Method for representing blending uniformity of cut leaves, expanded cut tobacco and cut stems

A technology of uniformity and cut stems, applied in the direction of tobacco preparation, application, tobacco, etc., can solve the problems of time-consuming, high cost, and the sample cannot be recycled, and achieve the effect of simple and practical method and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

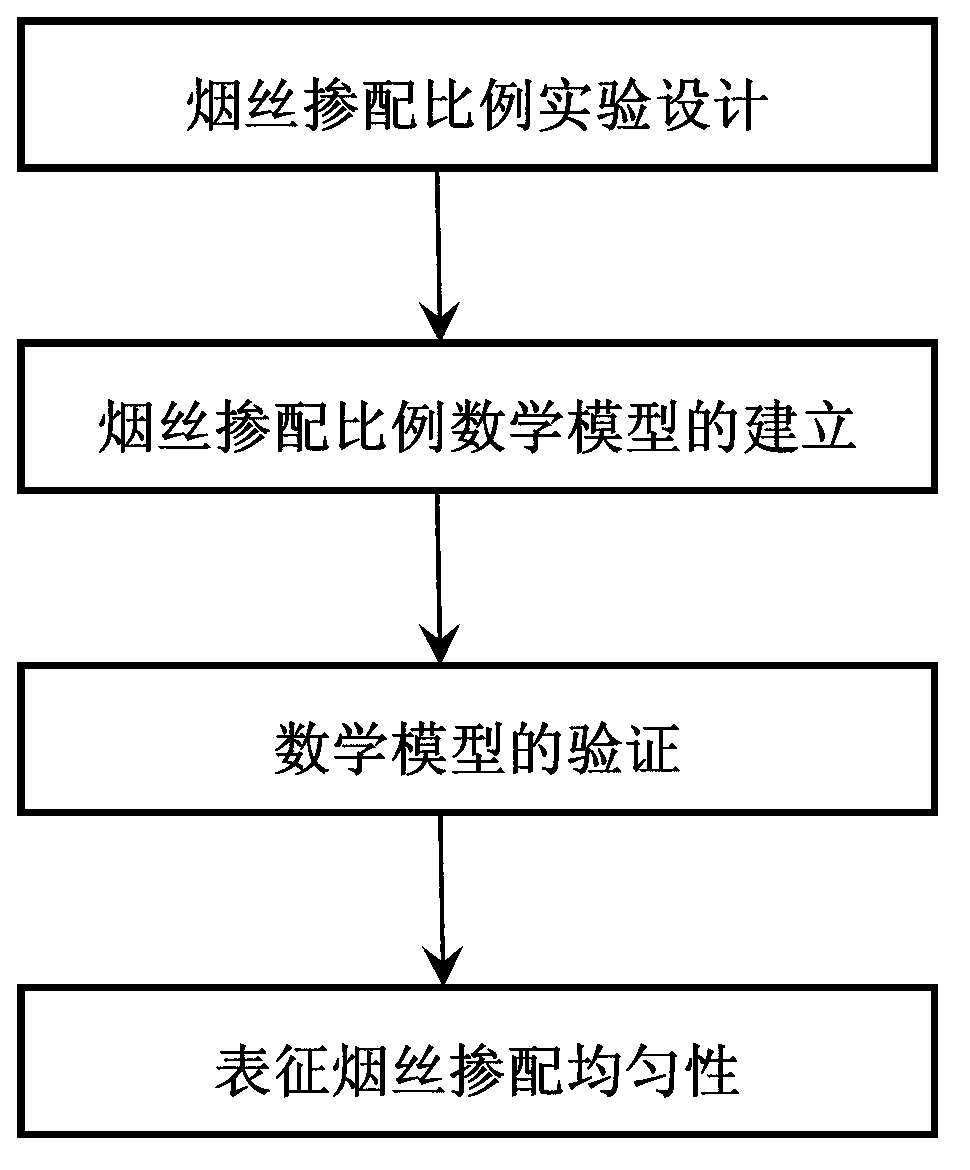

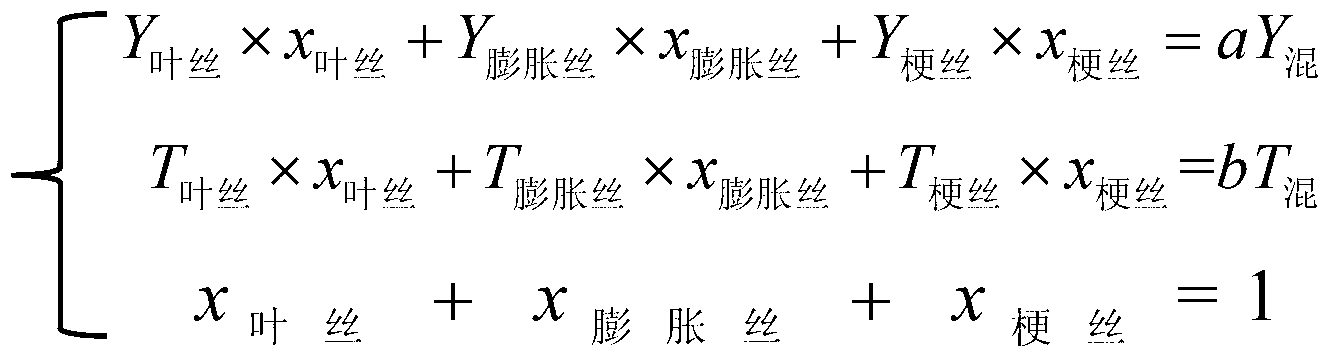

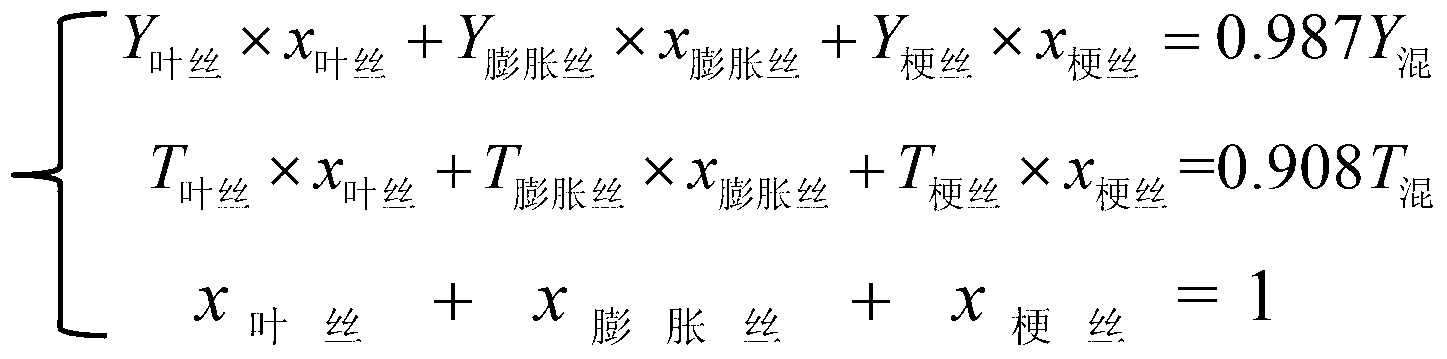

Method used

Image

Examples

Embodiment 1

[0023] Taking trivalent cigarettes as the implementation object, the shredded tobacco blending ratio in the shredded tobacco formula is: 58% shredded leaves, 30% expanded shredded shreds and 12% shredded stems. Specific steps are as follows:

[0024] 1. Experimental design of cut tobacco blending ratio: (1) Take 30 samples of Yunyan (purple) mixed cut tobacco that needs to be characterized for blending uniformity, measure their filling value and shredded ratio respectively, and obtain the variation range of the filled value and shredded ratio (2) According to the blending ratio of shredded tobacco in the Yunyan (purple) formula, and centering on the blending ratio of this formula, set a certain range of blending ratios of shredded leaves, expanded shreds and cut stems, and determine the two when the blending ratio changes the most. Filling value and shredded shredded rate of a blended shredded tobacco, to obtain the variation range of the filled value and shredded shredded rat...

Embodiment 2

[0035] The method step of embodiment 2 is basically consistent with embodiment 1, and its difference with embodiment 1 is:

[0036] (1) Taking monovalent cigarettes as the implementation object, the shredded tobacco blending ratio in the shredded tobacco formula is: 71% shredded leaf tobacco, 23% shredded expanded tobacco and 6% shredded stem. (2) In the proportioning experiment design: the variation range of shredded leaves is 60.00% to 100.00%, the variation range of expanded silk is 0.00% to 30.00%, and the variation range of cut stems is 0.00% to 10.00%.

[0037] The results showed that the average blending ratio of shredded leaves was 70.81%, and the blending uniformity was 83.69%.

Embodiment 3

[0039] The method step of embodiment 3 is basically consistent with embodiment 1, and its difference with embodiment 1 is:

[0040](1) Taking high-end monovalent cigarettes as the implementation object, the blending ratio of shredded tobacco in the shredded tobacco formula is: 82% shredded leaves, 10% shredded shreds and 8% shredded stems. (2) In the experimental design of the ratio of shredded leaves, expanded silks and cut stems: the variation range of shredded leaves is 70.00% to 100.00%, the variation range of expanded silks is 0.00% to 20.00%, and the variation range of cut stems is 0.00% to 10.00%.

[0041] The results showed that the average blending ratio of shredded leaves was 82.49%, and the blending uniformity was 81.87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com