Intelligent slitting machine electric automatic control system and method

A slitting machine, intelligent technology, applied in the direction of electrical program control, general control system, control/adjustment system, etc., can solve the problems affecting the strip yield, delamination, etc., to eliminate adverse effects, improve product quality, improve Yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

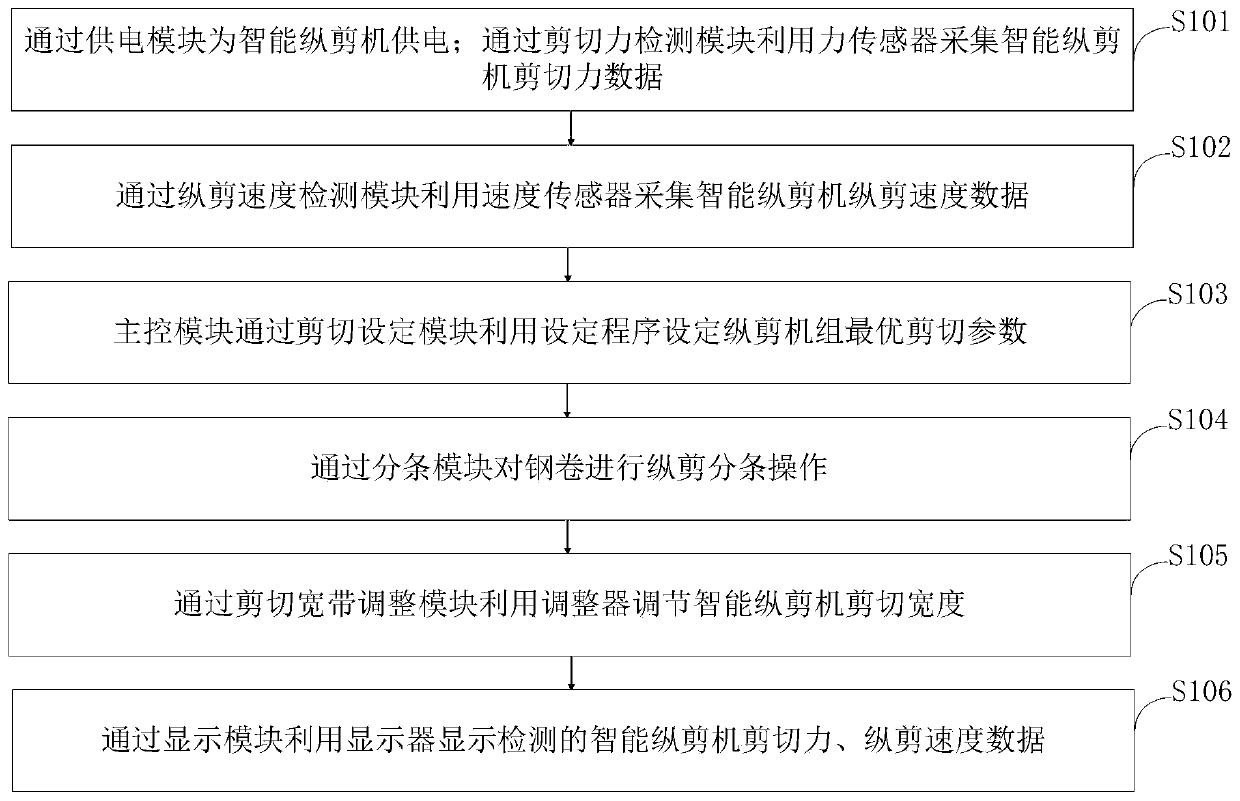

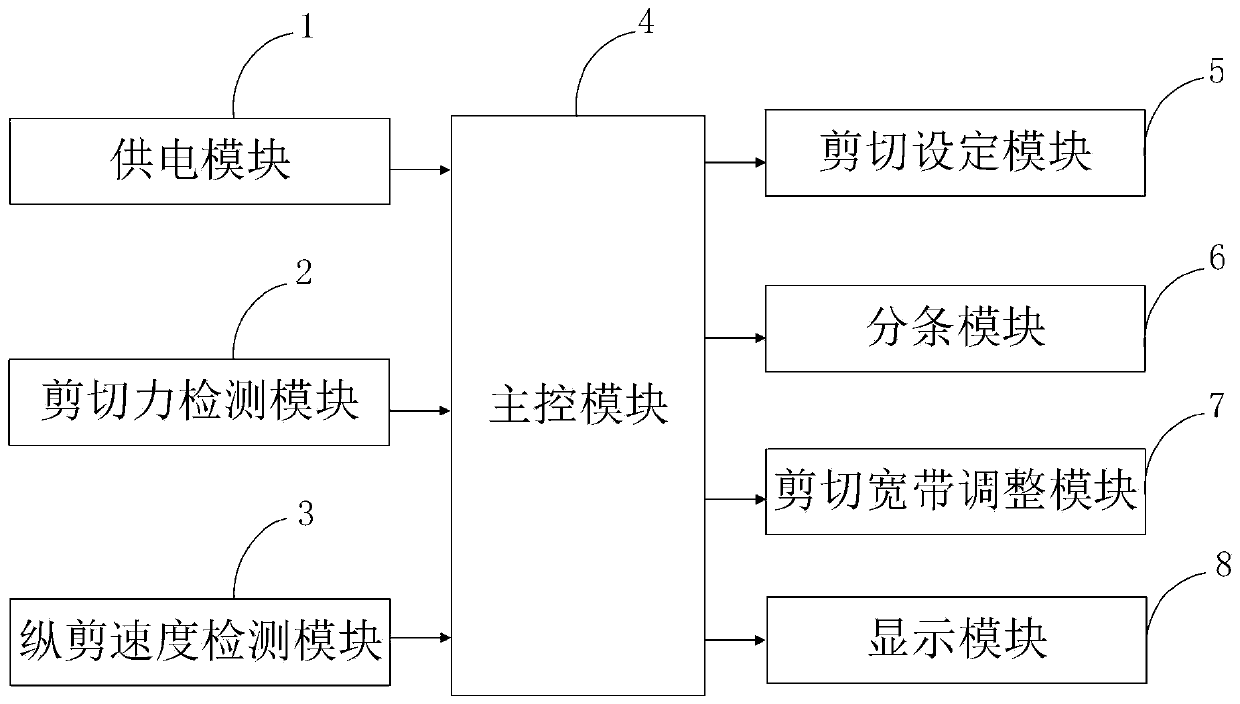

Method used

Image

Examples

Embodiment 1

[0072] The cutting setting module setting method provided by the present invention includes:

[0073] 1) Collect the information of incoming materials by setting the program, the information includes: width, roll number, starting position of serious defects and the width corresponding to each defect, and set the width of the finished product to be cut and the width of each finished product on the interface the corresponding number of rolls.

[0074] 2) Obtain the starting position of the segmented non-defective strip and the length corresponding to the starting position of each segment according to the width, the starting position and the width.

[0075] 3) According to the starting position of the segmented non-defective strip and the length corresponding to the starting position of each segment, the width of the finished product that needs to be cut out and the number of rolls corresponding to each finished product width, the algorithm is used to obtain the segmentation The...

Embodiment 2

[0079] The slitting module slitting method provided by the present invention comprises:

[0080] (1) Determine the number of strips according to the target width of the strips and the actual width of the bimetal composite plate.

[0081] (2) According to the number of slits determined in step (1), set up a knife group suitable for the number of slits on the slitting line. The knife group is composed of an upper knife and a lower knife. Adjust the upper knife or Lower the knife so that the knives at both ends of the upper knife or the lower knife are at the outermost end at the same time, and then adjust the gap between the two knives as usual.

[0082] (3) Feed the bimetallic composite material plate into the slitting line, and make the knives facing both ends of the composite material with poor elongation and high brittleness be located at the outermost upper or lower knives at the same time to ensure better elongation. Composite materials with poor and high brittleness can ...

Embodiment 3

[0085] The present invention uses the shear force detection module to collect the shear force data of the intelligent slitting machine; through the stress analysis of the intelligent slitting machine, the size of the shearing force in the shearing process is determined, and the shear force is established by using three-dimensional modeling software. The parametric model of the cutter is simplified, the finite element model of the shear is established, and a whole cycle of the shear is analyzed from entering to exit to determine the shear of the shear at each moment. Shear stress; in the establishment of the finite element model of the shear knife, three reference points A, B, and C are placed on the shear knife, and the vector formed by the three reference points satisfies

[0086] Then use the image acquisition sub-module of the shear force detection module to obtain the coordinates of M measurement display points and 3 reference points, convert the coordinates of the displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com