Textile flyings cleaner

A cleaner and flying flower technology, which is applied in textiles and papermaking, can solve the problems that the flying flowers on the traveler cannot be cleaned, and achieve the effects of improving service life, avoiding yarn breakage, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

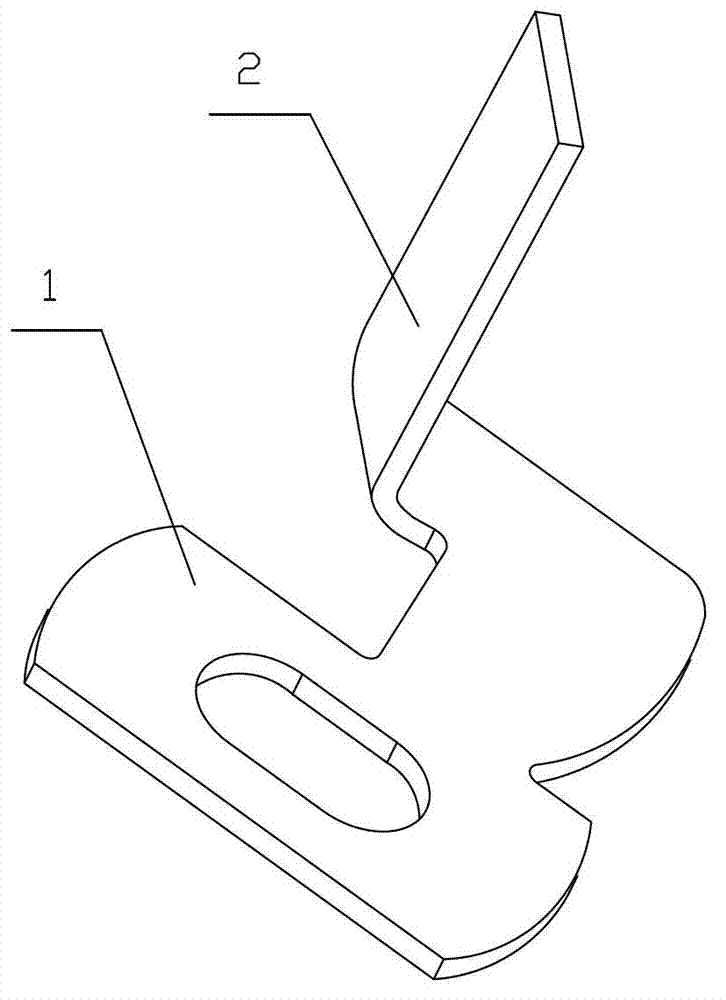

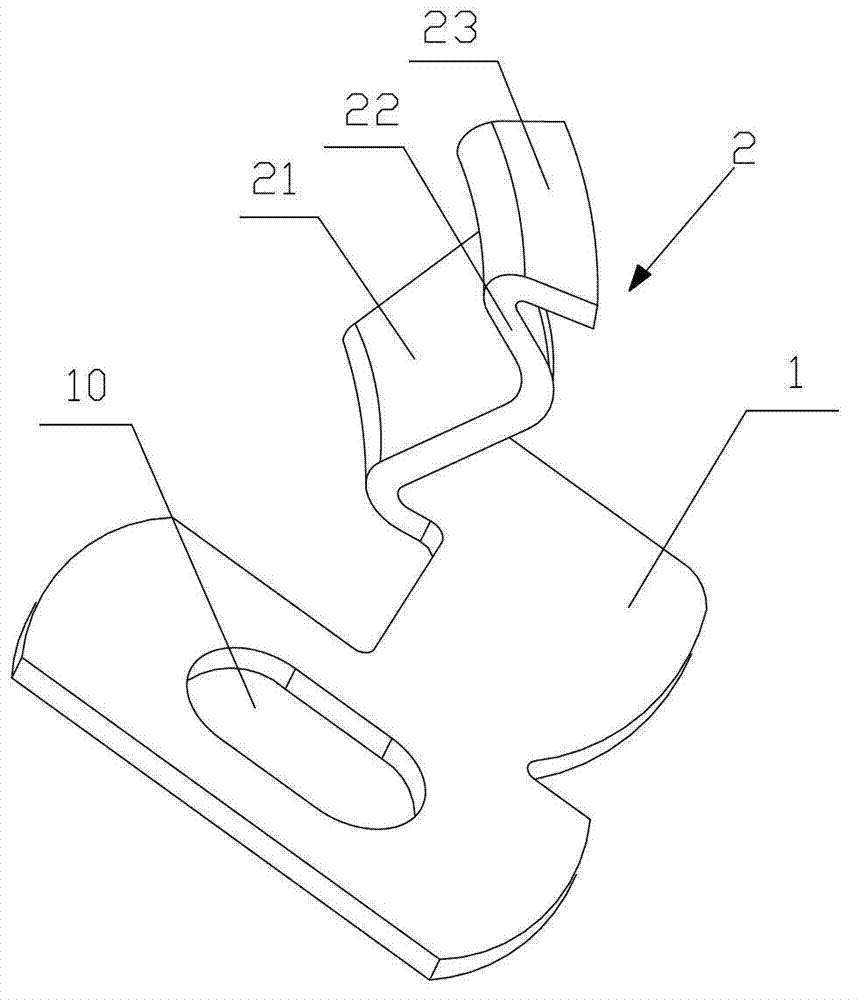

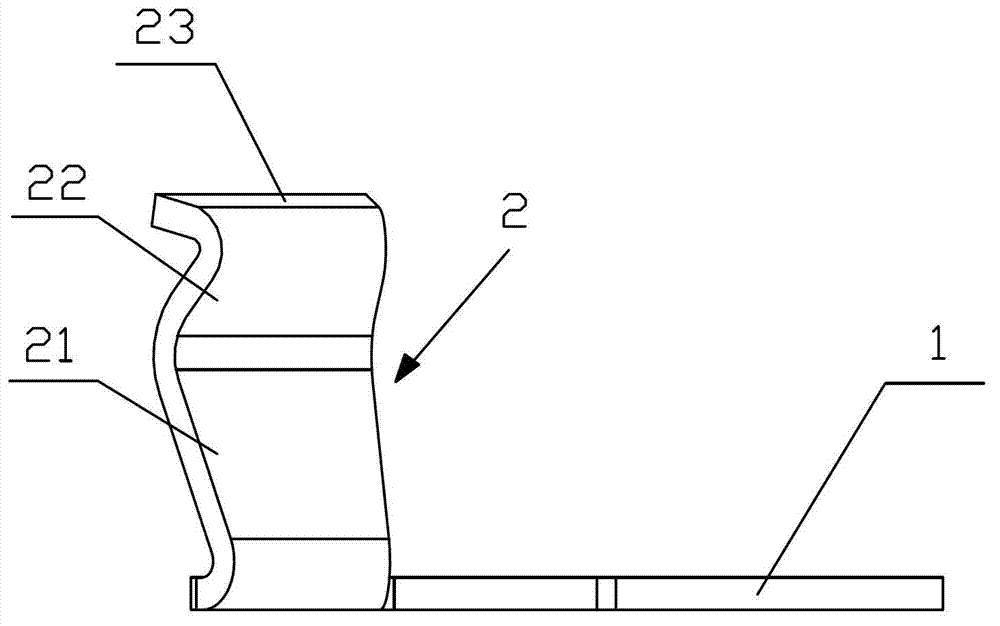

[0023] like figure 2 and image 3 as shown, figure 2 It is a perspective view of a textile fly cleaner proposed by the present invention, image 3 for figure 2 main view.

[0024] refer to figure 2 and image 3 , a textile fly cleaner proposed by the present invention, comprising a bottom plate 1 and a cleaning plate 2 extending upward from the bottom plate 1, and a mounting hole 10 is provided on the bottom plate 1; the cleaning plate 2 is bent laterally at a predetermined angle to form a first cleaning plate 21 and a second cleaning plate 22.

[0025] During the working process, the traveler is placed on the upper part of the steel ring, the base plate 1 is pressed against the lower part of the steel ring, and the traveler is close to the inside of the bending of the first cleaning plate 21 and the second cleaning plate 22. When the traveler is running at high speed, the An airflow is generated between the first cleaning plate 21 and the second cleaning plate 22, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com