Papermaking device and papermaking method

A technology for papermaking equipment and paper webs, which is applied in papermaking, papermaking machines, textiles, and papermaking, etc. It can solve the problems of lengthening household paper processing processes, and achieve the effects of reducing the burden of water removal, saving energy, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

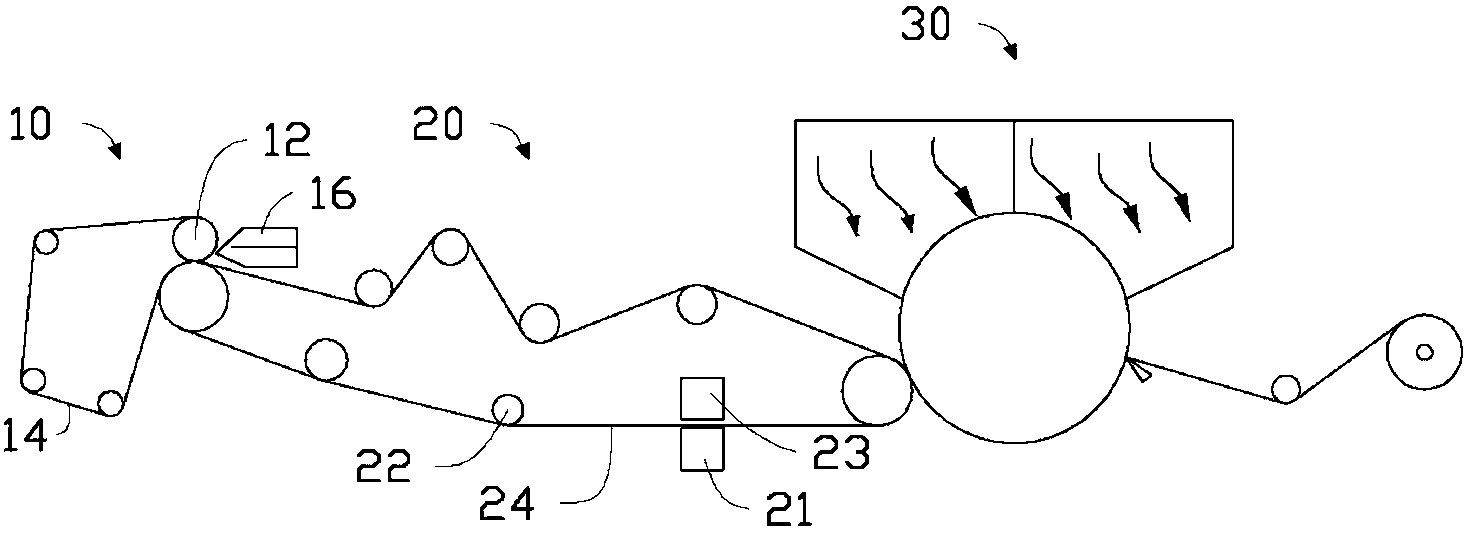

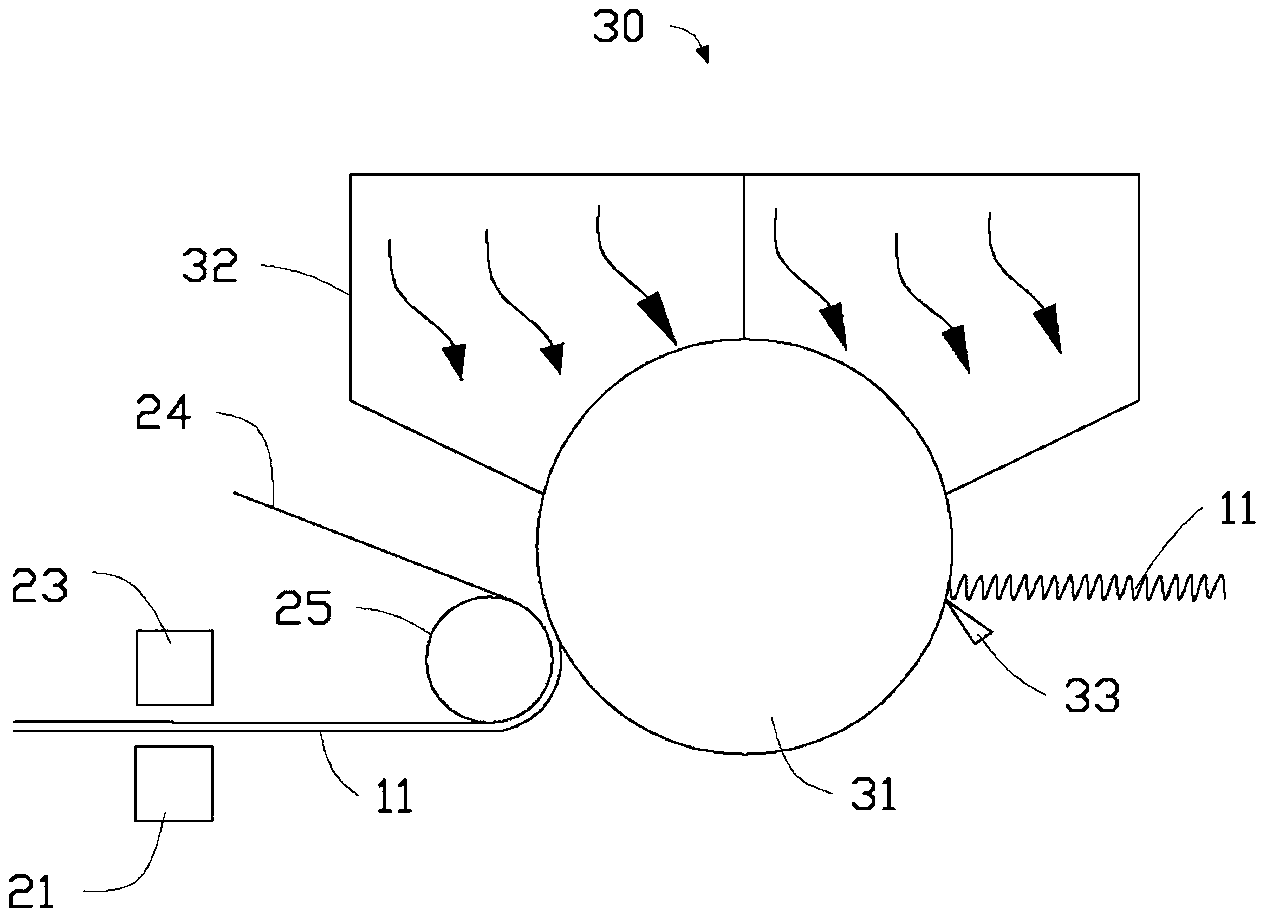

[0021] Such as figure 1 and figure 2 As shown, the papermaking equipment of an embodiment provided by the present invention is used for making tissue paper. The papermaking plant comprises a forming section 10 , a wet transfer section 20 and a drying section 30 .

[0022] The forming section 10 includes a series of guide rolls 12 and a fabric 14 moving around the guide rolls 12 , and a headbox 16 . The fabric 14 forms an endless loop. A suspension of raw fibers for papermaking is cast via a headbox 16 onto a fabric 14 and forms a paper web 11 on the moving fabric 14 . The web 11 is brought to the junction of the forming section 10 and the wet transfer section 20 by the movement of the fabric 14 and transferred to the wet transfer section 20 .

[0023] figure 1 Only one headbox 16 is shown in , it can be understood that more can be set in actual production. Moreover, existing other types of molding units 10 can be used for the molding and papermaking of household paper i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com