Guide roller structure for warp knitting machine carbon fiber yarns

A carbon fiber yarn and guide roller technology, which is applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problems of carbon fiber yarn twisting, folding, large left and right swings, and affecting weaving quality, so as to ensure fabric quality and avoid left and right swings , the effect of preventing torsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

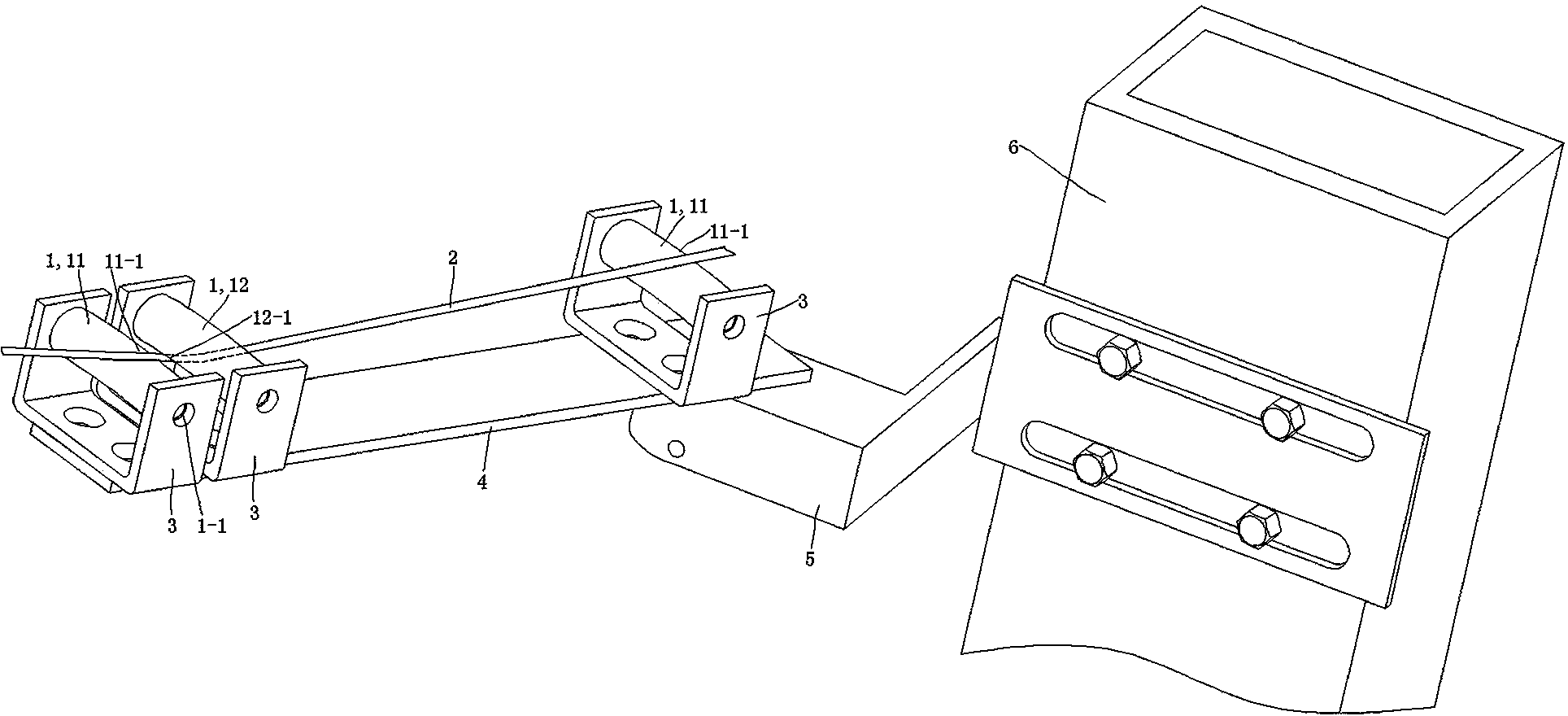

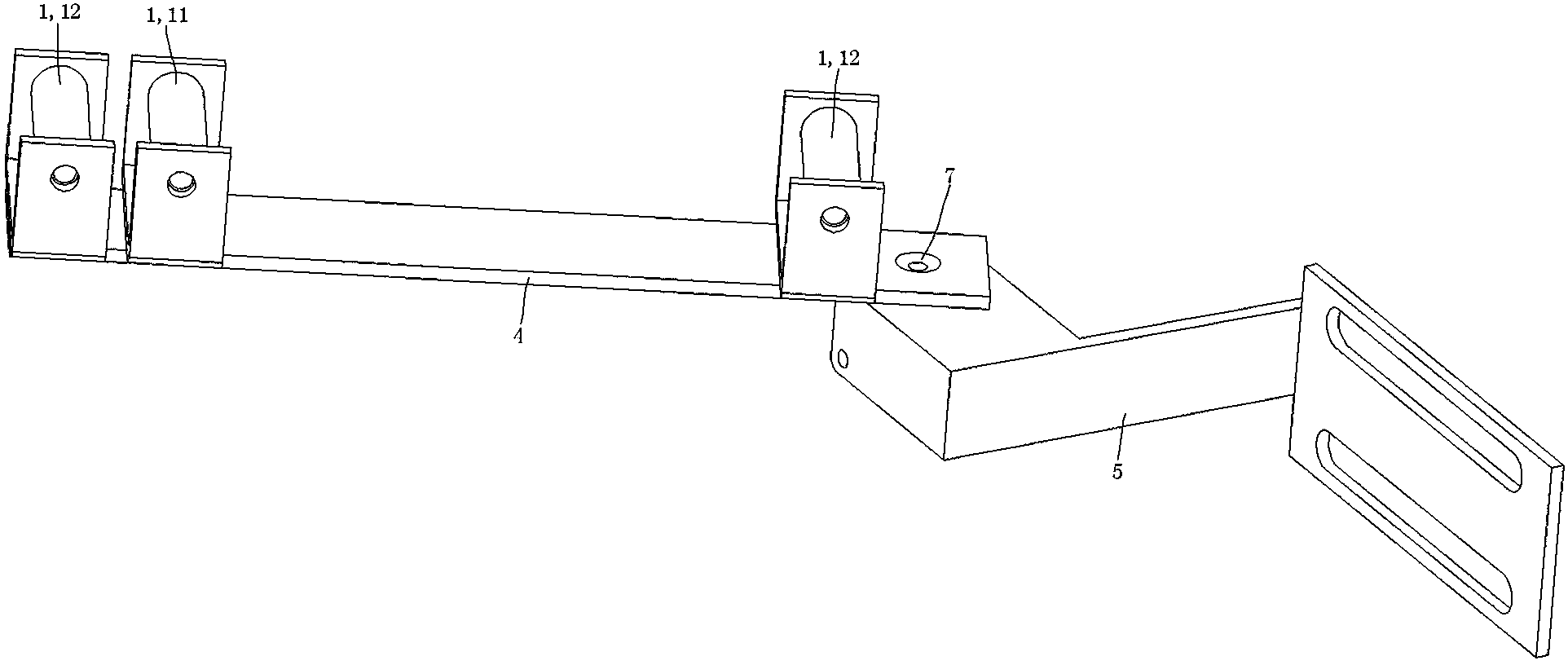

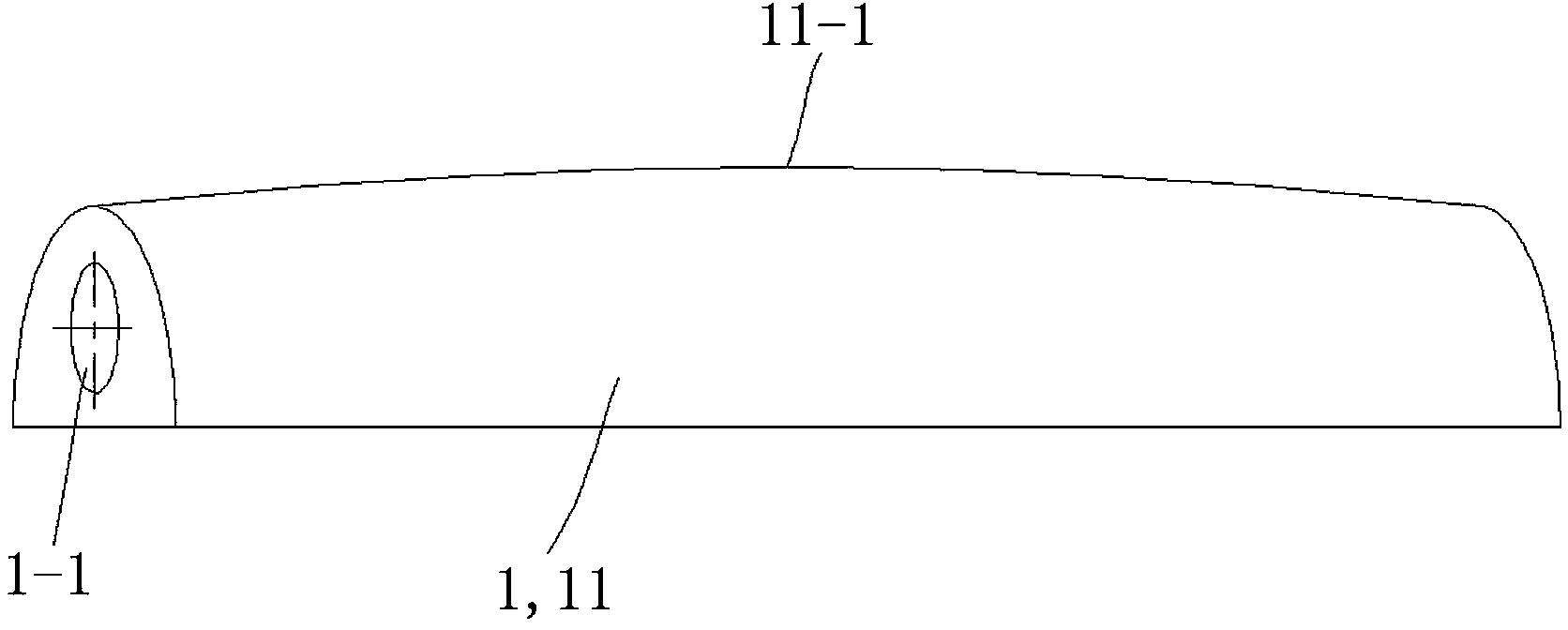

[0030] see Figure 1 to Figure 13 The shown guide roller structure for warp knitting machine carbon fiber yarn includes several guide rollers 1. During operation, the carbon fiber yarn 2 is unwound from the yarn storage mechanism, and is guided and transported to the weaving mechanism by the guide roller 1 for weaving. , the guide roller 1 is divided into an outer convex guide roller 11 with an outer convex arc surface 11-1 and an inner concave guide roller 12 with an inner concave arc surface 12-1, the outer convex guide roller 11 and the inner concave guide roller 12 Guide rollers 12 are respectively fixedly mounted on guide roller bearings 3, and said guide roller bearings 3 are installed on the frame of the warp knitting machine, and said outer convex guide rollers 11 and inner concave guide rollers 12 are arranged at intervals, that is, from storage In the direction from the yarn mechanism to the weaving mechanism, if the first guide roller is set as the convex guide roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com