Spinning frame automatic doffing trolley

A technology of automatic doffing and doffing trolley, which is applied in the direction of textiles and papermaking, and can solve the problems of destroying yarn quality indicators and affecting the accuracy of spindle bearings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

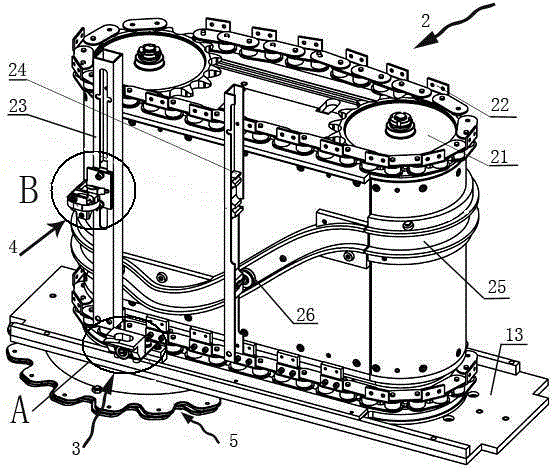

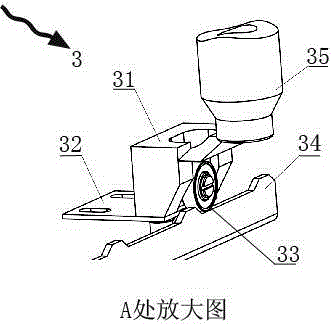

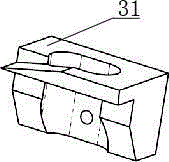

[0028] Example: such as figure 1 , 2 , 8, a dolly for automatic doffing of a spinning frame, comprising a doffing dolly 1 and an automatic doffing device 2, an automatic doffing device 2 is arranged on a bottom plate 13 above the doffing dolly 1, and the doffing device 2 The pre-loose mechanism 3 on the top is installed on the bottom plate 13 of the doffing trolley 1 through the spring steel plate 32. The spring steel plate 32 is fixed with a pre-loose block 31. When the doffing trolley 1 advances, the pre-loose block 31 advances with the trolley and is inserted into the full bobbin. 35 lower ends, make full bobbin 35 lower ends rise along the slope of pre-loose block 31 (as image 3 shown), the rising distance is the distance from the ingot disc to the ingot hook; at this time, the bearing 33 located under the slope of the pre-loosening block 31 drives the pre-loosening block 31 to be at the protrusion of the flat cam 34, and then the pre-loosening block 31 is on the plane c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com