Method for preparing tobacco spice by tobacco fragments and application of spice

A technology for tobacco flavors and fragments, applied in the field of tobacco additives, can solve the problems of low relative content of aroma components, unsatisfactory effect of flavoring, weak purpose, etc., and achieves low cost, improved utilization rate, and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

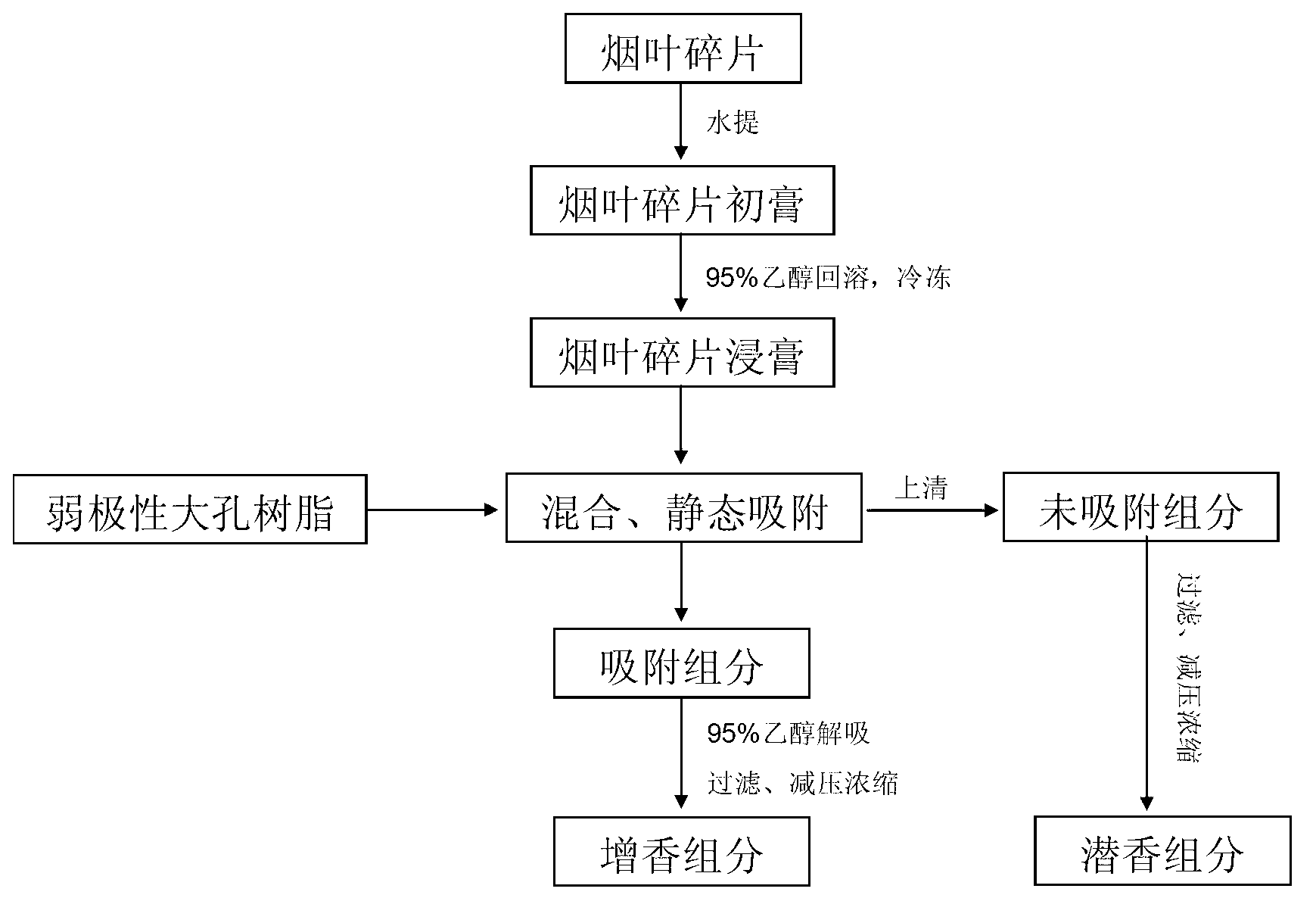

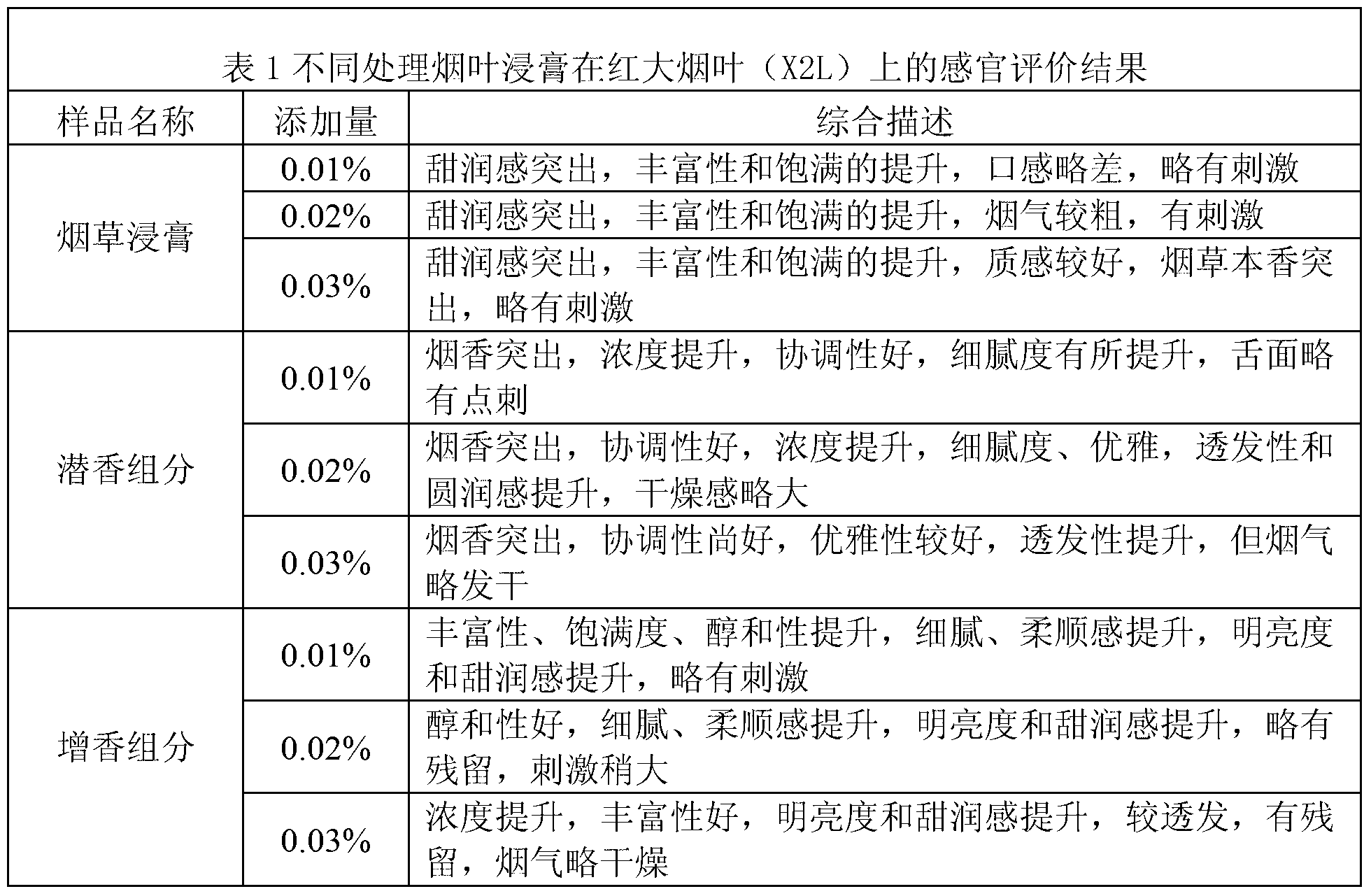

Method used

Image

Examples

Embodiment 1

[0024] (1) Weigh 500 g of pieces of Dababa leaves (C3F) into a round bottom flask, add 5 L of pure water, heat with a KMD electric heating mantle, and extract at 90 ° C for 4 hours. After the product was filtered and concentrated under reduced pressure, about 50 g of primary cream of tobacco leaf fragments was obtained. The initial paste was redissolved with 200mL of 95% alcohol solution, and was frozen at -10°C for 12 hours with sufficient stirring. After the solution was filtered, it was concentrated to a paste under reduced pressure to obtain about 40g of tobacco leaf fragment extract.

[0025] (2) Weigh 20g of tobacco leaf fragment extract, add 400mL of water, stir for 30 minutes, then add 80g of AB-8 macroporous resin, and stir for another 30 minutes. After naturally settling for 48 hours, the filtrate was filtered and concentrated under reduced pressure to a paste to obtain about 5 g of the latent aroma component of tobacco fragments.

[0026] (3) Desorb the macroporous...

Embodiment 2

[0029] (1) Weigh 1,000 g of pieces of tabacco leaves (C3F) into a round bottom flask, add 15 L of pure water, heat with a KMD electric heating mantle, and extract at 80°C for 6 hours. After the product was filtered and concentrated under reduced pressure, about 102 g of the primary cream of tobacco leaf fragments was obtained. The initial paste was redissolved with 600mL of 95% alcohol solution, and frozen at -10°C for 12 hours with sufficient stirring. After the solution was filtered, it was concentrated under reduced pressure to a paste, and about 86.7g of tobacco leaf fragment extract was obtained.

[0030] (2) Weigh 40g of tobacco leaf fragment extract, add 1L of pure water, stir for 30 minutes, add 200g of HPD-100 macroporous resin, and stir for another 30 minutes. After natural sedimentation for 72 hours, the filtrate was filtered, concentrated under reduced pressure to a paste, and about 12 g of latent aroma components of tobacco fragments were obtained.

[0031] (3) T...

Embodiment 3

[0034] (1) Weigh 2,000 g of the fragments of tabacco leaves (C3F) into a round-bottomed flask, add 24 L of pure water, heat with a KMD electric heating mantle, and extract at 85°C for 5 hours. After the product was filtered and concentrated under reduced pressure, about 210 g of tobacco leaf debris primary cream was obtained. The initial paste was redissolved with 1L of 95% alcohol solution, and was frozen at 10°C for 12 hours under full stirring. After the solution was filtered, it was concentrated under reduced pressure to a paste, and about 157g of tobacco leaf fragment extract was obtained.

[0035] (2) Weigh 100g of tobacco leaf fragment extract, add 2.3L of pure water, stir for 30 minutes, add 450g of AB-8 macroporous resin, and stir for another 30 minutes. After naturally settling for 60 hours, the filtrate was filtered and concentrated under reduced pressure to a paste to obtain about 30 g of the latent aroma component of tobacco fragments.

[0036] (3) The macroporou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com