Optimal shear setting method for slitting machine

A setting method and unit technology, applied in the direction of shearing device, metal processing equipment, accessories of shearing machine, etc., can solve the problems affecting the yield of strip, judgement or scrap, etc., to solve serious defect problems, The effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

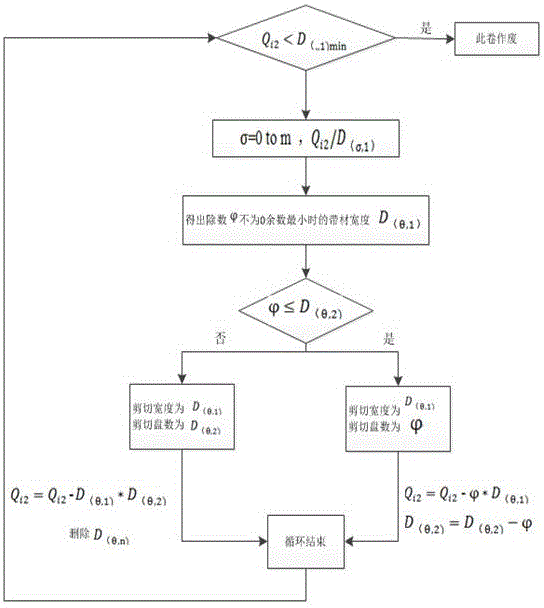

[0041] The optimal shearing setting method of the slitting unit of the present invention, the specific steps are:

[0042] 1) Collect the information of incoming materials, including: width, roll number, starting position Q of serious defects i And the width L corresponding to each defect i , the information of the incoming material is expressed in the form of an excel sheet, read from the sheet; set the width DL of the finished product to be cut out on the interface m And the number of rolls P corresponding to each width m ;

[0043] 2) It is necessary to adjust the starting position Q i and width L i , to process the data of serious defects in the material, remove the overlapped part in the width direction, and obtain a new starting position Q without overlap i2 And the width L of the corresponding defect i2 ;

[0044] According to the strip width L and defect data Q i2 and L i2 , to obtain the starting position NQ of the segmented defect-free strip j And the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com