Pipeline type steam filter screen with double-funnel structure

A double-funnel, pipeline technology, applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problem of high difficulty in screen inspection and disassembly, inability to meet the requirements of the filter screen structure, and inability to meet the flow area of the filter screen, etc. problems, to achieve the effect of simplifying the external fixed structure, low cost, and strong structural applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

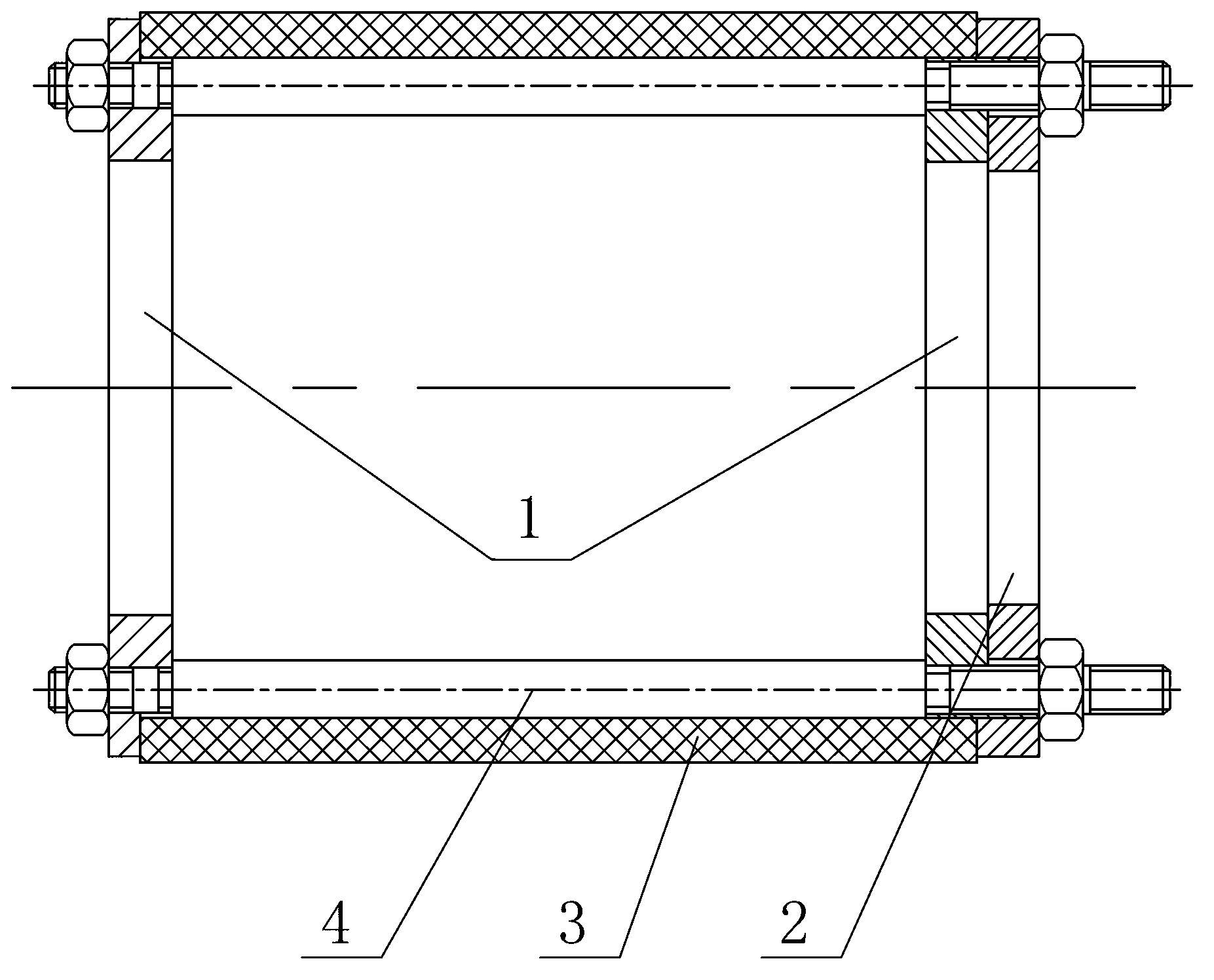

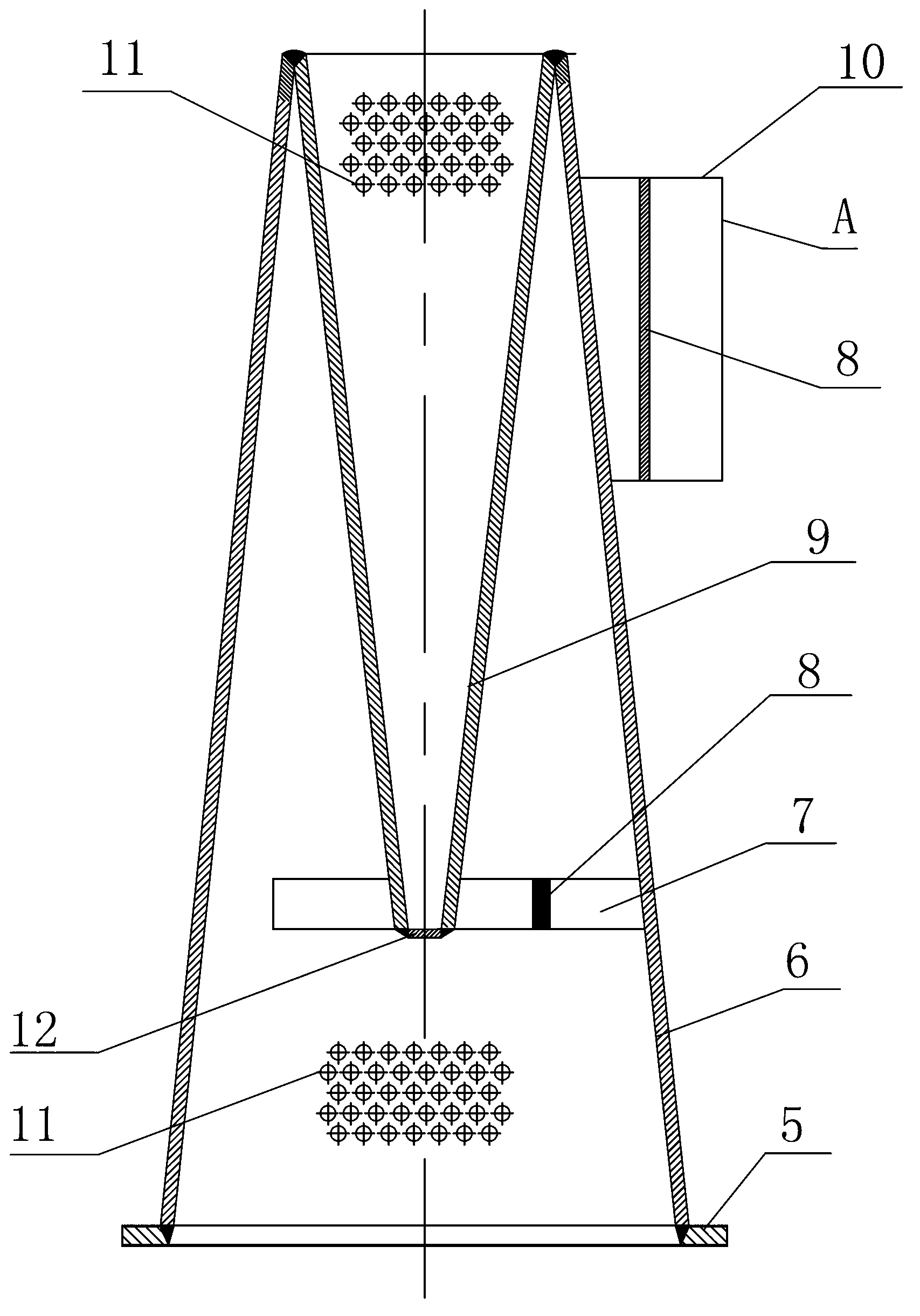

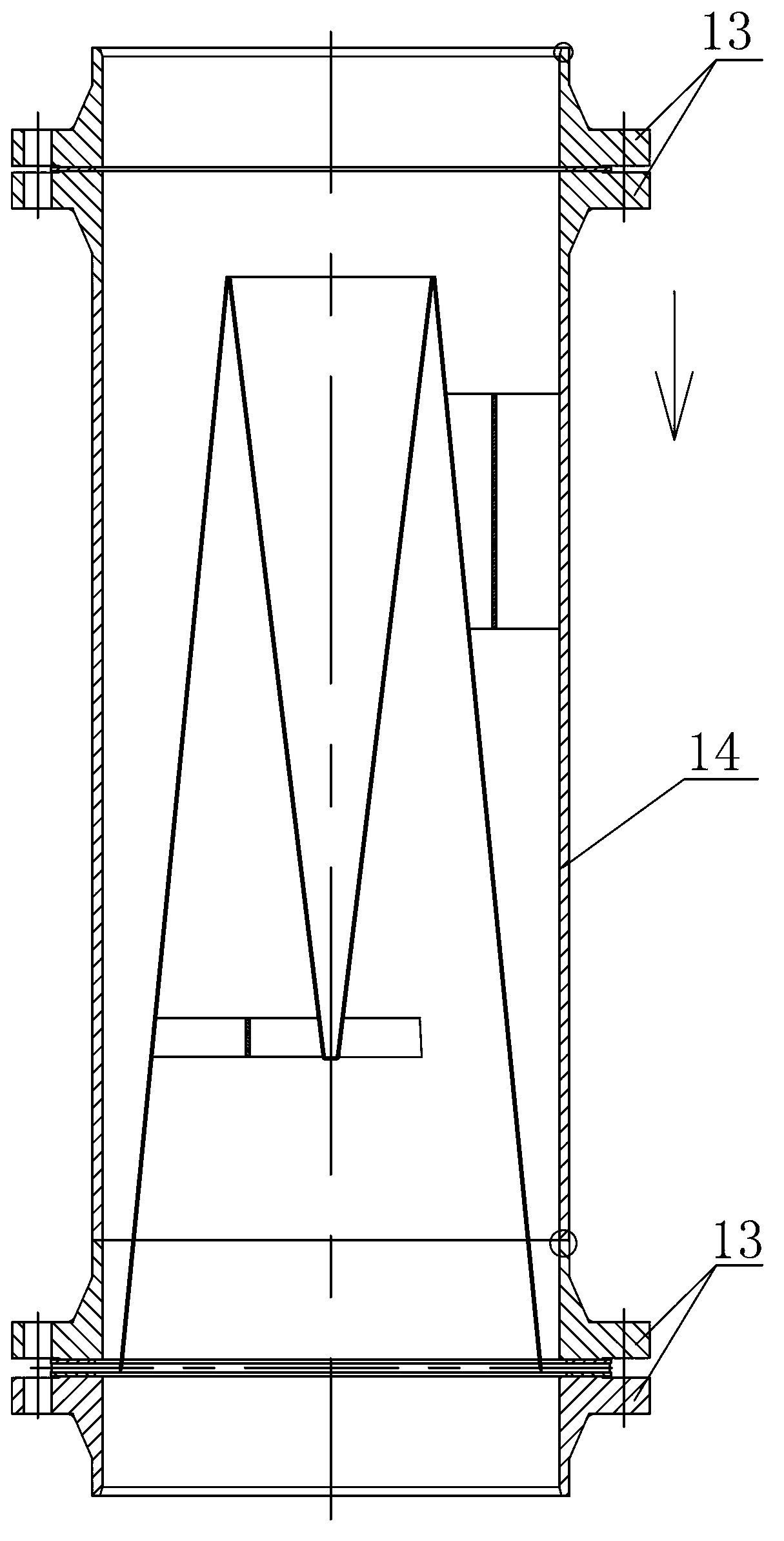

[0019] Such as figure 2 , image 3 As shown, the pipeline-type double-funnel steam filter screen of the present invention includes a funnel-shaped outer net 6 and an inner net 9 coaxially arranged; the diameter of the outer net gradually decreases from its bottom end to the top end, and its The bottom end is formed with a flange ring 5, and the mouth at the top is connected (welded together) to the top of the inner net; the inner net extends downward into the interior of the outer net (the length of the inner net is about 50 to 80 %, according to the actual needs to determine the length ratio of the inner net and the outer net), the diameter of the inner net gradually decreases from its top to the bottom.

[0020] The nozzle at the bottom of the inner net is provided with a fixed ring 12 (welded and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com