Framework swinging alternating type paper pulp molding machine

A pulp molding and forming machine technology, applied in the direction of textiles and papermaking, can solve the problems of long processing cycle, low degree of automation, large investment, etc., and achieve the effect of high production efficiency, high degree of automation and simplified production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

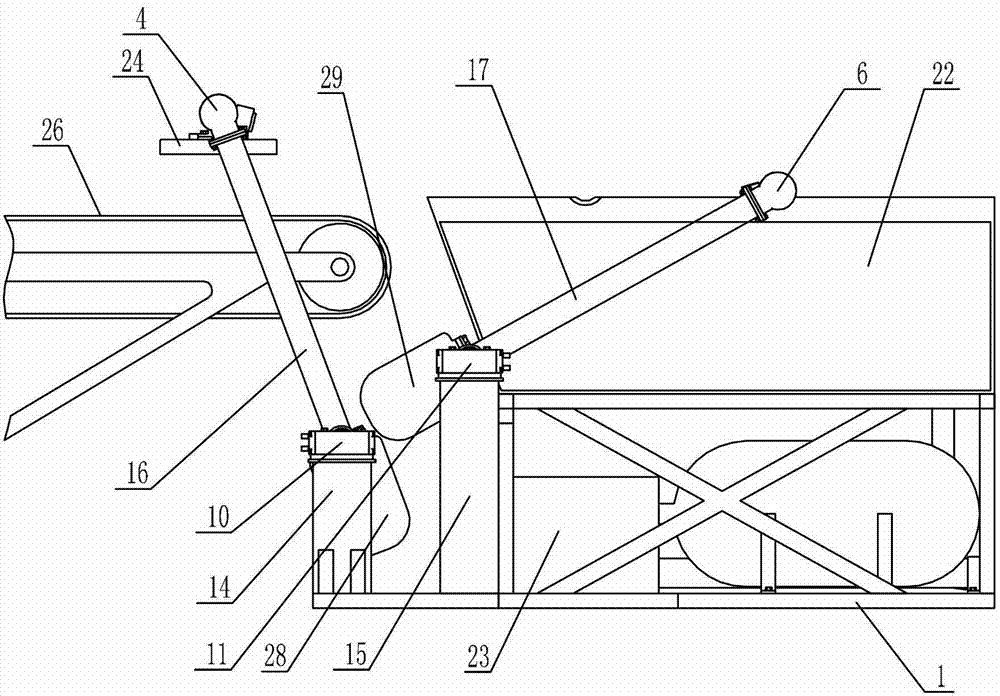

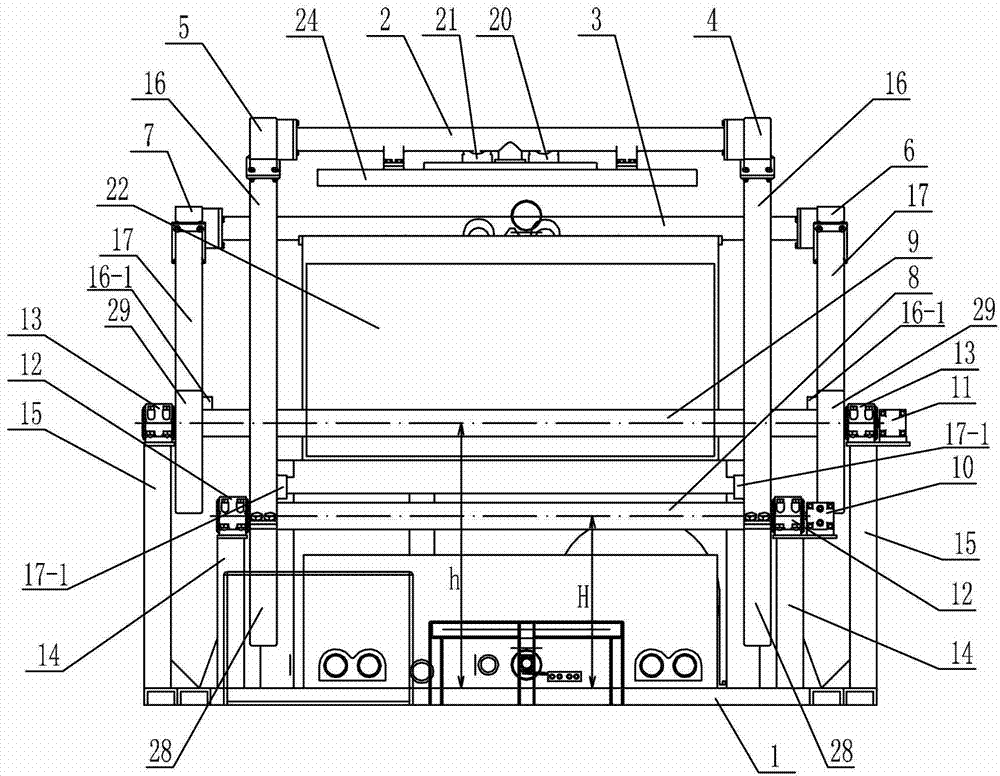

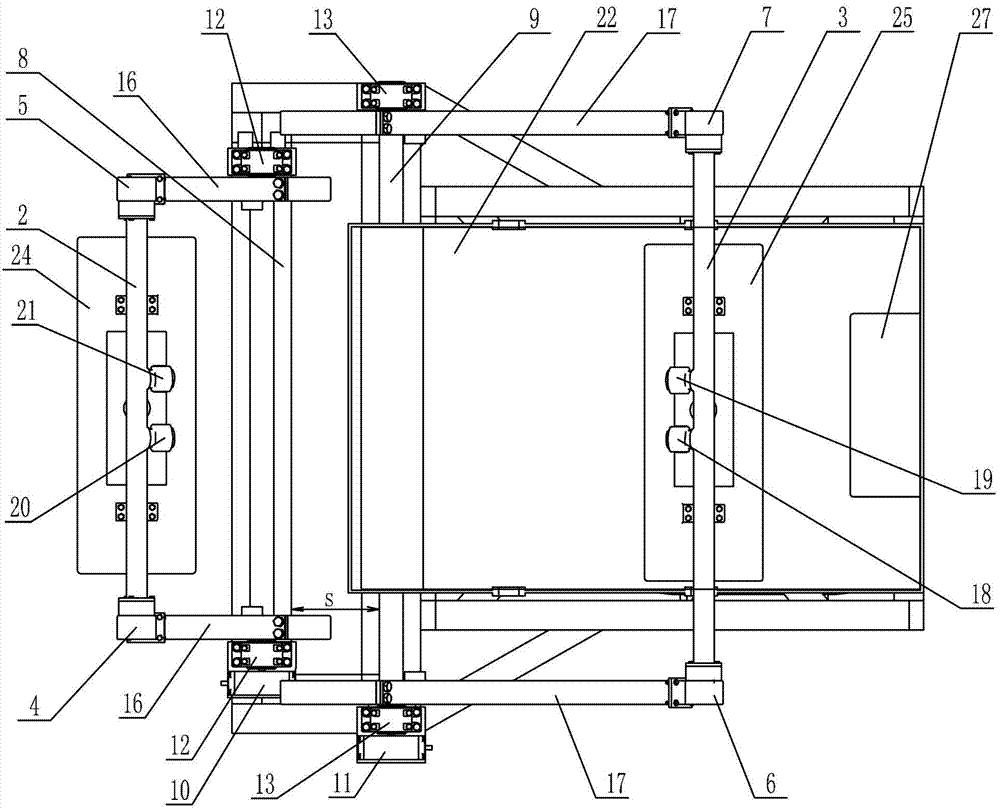

[0013] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, this embodiment includes a frame 1, a front pipeline 2, a rear pipeline 3, a front vacuum head 4, a front compressed air head 5, a rear vacuum head 6, a rear compressed air head 7, a front spindle 8, Rear main shaft 9, front driving device 10, rear driving device 11, two front bearing blocks 12, two rear bearing blocks 13, two first fixed supports 14, two second fixed supports 15, two front swings Arm 16, two rear swing arms 17, rear pipeline vacuum control valve 18, rear pipeline compressed air control valve 19, front pipeline vacuum control valve 20, front pipeline compressed air control valve 21, pulp tank 22, automatic control box 23, front The mold box 24 and the rear mold box 25, the front pipeline 2 and the rear pipeline 3 are arranged in parallel, the front vacuum head 4 and the front compressed air head 5 are respectively installed at the two ends of the front pipeline 2, t...

specific Embodiment approach 2

[0015] Specific implementation mode two: combination Figure 1 ~ Figure 3To describe this embodiment, the front swing arm 16 and the rear swing arm 17 of this embodiment are both provided with hollow cavities. Allows for easy airflow. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation mode three: combination figure 2 Describe this embodiment, the height h of the front spindle between the front spindle 8 and the bottom surface of the frame 1 of this embodiment is smaller than the rear spindle height H between the rear spindle 9 and the bottom surface of the frame 1, and the horizontal distance between the front spindle 8 and the rear spindle 9 is S, the length of the front swing arm 16 is equal to the length of the rear swing arm 17. Among them, h, H, and S are obtained by calculation, so that the front mold box 24 and the rear mold box 25 reach the same position above the conveyor belt 26 to ensure uniform feeding. The front mold box 24 and the rear mold box 25 are designed to have a height difference, so that the front mold box 24 and the rear mold box 25 do not interfere with each other. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com