Light-emitting diode (LED) driver and lighting device with same

A technology for LED drivers and lighting devices, applied in lighting devices, output power conversion devices, instruments, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

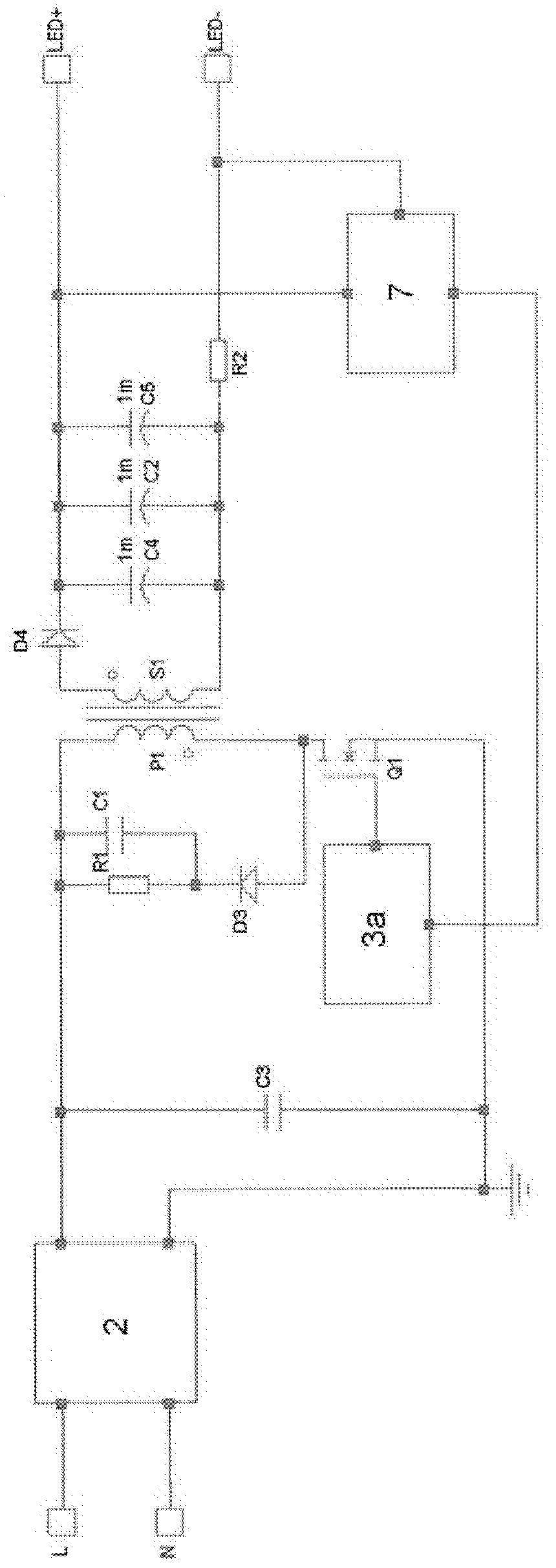

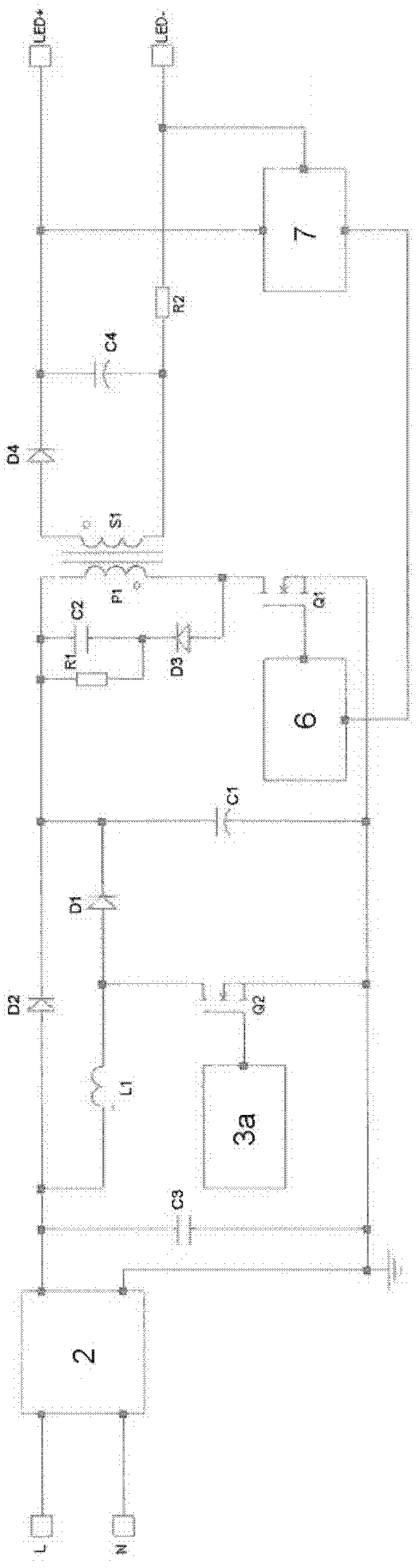

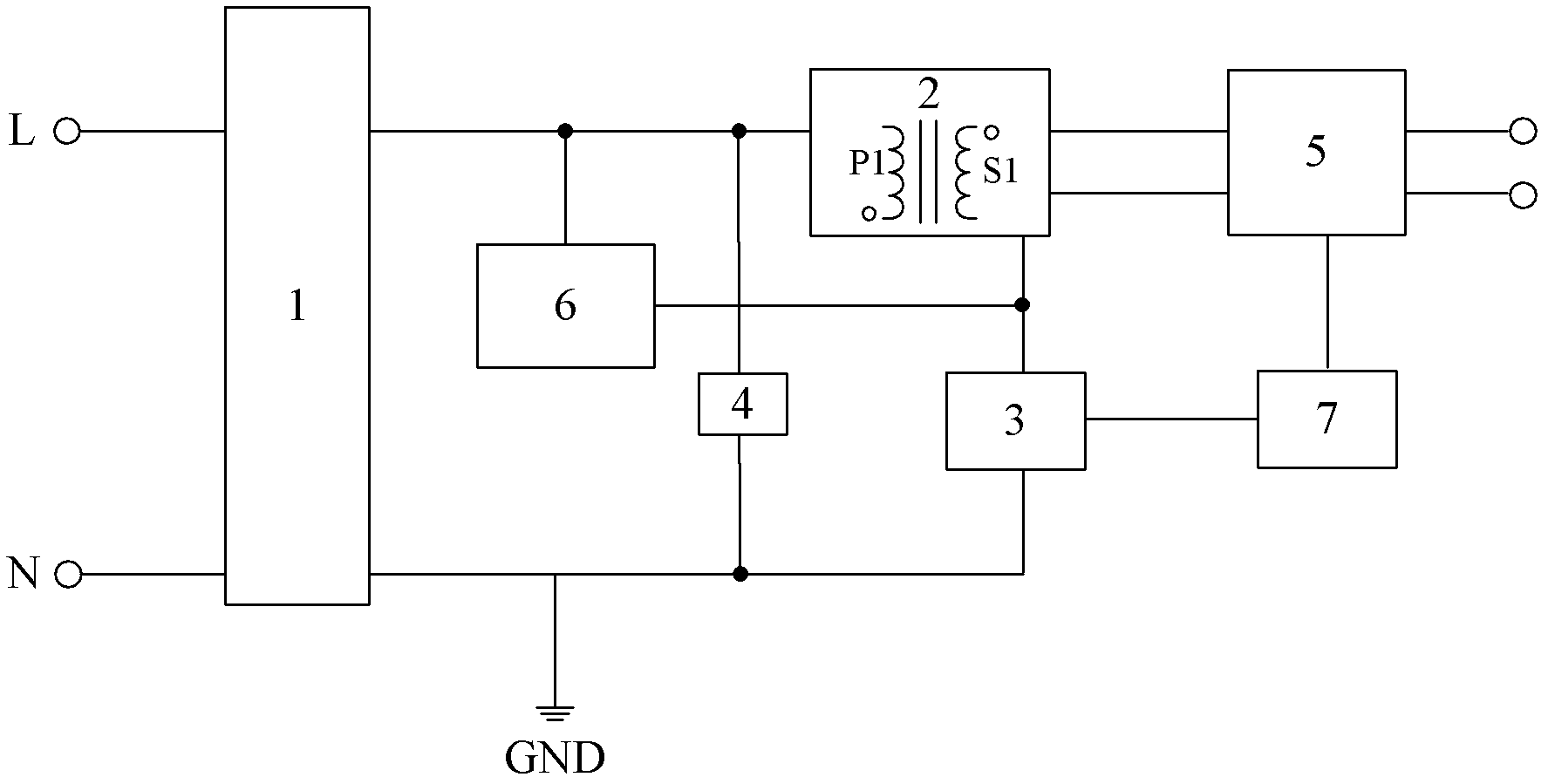

[0027] image 3 A functional block diagram of an LED driver according to the present invention is shown. As can be seen from the figure, the LED driver includes a rectifier bridge 1; a converter 2 connected to the rectifier bridge 1, the converter 2 includes a primary coil P1 and a secondary coil S1; a primary filter unit 4, the first end of the primary filter unit 4 Connected between the first end of the primary coil P1 and the rectifier bridge 1, the second end is connected to the ground GND; the switch unit 3, connected to the second end of the primary coil P1, controls the connection between the primary coil P1 and the ground GND; and the secondary The stage output unit 5 is connected to the secondary coil S1. It can be further seen from the figure that the LED driver also includes a boost input unit 6, the first end of the boost input unit 6 is connected between the rectifier bridge 1 and the first end of the primary coil P1, and the second end of the boost input unit 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com