Horizontal well subsection gravel pack tool

A technology for gravel packing and horizontal wells, which is applied in wellbore/well parts, production fluid, earthwork drilling and production, etc., which can solve the problems of reducing the number of sections and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

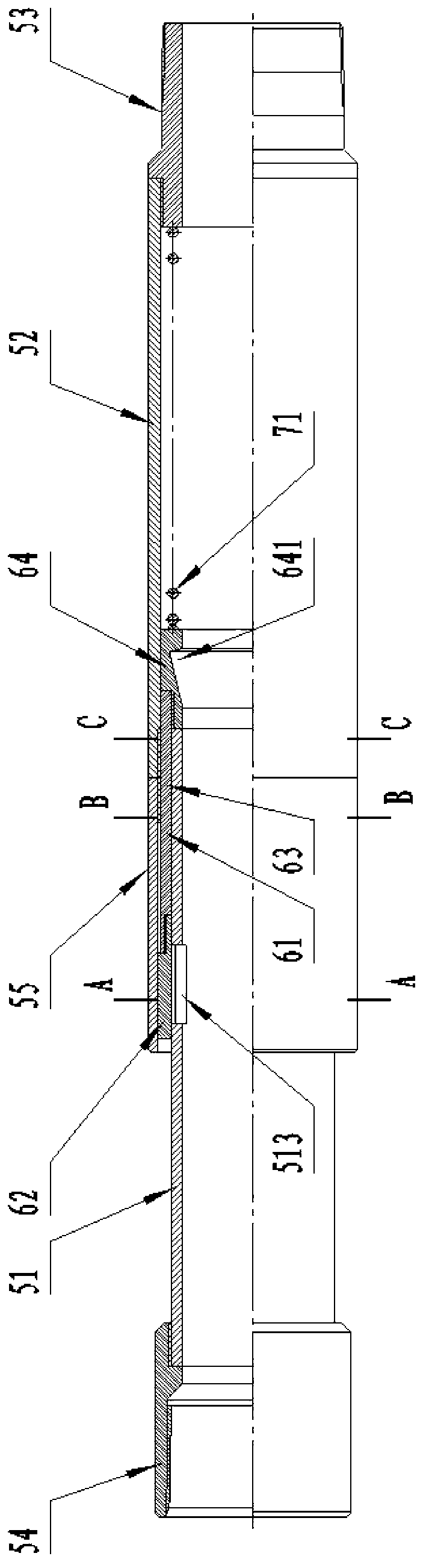

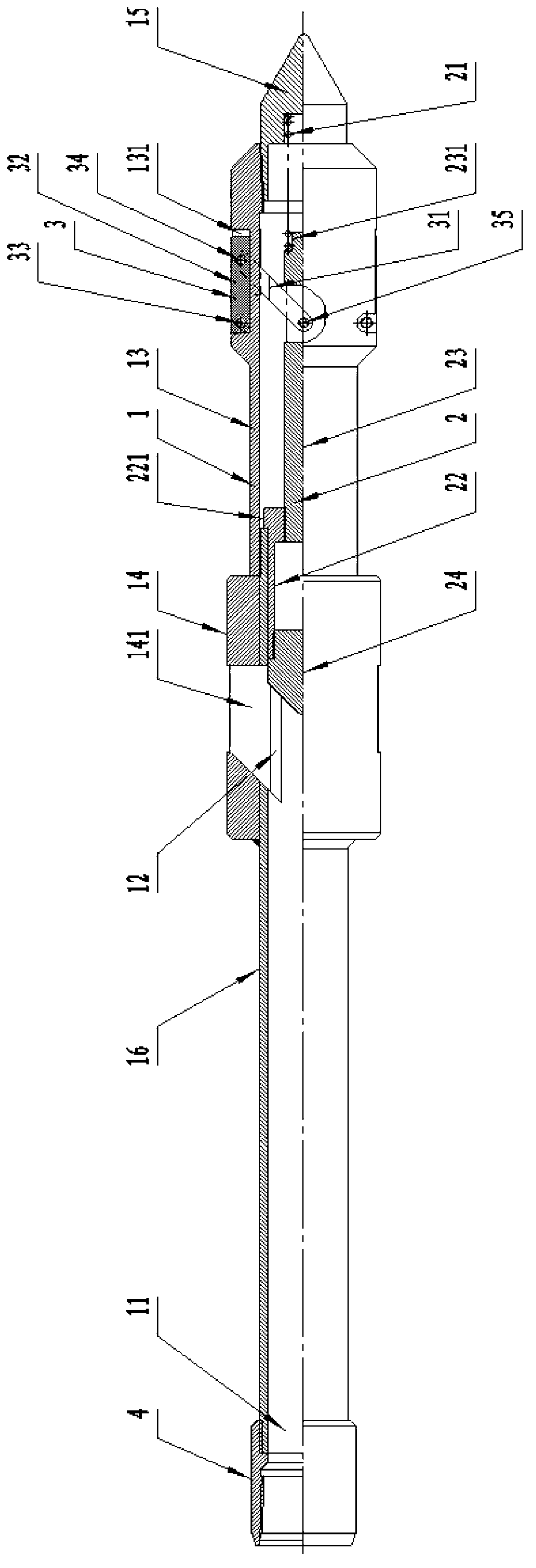

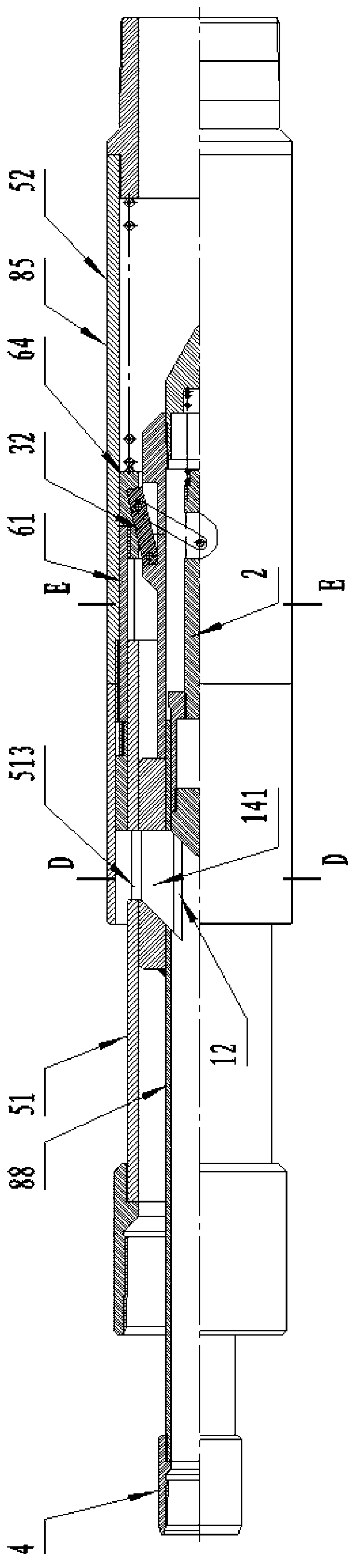

[0034] The sectioned gravel packing tool for horizontal wells according to the present invention will be described in detail below in conjunction with the accompanying drawings. A segmented gravel packing tool for horizontal wells, comprising a packing sleeve 51, an outer sleeve 52 and a switch sliding sleeve device 61; one end of the cylindrical packing sleeve 51 is sleeved in one end of the cylindrical outer sleeve 52, the The outer wall of one end of the filling cylinder 51 is provided with a plurality of protrusions 511 along the circumferential direction of the filling cylinder 51, and a receiving groove 512 is formed between two adjacent protrusions, and the filling cylinder 51 is fixedly connected with the outer sleeve 52 through the protrusions 511. 51 is provided with a filling hole 513 that can communicate with the inside and outside of the filling cylinder 51; the switch sliding sleeve device 61 includes a sliding sleeve 62, a bridging pipe 63 and a transmission ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com