Toughened glass electromagnetic heating furnace

A technology of electromagnetic heating furnace and tempered glass, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high cost and uneven heating, and achieve the effect of reducing cost and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

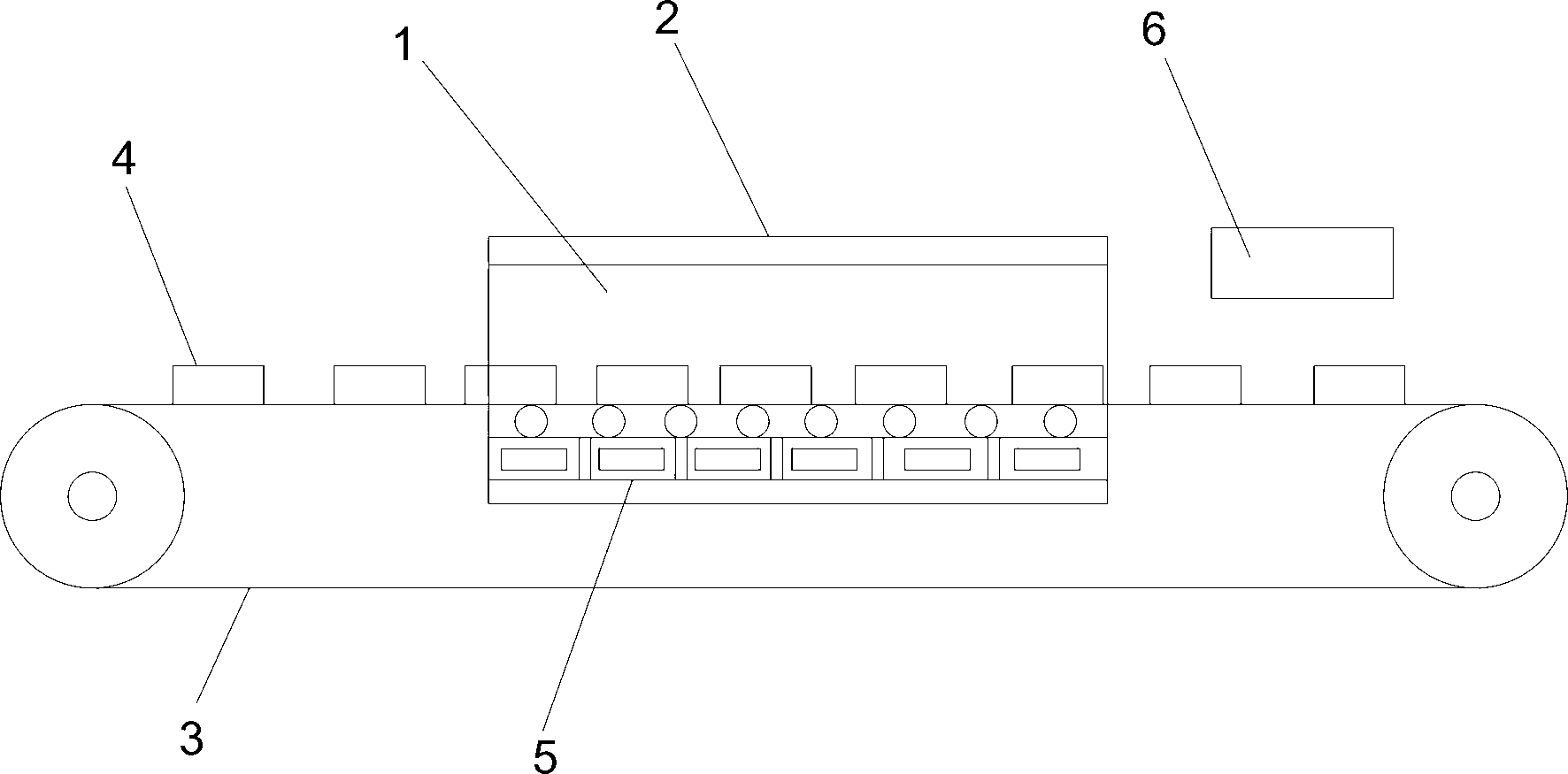

[0014] Such as figure 1 , figure 2 As shown, a tempered glass electromagnetic heating furnace is composed of a furnace body 1, an insulation layer 2, a conveyor belt 3, a mold cover 4, a heating module 5 and a cooling fan 6.

[0015] Furnace body 1 is a rectangular parallelepiped box with inner hollow, and the outside of furnace body 1 is wrapped with insulation layer 2; A heating module 5 is provided at the lower part of the conveyor belt; a cooling fan 6 is provided at the exit of the furnace body 1 .

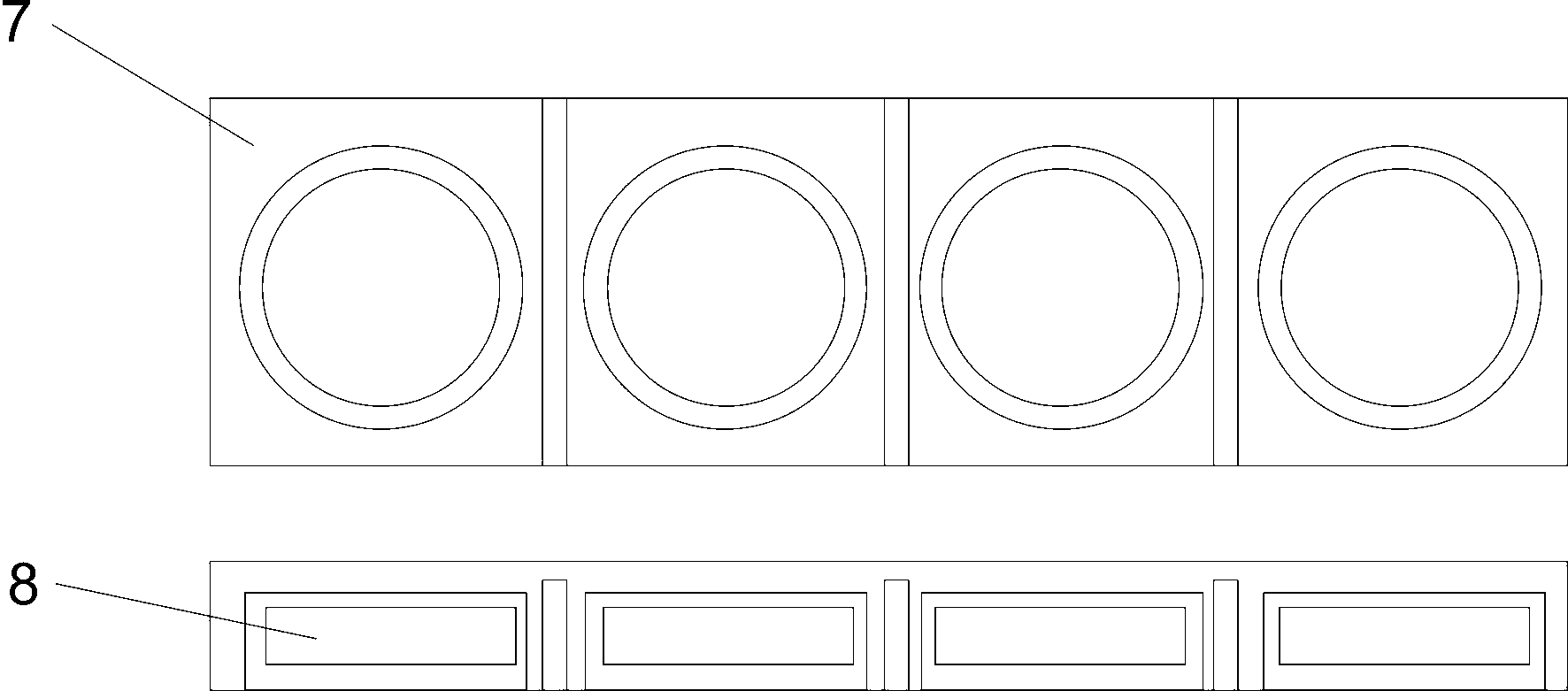

[0016] The heating module 5 is composed of a heat conduction substrate 7 and an electromagnetic heating coil 8 , the electromagnetic heating coil 8 is evenly embedded in the heat conduction substrate 7 , and strip grooves are provided on the heat conduction substrate 7 between adjacent electromagnetic heating coils 8 .

[0017] The strip grooves provided on the heat conduction substrate 7 between the electromagnetic heating coils 8 in the heating module 5 can effectively p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap