A wide base radial tread arc tire

A radial and tread technology, applied to tire tread/tread pattern, tire parts, transportation and packaging, etc., can solve the problems of complex molding and assembly process, increased tire quality, thickened tire shoulder, etc., to achieve wear Uniformity, improved stiffness distribution, and uniform ground pressure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

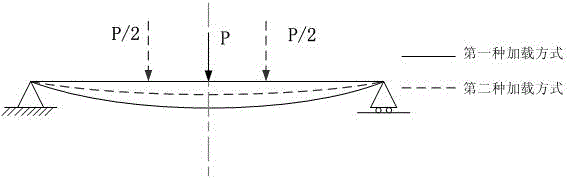

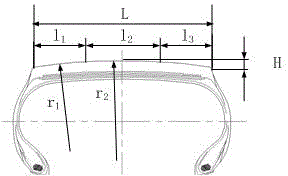

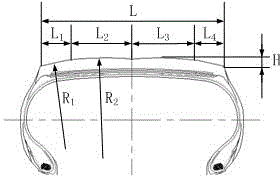

[0017] The section of traditional wide-base radial tire is as follows: figure 2 As shown, the tread arc is given by l 1 , l 2 and l 3 Composed of three arcs. For ordinary radial tires, this method is simple and easy, and the overall performance of the tire is good. However, for wide-base radial tires, due to the wide tread, it is difficult to control the deformation of the crown when the tire touches the ground. The three-segment arc wide-base radial Tires often show vase-shaped and hourglass-shaped footprints in the ground, such as Figure 4 , 5 shown. This shape is a macroscopic manifestation of uneven ground pressure distribution. Such tires are often scrapped early due to local excessive wear during use, which greatly reduces the service life of the tire. Similarly, the uneven distribution of ground pressure will also affect the grip performance of the tire.

[0018] Therefore, how to control the deformation of the tire crown during the ground contact process is ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com