Lightweight structure method of planetary gear reduction gearbox

A technology of planetary gear reduction and structural method, which is applied in the field of machinery, can solve problems that affect the working efficiency of the hoist, the stiffness cannot meet the expected requirements, and the weight of the box is large, so as to avoid uneven stiffness distribution, optimize stiffness distribution, reduce Effect of Overall Wall Thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

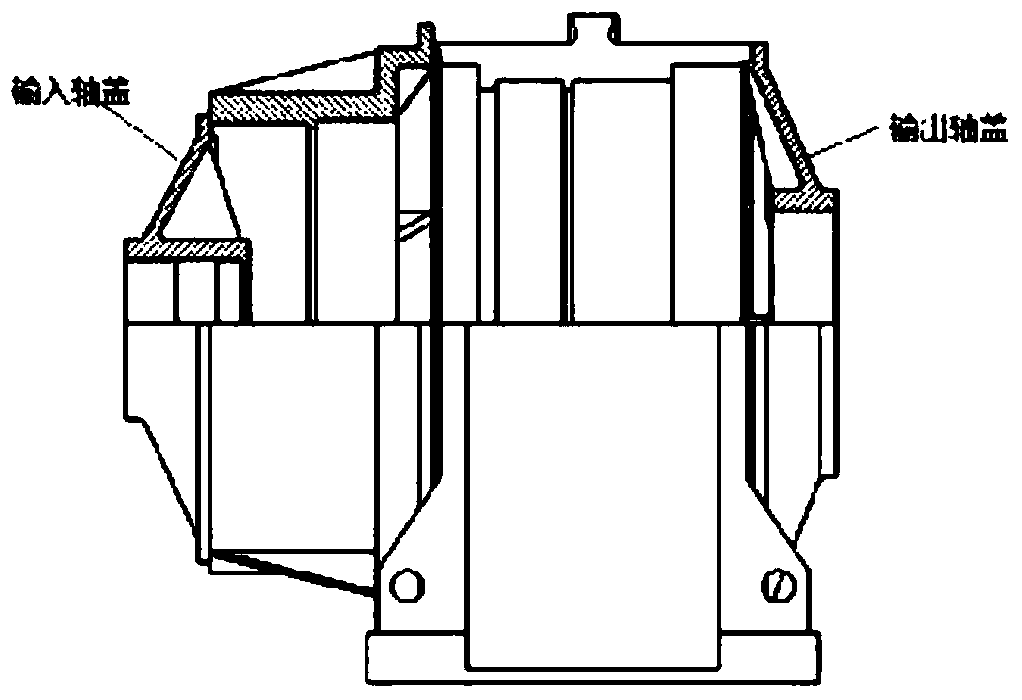

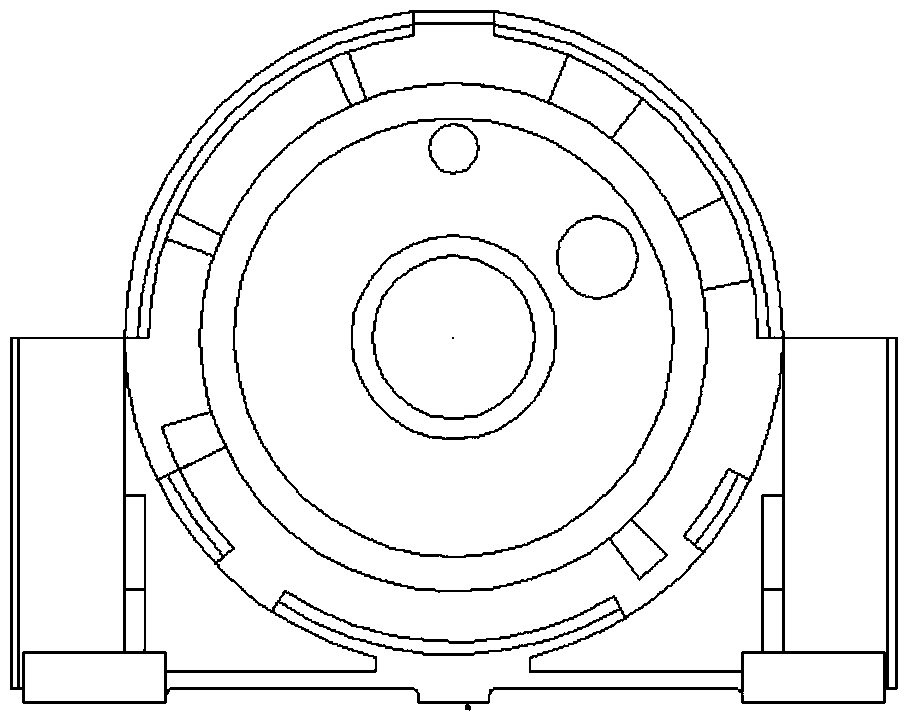

[0028] The present invention will be further described below in conjunction with accompanying drawing and embodiment: figure 1 It is a structural schematic diagram of the gear box of the present invention, figure 2 It is the left view of the gearbox structure of the present invention.

[0029] The lightweight structure method of the planetary gear reduction gearbox provided by the present invention includes

[0030] a. Establish a 3D model of the gear box structure,

[0031] b. Through dynamic analysis, obtain the load force when the gearbox is subjected to the maximum stress during operation,

[0032] c. Obtain the displacement nephogram of the 3D model through static analysis,

[0033] d. According to the load force at the time of the maximum stress obtained by dynamic analysis and the maximum displacement obtained by static analysis, the position to be strengthened is obtained,

[0034] e. Strengthen the rigidity of the position to be reinforced, and reduce the thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com