Hoisting method for replacing cooling wall in overhauling of blast furnace

A hoisting method and stave technology, applied to cooling devices and other directions, can solve problems such as stave burn-through, corrosion by molten iron, and inability to hoist the stave into the installation area, so as to reduce maintenance costs, save replacement time, and avoid Effects that cannot be hoisted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further describe the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0022] A method for hoisting and replacing staves for maintenance and maintenance of a blast furnace, characterized in that: it is carried out in accordance with the following steps:

[0023] 1. Make cooling wall special trays in the blast furnace

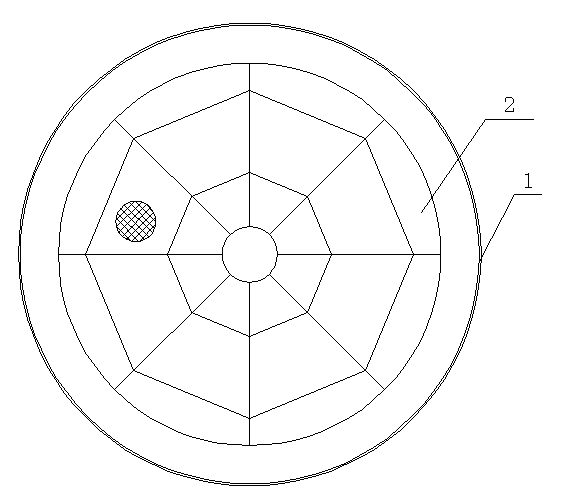

[0024] Such as figure 2 As shown in the figure, the workers transport materials such as I-beams, channel steels, and platform plates back into the blast furnace through the iron mouth frame, and make a cooling stave installation special tray 2 suitable for the inner diameter of the blast furnace shell 1 .

[0025] 2. Unimpeded cooling stave hoisting special channel

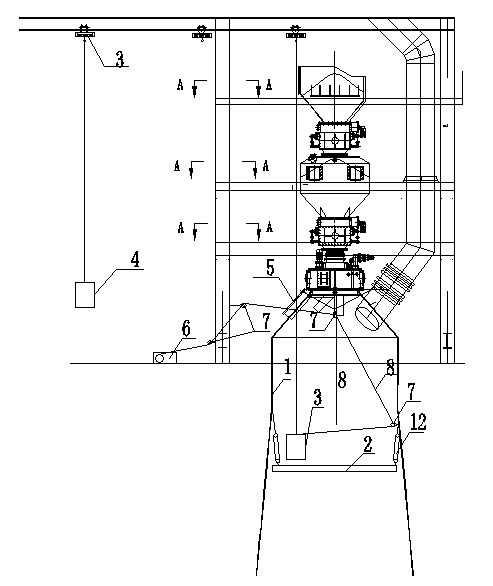

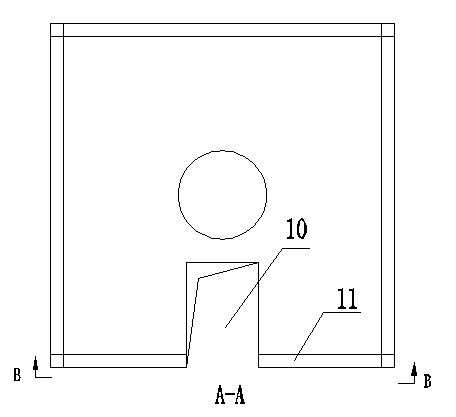

[0026] Such as image 3 , Figure 4 As shown, from the bottom of the blast furnace top inspection hoist to the platform of each layer of the furnace top platform, a special channel 9 for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com