Buffing brushing machine

A technology of brushing machine and skin grinding, which is applied in the direction of mechanical treatment of leather surface, small raw hide/big raw hide/leather/fur mechanical treatment, raw hide/leather/fur manufacturing equipment, etc. It can solve the problem of poor dust removal effect, inconvenient operation, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

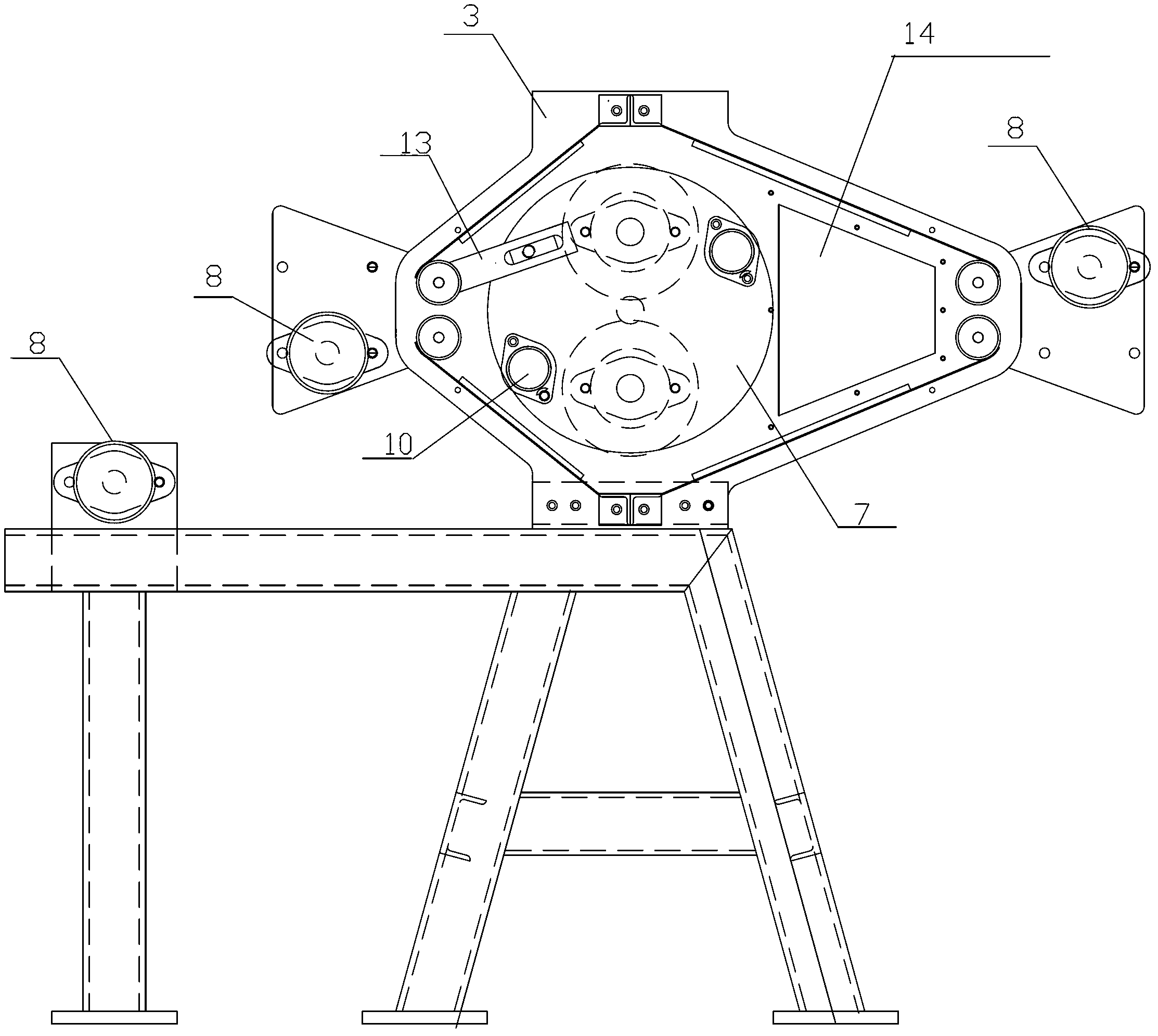

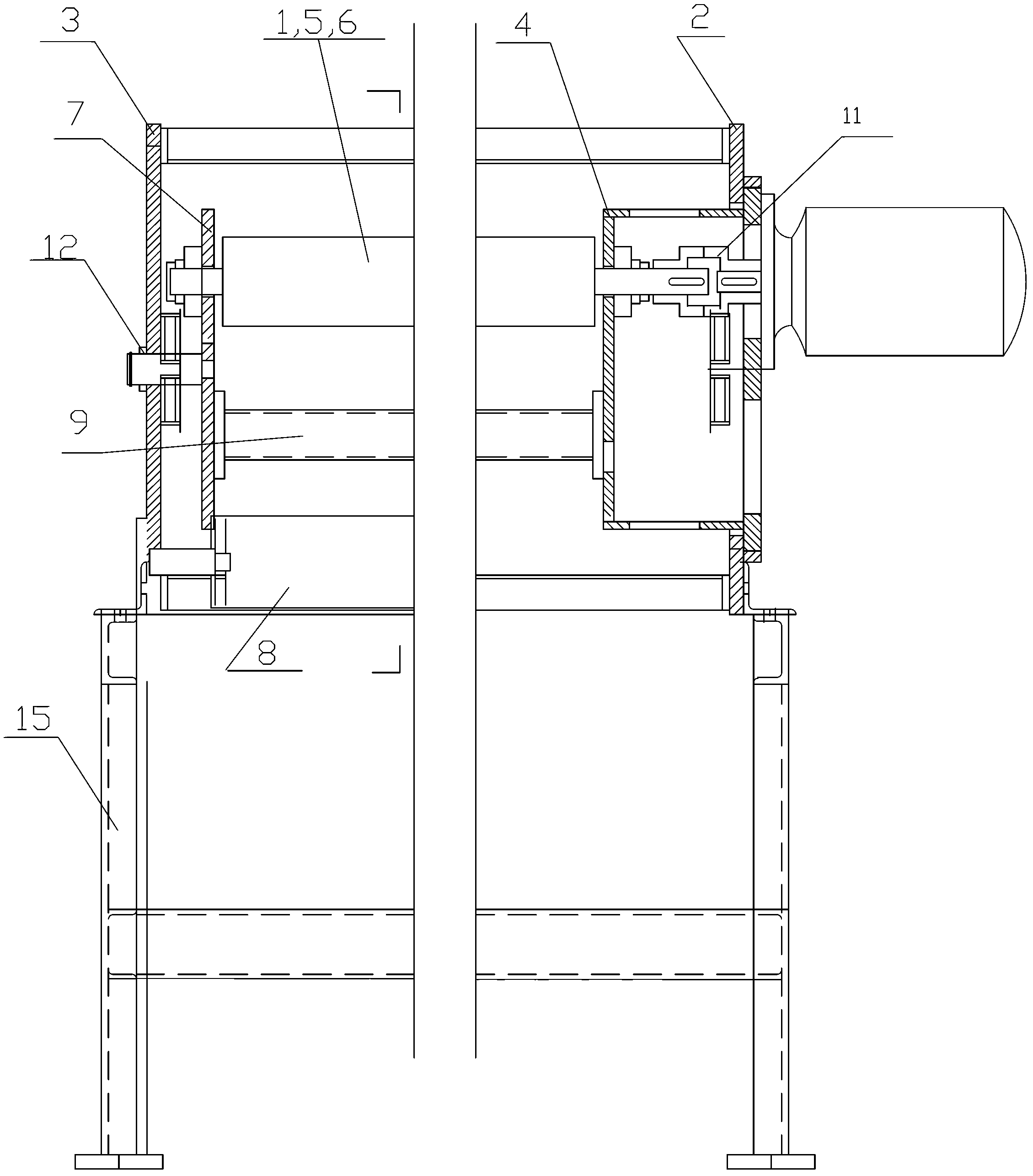

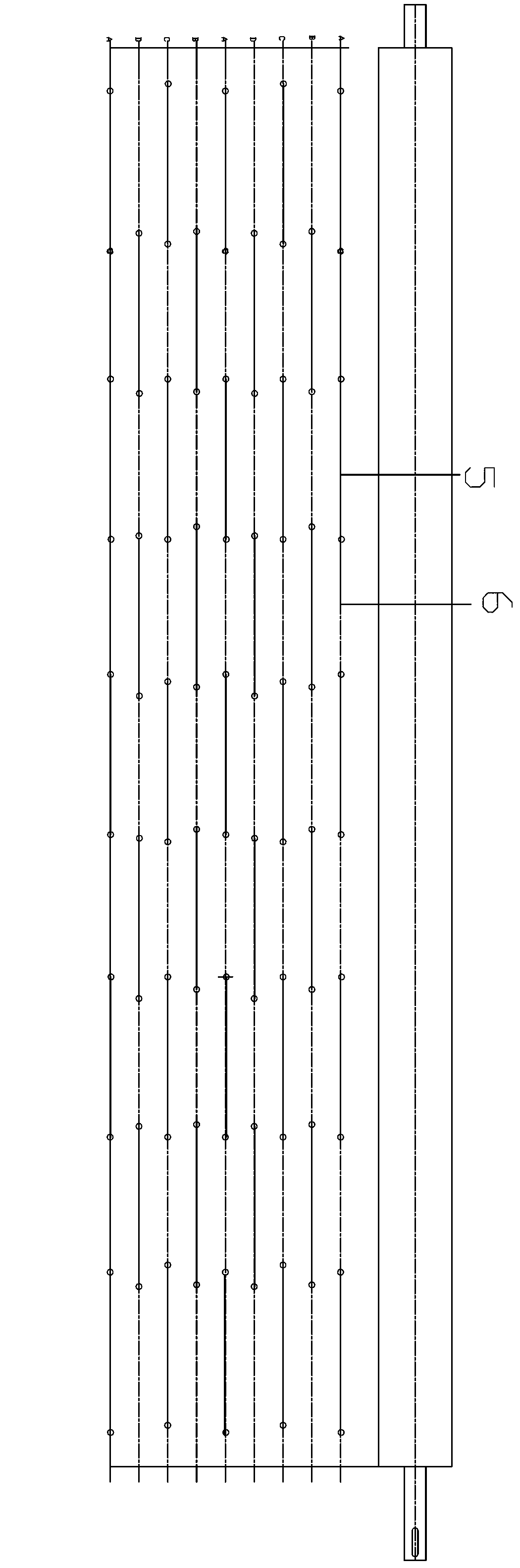

[0014] Such as figure 1 , figure 2 As shown, the dermabrasion and brushing machine includes a frame 15 and a transmission part. One ends of two brush rollers 1, 9 are respectively connected to the motor fixed disk 4, and the motor is connected through a coupling 11, and the motor fixed disk is movable and fixed On the left wall plate 2 of the frame, the other ends of the two brush rollers are fixed on the support base 7, and the support base is movably connected to the right wall plate 3 of the frame; there are two inner plates between the motor fixing plate and the support base. The connecting pipe 10 is connected. Such as image 3 , The brush 5 and the flapper 6 are arranged at intervals on the cylinder surface of the bristle roller. Such as Figure 4 , Figure 5 , The cross section of the flapping board 6 is a convex wave crest shape. Such as Image 6 , The brush structure is that the fixed plate is provided with bristles. The left wall panel of the rack is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com