Photocatalyst discharge method for producing color patterns on topping textile

一种纺织品、光触媒的技术,应用在纺织染整领域,能够解决影响产品因素多、消耗大水和能源、条件不易控制等问题,达到省去药品及废液排放、易于控制、pH值适应范围广的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

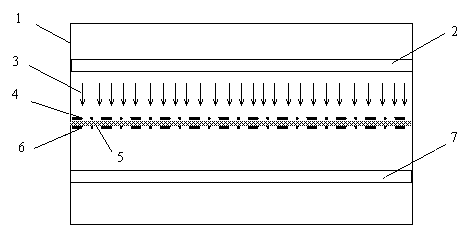

[0028] The present embodiment provides a kind of photocatalyst color drawing method that produces color pattern on textile, comprises the following steps:

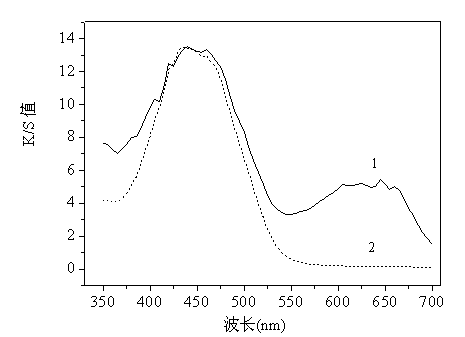

[0029] 1. Use the selected color dyes to dye the textiles according to the conventional dyeing method. In this example, the textiles are cotton fabrics (8cm×20cm), and the processing conditions for the dyeing of the conventional color dyes are: 2.5% ( o.m.f.) Vat Golden RK Dye, 20.0g L -1 Sodium chloride, 7.5 g L -1 Caustic soda, 10.0 g L -1 Hydrosulfite, 0.2 g L -1 Taikoo oil, bath ratio 1:50; reduced golden RK dye is reduced by dry cylinder method, put the weighed dye in a beaker, add a few drops of Taikoo oil to make a slurry, dilute with a small amount of deionized water, add 2 / 3 A small amount of caustic soda, sodium hydrosulfite, and water are added to make the dye bath 1 / 4 of the total amount of the dye solution. Stir and heat up to 50°C. The reduction treatment is 10-15 minutes, and then add 3 / 4 of the total amo...

Embodiment 2

[0047] This embodiment provides a photocatalyst color extraction method for producing colored patterns on textiles, and other steps of the method are the same as in Embodiment 1. Among them, the ground color dyeing dye in step 2 is 0.5% (o.m.f.) direct purplish red GB dye; in step 3, the dyeing cotton fabric is treated for 35 minutes, and the ambient temperature is 60°C.

Embodiment 3

[0049] This embodiment provides a photocatalyst color extraction method for producing colored patterns on textiles, and other steps of the method are the same as in Embodiment 1. Wherein in step 1, the base color dyeing dye is 0.5% (o.m.f.) vat golden RK dye; in step 2, the ground color over-dyeing dye is 0.5% (o.m.f.) direct light-fast turquoise blue GB dye; in step 3, the over-dyeing cotton fabric The treatment was carried out for 60 minutes, and the ambient temperature was 30°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com