SOA-architecture-based method for device data collecting and monitoring early warning

A technology of equipment data and data, applied in the field of modeling based on visual graphics, can solve problems such as difficult to guarantee, difficult to guarantee product quality, and untimely discovery, so as to prevent data inconsistency, realize task allocation, and avoid misreading and misreading Judgment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

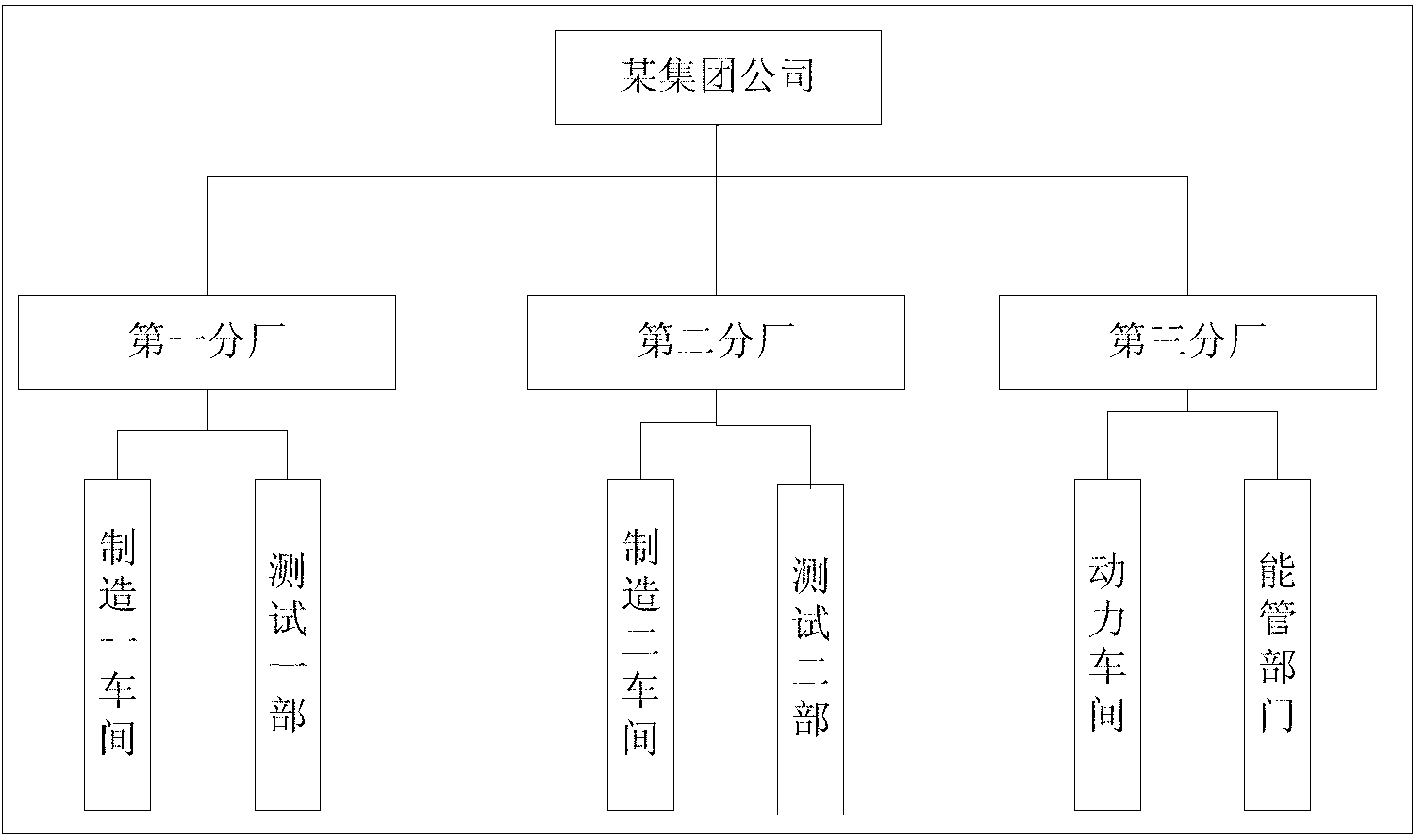

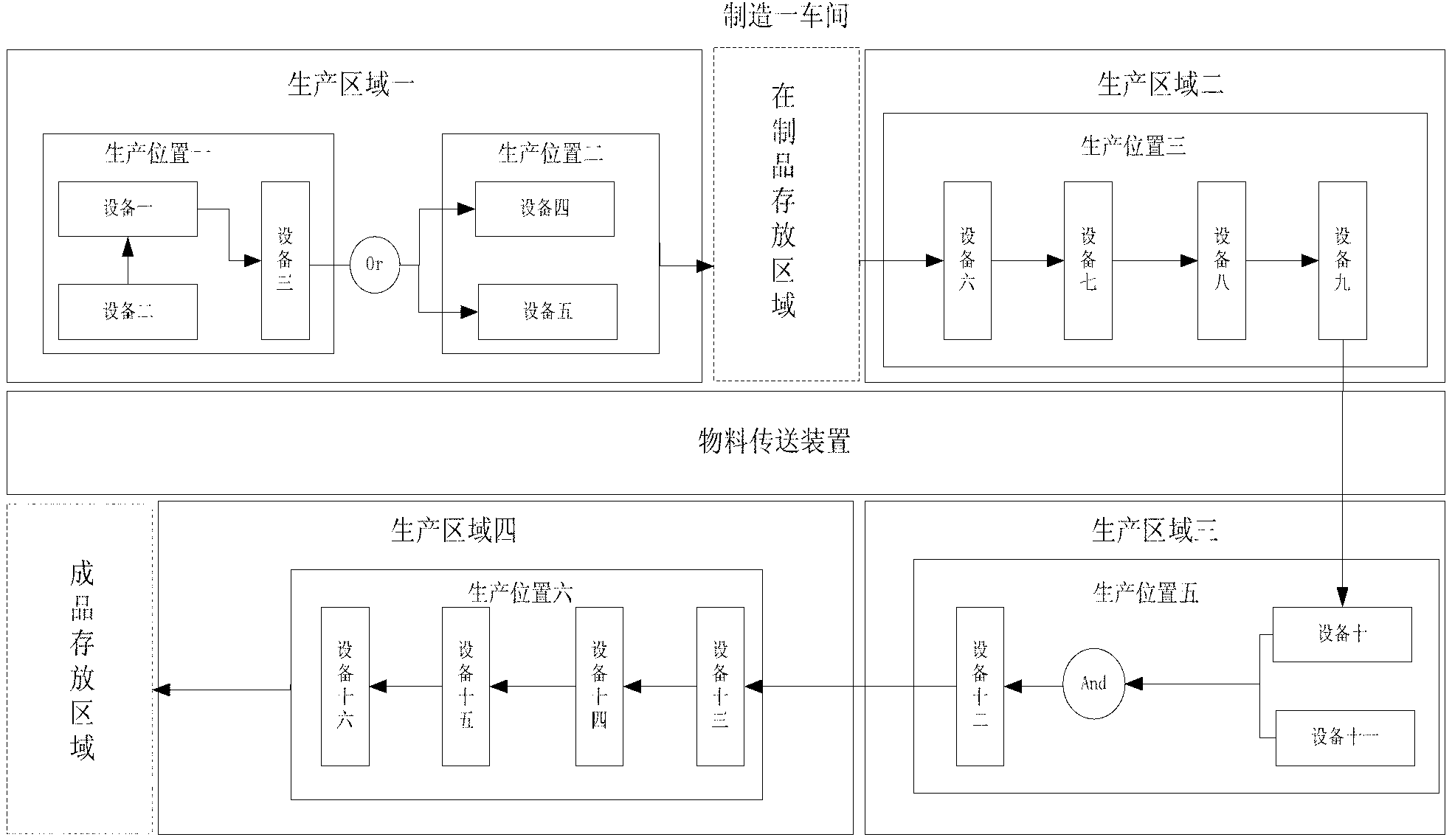

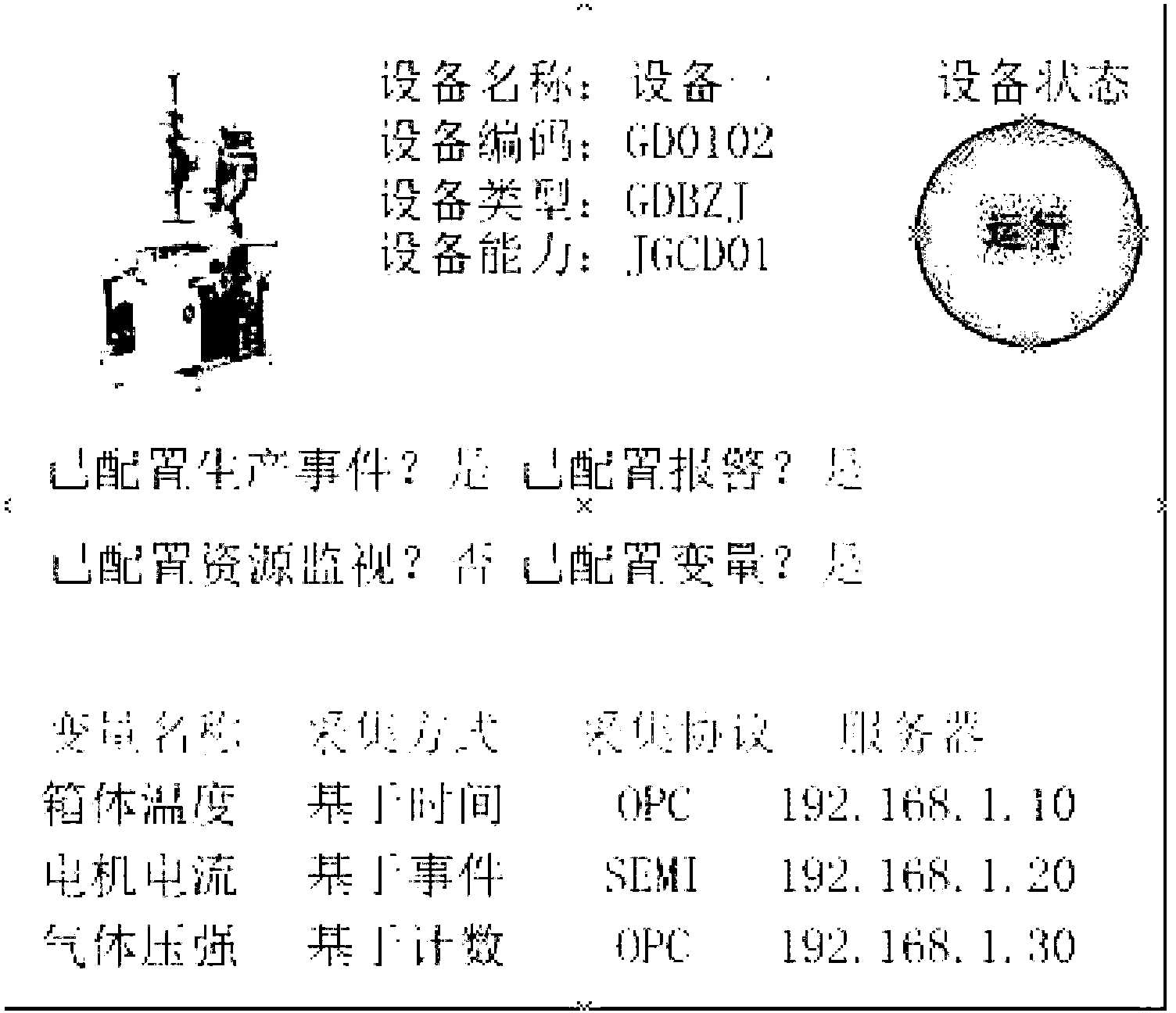

[0036] The invention is realized through the following technical proposals: a three-layer structure of organizational structure model-physical layout model-equipment model is proposed. This method is based on the basic graphic elements of the static model, and uses the way of visual graphics to dynamically configure the associations and relationships between the graphic elements to form a group organizational chart and departmental physical layout diagram, and build a visualized and configurable digital factory. Model. The present invention abstracts the three basic semantic elements of the group, branch and department from the organizational structure related to production, and forms an organizational structure model supporting the group-branch structure by configuring the basic connection relationship; The physical layout abstracts the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com