Manufacturing method and processing device for low-temperature water-soluble polyvinyl alcohol non-woven fabric

A water-soluble polyvinyl alcohol, nonwoven technology, applied in nonwovens, complete sets of equipment for producing artificial threads, textiles and papermaking, etc., can solve the problems of difficult transportation, easy gelation, and difficult cutting, and avoid phase Separation, low cost, effect of suppressing air bubbles

Active Publication Date: 2017-07-14

大连天马可溶制品有限公司

View PDF10 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to solve the problems in the prior art that polyvinyl alcohol nonwovens are easy to gel when exposed to water, difficult to cut, and difficult to transport, a preparation method and processing equipment for low-temperature water-soluble polyvinyl alcohol nonwovens are provided

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

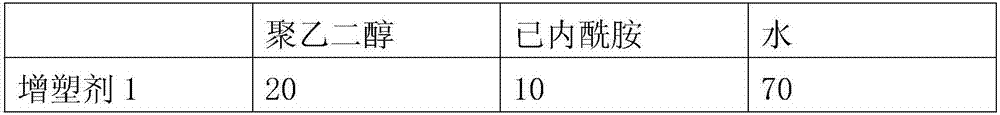

Embodiment 1

[0024] Wash and swell polyvinyl alcohol with specifications 0388, 0588, and 1788 with 2 times the mass of ice water for 2 hours.

Embodiment 2

[0026] Wash and swell polyvinyl alcohol with specifications 0388, 0588, and 1788 with 3 times the mass of ice water for 2 hours.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

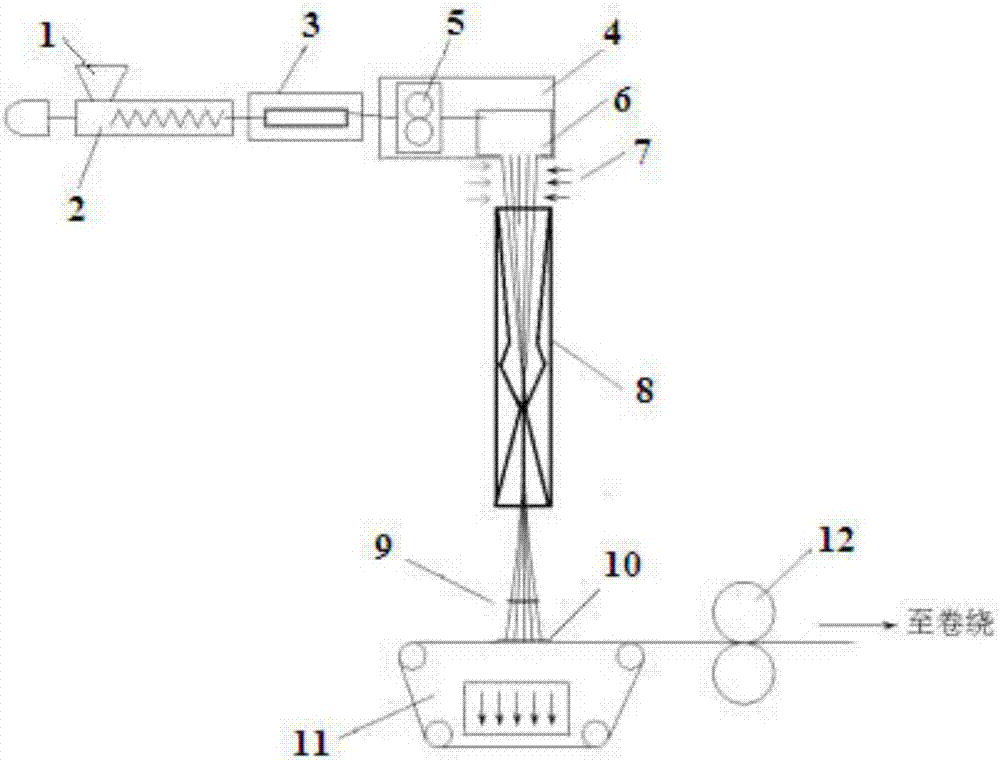

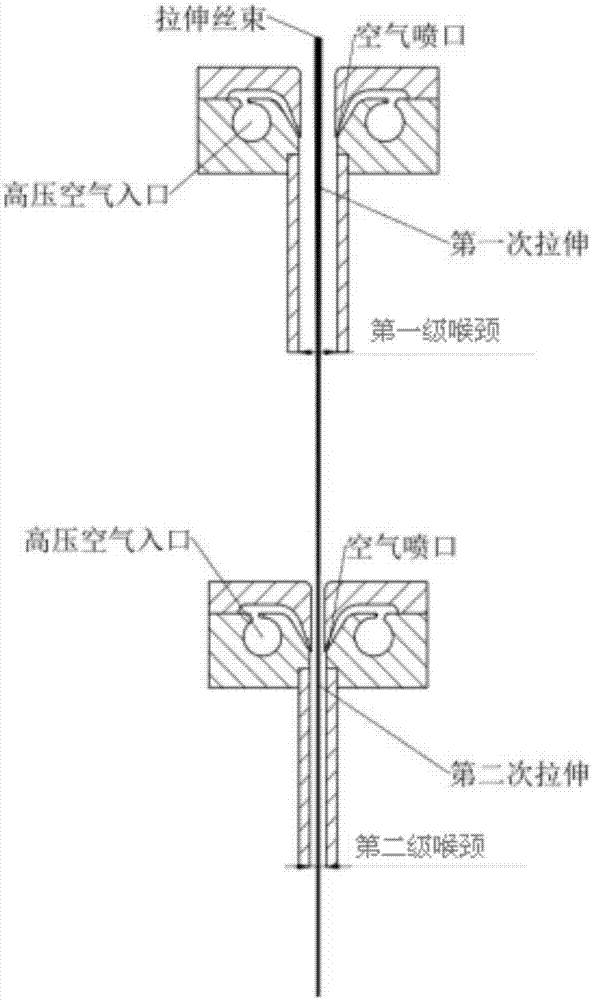

The invention relates to the field of polyvinyl alcohol non-woven fabric, and especially relates to a manufacturing method and a processing device for a low-temperature water-soluble polyvinyl alcohol non-woven fabric. The device comprises a feeding opening, a screw extruder, a melt filter, a spinning manifold, a combined stretching slit, a silk reciprocator, an air suction device, and a reinforcing device. Through water plasticized melt-spinning, the fabric is directly formed, a manufacturing process of the polyvinyl alcohol non-woven fabric is greatly shortened, cost is reduced, and environmental pollution is reduced. The combination of the process and the device preferably solves a technical problem of low-temperature water-soluble polyvinyl alcohol non-woven fabric, and a polyvinyl alcohol non-woven fabric product whose water solution temperature is 20-40 DEG C is successfully manufactured. The method and the device are simple in process and low in cost, and are suitable for industrial production.

Description

technical field [0001] The invention relates to the field of polyvinyl alcohol nonwoven fabrics, in particular to a preparation method and processing equipment for low-temperature water-soluble polyvinyl alcohol nonwoven fabrics. Background technique [0002] Polyvinyl alcohol fiber is currently the only water-soluble synthetic fiber that can be produced on a large scale in the world. Its non-woven products have a wide range of applications in medical and health care, embroidery, clothing and other fields. Generally, polyvinyl alcohol nonwoven fabrics are made of polyvinyl alcohol short fibers as raw materials, and are manufactured through carding, web forming, and reinforcement. Polyvinyl alcohol short fibers are also mostly obtained by wet spinning. Therefore, the traditional polyvinyl alcohol nonwoven technology has complex processing and high cost; the preparation process of polyvinyl alcohol fibers is complicated and polluted; the product has a high melting point and i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D04H3/007D01D13/00D01D1/09D01D10/02

CPCD01D1/09D01D10/02D01D13/00D04H3/007D10B2321/06

Inventor 郭静刘闻徐德增刘建为

Owner 大连天马可溶制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com