Impeller and centrifugal compressor including the impeller

An impeller and blade technology, applied in the field of centrifugal compressors, can solve problems such as impeller efficiency cannot be further improved, separation loss, etc., and achieve the effects of widening the scope of high-efficiency area, reducing surge flow, and improving impeller efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

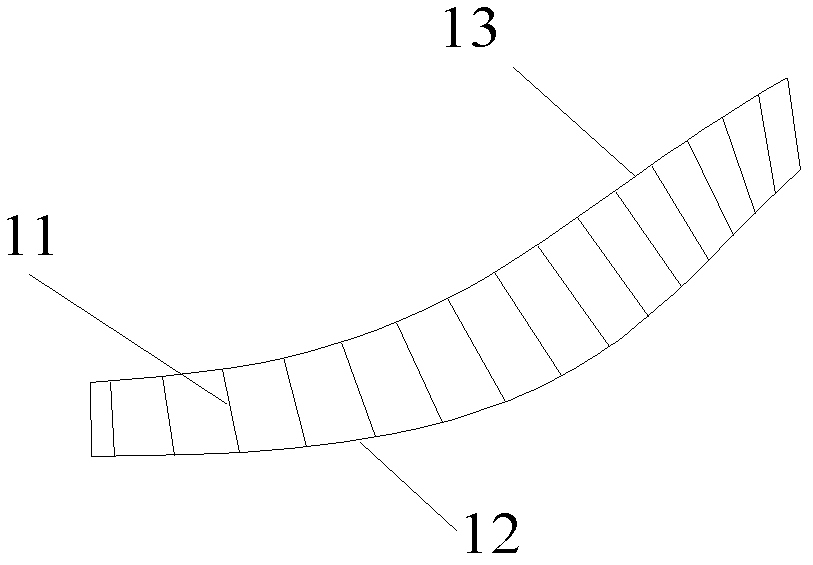

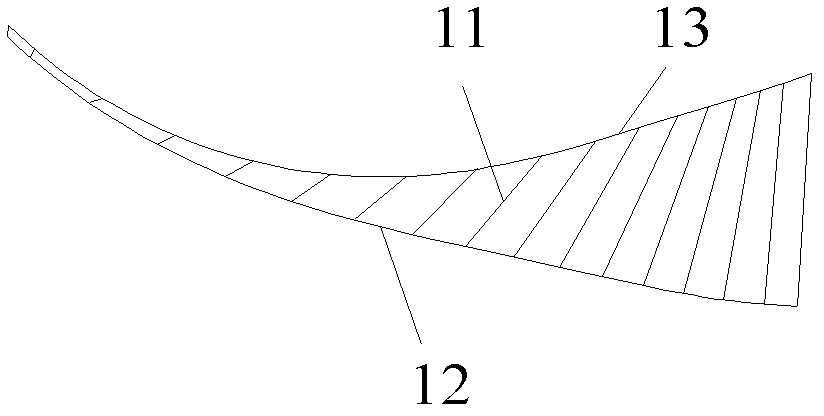

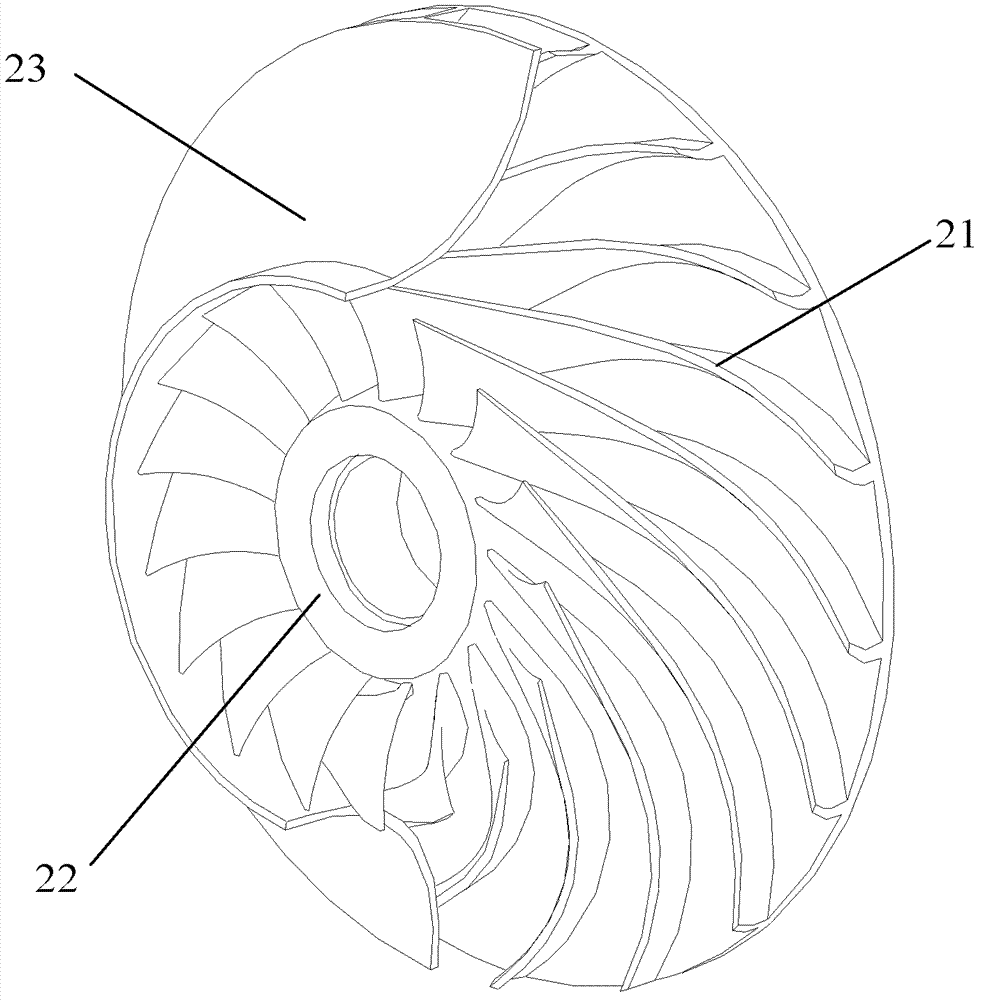

[0029] like figure 2 and image 3 As shown, the impeller provided by the present invention includes: a blade 21 and a hub 22 connected to one side of the blade 21, wherein the surface of the blade 21 is a blade curved surface with a control line 211 (such as Figure 4 As shown), the control lines 211 are combined to form the curved surface of the blade, wherein the control lines 211 are curved lines. Preferably, the present invention also includes a wheel cover 23 near the other side of the blade 21 .

[0030] When the present invention is in use, the structure of the hub 22 completes the function of transmitting torque from the rotating shaft to the impeller. Under the action of the torque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com