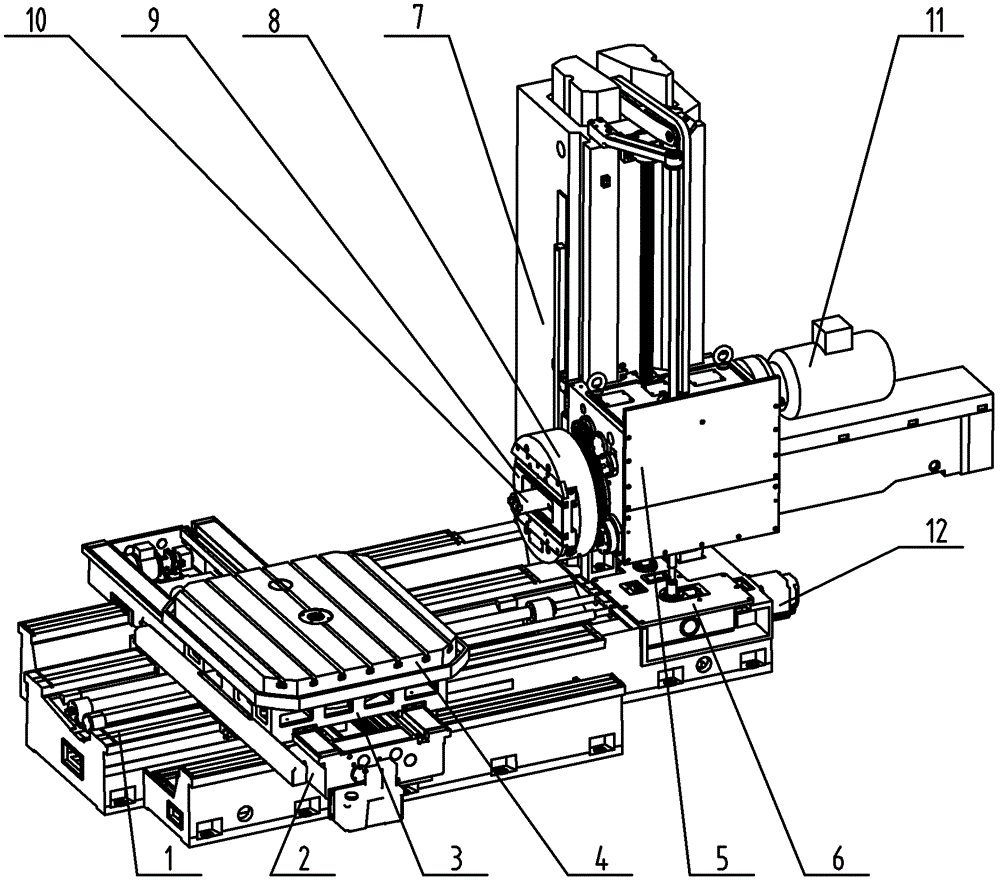

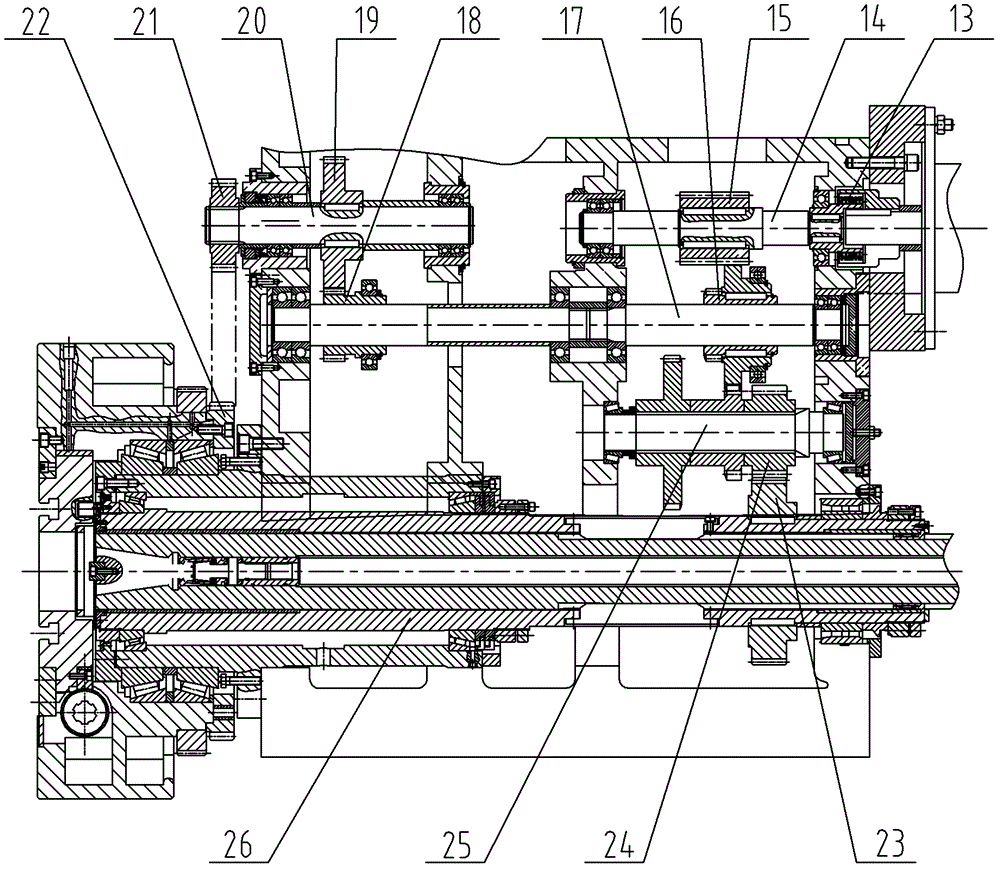

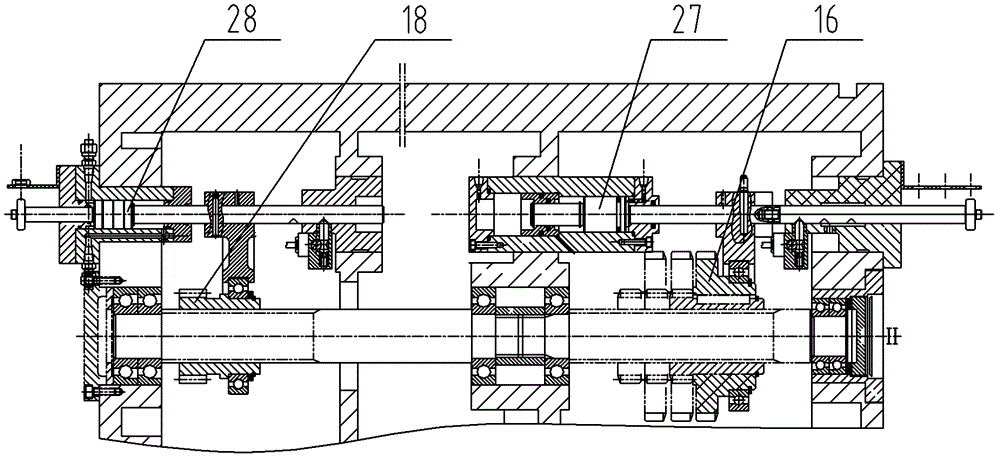

[0025] A motion distribution mechanism for a horizontal milling and boring machine (we call it "horizontal milling and boring machine AH110" or "AH110 automatic milling and boring machine"), which is a part of the horizontal milling and boring machine AH110; The machine consists of the following parts: bed 1, lower slide 2, upper slide 3, worktable 4, spindle box 5, distribution box 6, column 7, boring shaft 10, frequency conversion motor 11, servo motor 12 and electrical system ;

[0026] Among them: the lower seat 2 is arranged on the bed 1, the upper slide 3 is arranged above the lower seat 2 and the two are connected together; between the lower seat 2 and the bed 1 and between the upper slide 3 and the lower seat 2 There are connecting structures such as guide rails; the workbench 4 is arranged on the upper slide 3; the upper part of the horizontally arranged bed 1 near the end is provided with a distribution box 6 and a column 7, and the end of the distribution box 6 away...

Embodiment 2

[0036] A motion distribution mechanism for a horizontal milling and boring machine, which belongs to a part of the horizontal milling and boring machine AH110; Table 4, spindle box 5, distribution box 6, column 7, boring shaft 10, frequency conversion motor 11, servo motor 12 and electrical system;

[0037] Among them: the lower seat 2 is arranged on the bed 1, the upper slide 3 is arranged above the lower seat 2 and the two are connected together; between the lower seat 2 and the bed 1 and between the upper slide 3 and the lower seat 2 There are connecting structures such as guide rails; the workbench 4 is arranged on the upper slide 3; the upper part of the horizontally arranged bed 1 near the end is provided with a distribution box 6 and a column 7, and the end of the distribution box 6 away from the workbench 4 is provided with a Servo motor 12, vertically arranged column 7 is arranged at the near end of that end of lathe bed 1 near distribution box 6; Headstock 5 is arran...

Embodiment 3

[0044] A motion distribution mechanism for a horizontal milling and boring machine, which belongs to a part of the horizontal milling and boring machine AH110; Table 4, spindle box 5, distribution box 6, column 7, boring shaft 10, frequency conversion motor 11, servo motor 12 and electrical system;

[0045] Among them: the lower seat 2 is arranged on the bed 1, the upper slide 3 is arranged above the lower seat 2 and the two are connected together; between the lower seat 2 and the bed 1 and between the upper slide 3 and the lower seat 2 There are connecting structures such as guide rails; the workbench 4 is arranged on the upper slide 3; the upper part of the horizontally arranged bed 1 near the end is provided with a distribution box 6 and a column 7, and the end of the distribution box 6 away from the workbench 4 is provided with a Servo motor 12, vertically arranged column 7 is arranged at the near end of that end of lathe bed 1 near distribution box 6; Headstock 5 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com