Lifting plan process file format for full-automatic shuttle sample looms

A process file, fully automatic technology, applied in special data processing applications, instruments, electrical digital data processing and other directions, can solve the problems of slow reading and writing, easy modification of files, consumption of CPU resources, etc. The effect of reading and processing, ensuring correctness and integrity, and avoiding scratches on cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

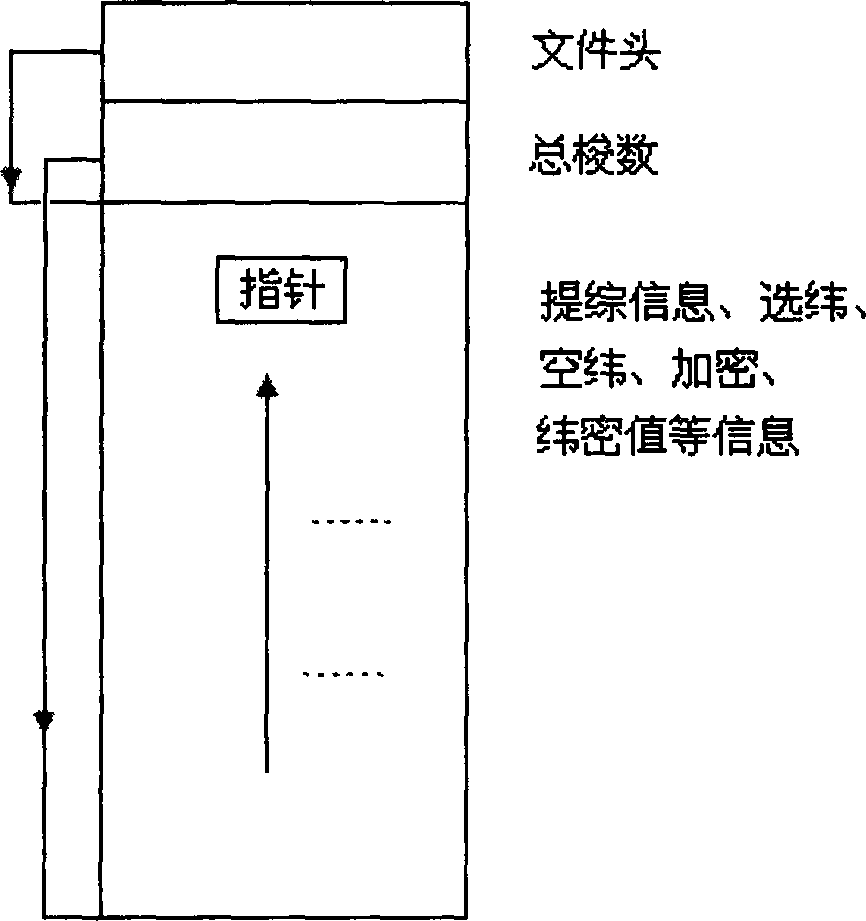

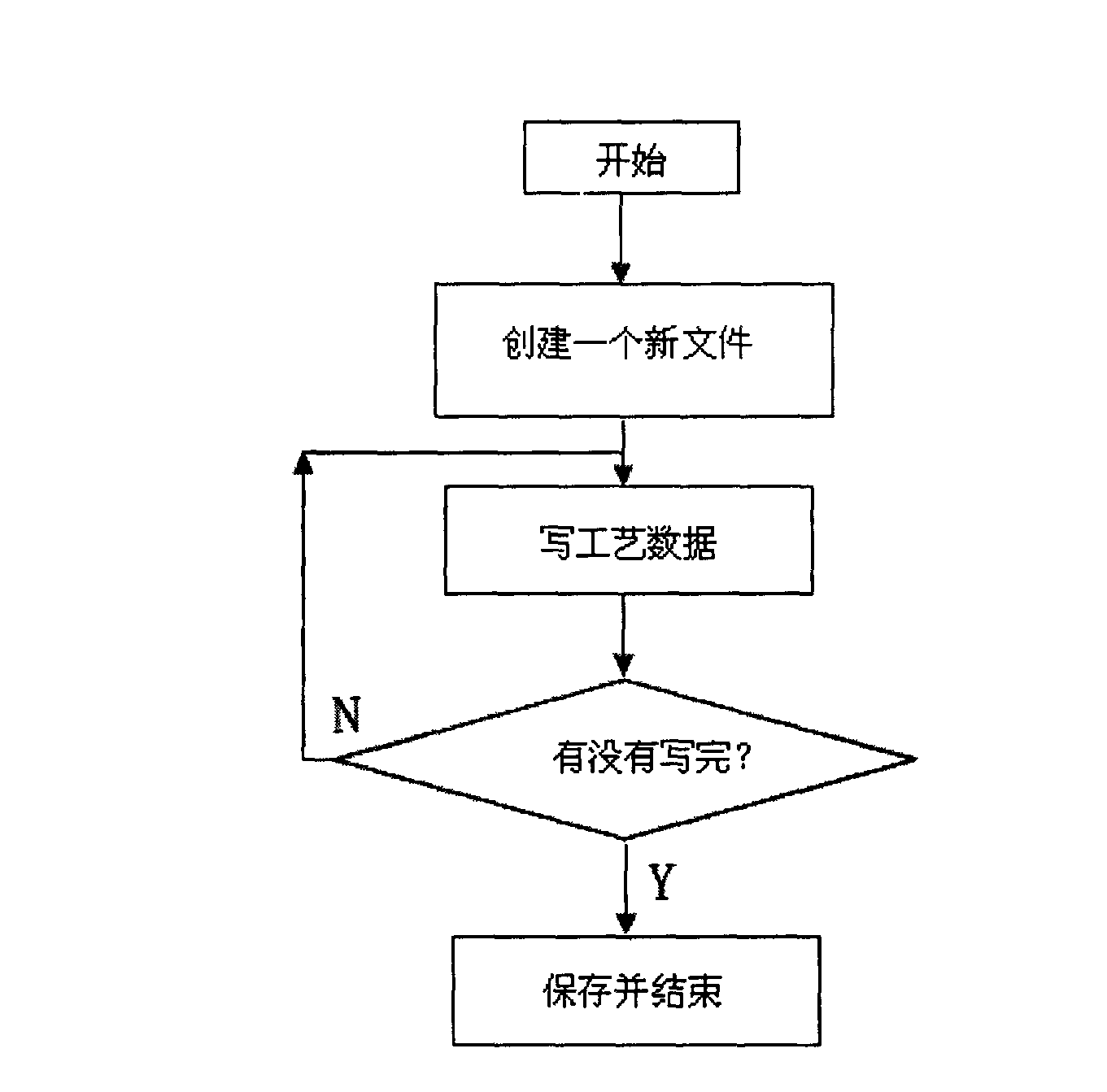

[0015] The process of creating and writing the cardboard process file:

[0016] 1. Read the process parameters into the memory, call the interface function File::Create and select the relevant File.Open() with parameters to create a new cardboard process file.

[0017] 2. Use the interface function File.Write() function with parameters to press figure 2 data input.

[0018] 3. Close the file.

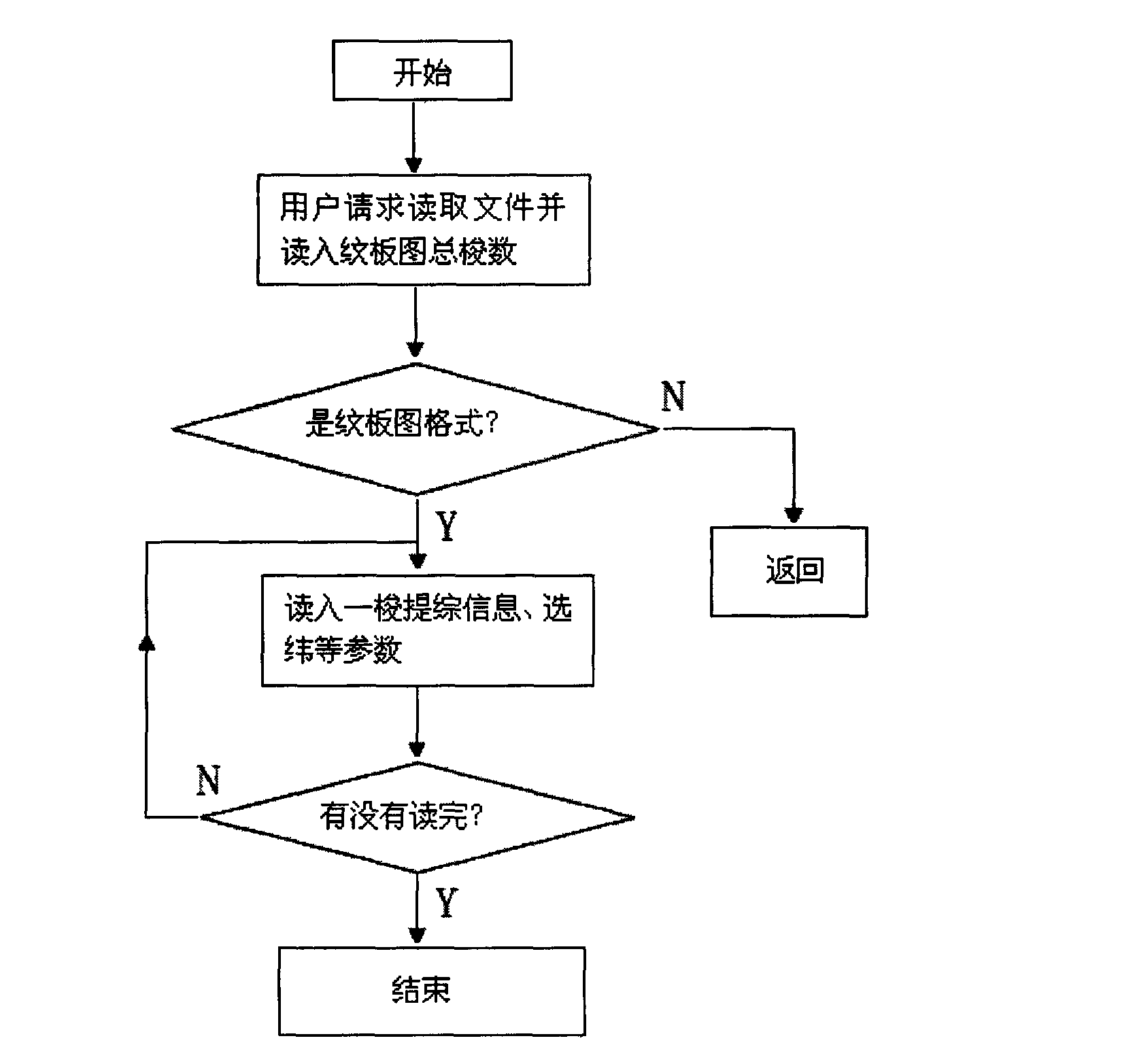

[0019] The process of opening the cardboard process file:

[0020] 1. Execute the interface function File.Open() with parameters to open the cardboard process file.

[0021] 2. Use the interface function File.Read() with parameters to press image 3 Read the content of the file, and judge whether the file format is correct, and read the process parameters into the memory unit for weaving.

[0022] 3. Close the file.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com