Adjusting nut for adjusting motorcycle valve clearance

A valve clearance and adjusting nut technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of inability to guarantee one-time adjustment, long time spent, poor accuracy, etc., and achieve ingenious design, easy implementation, and precision Adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

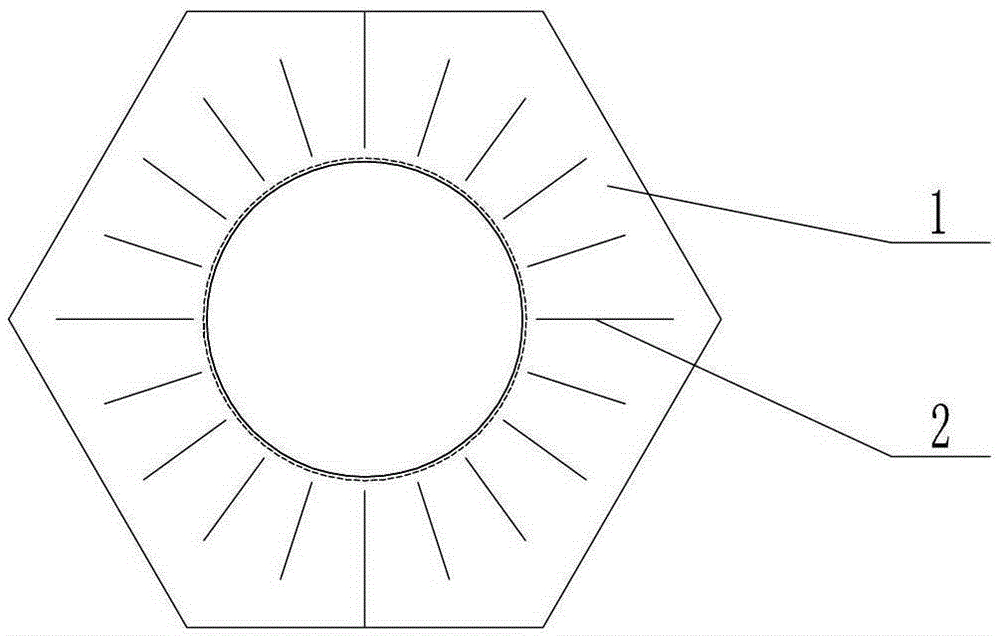

[0016] see figure 1 , the present invention has a nut body 1, the outer contour of the threaded body 1 is a regular hexagon, with a screw hole in the center. On the end surface of at least one end of the nut body 1, there are equisectors 2 uniformly distributed on the circumference. Relatively symmetrical. The center of the circle surrounded by the bisectors 2 on the same end surface is on the axis of the nut body 1 , and the extension lines of each bisector 2 intersect the axis of the nut body 1 . The number of bisectors 2 on the same end face is 10-30, and in this embodiment, it is preferably 20. The bisector 2 can be a shallow groove formed on the end surface of the nut body 1, and the width of the shallow groove is preferably 0.1 mm; the bisector 2 can also be a scratch or a drawn line.

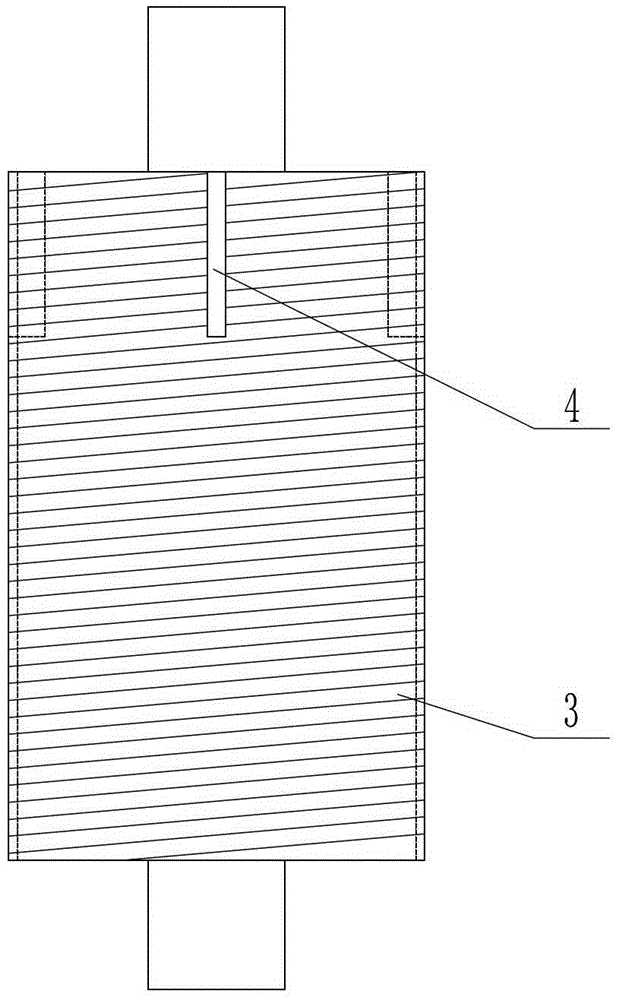

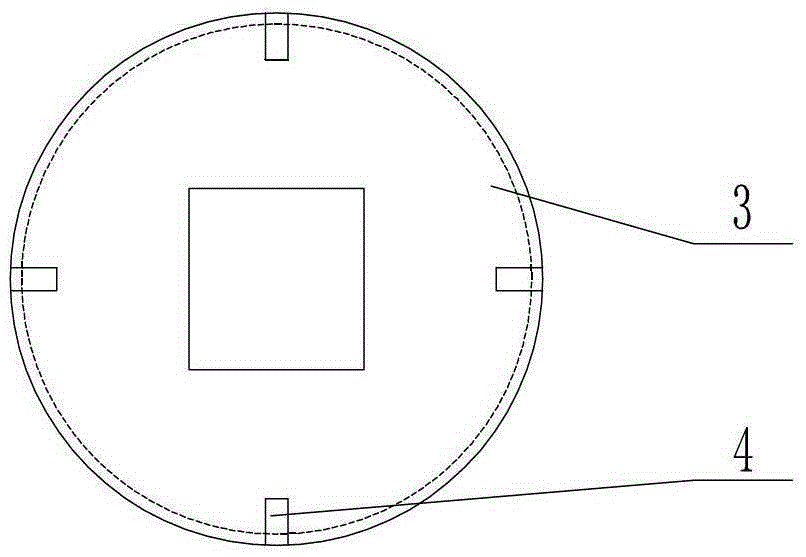

[0017] Such as figure 2 , image 3 As shown, the adjusting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com