Engine active temperature control system and control method thereof

A temperature control system and active technology, applied in engine components, machine/engine, engine cooling, etc., can solve problems such as high engine failure rate, high energy consumption, increased fuel consumption, etc., to prolong engine life and improve safety Performance and energy reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

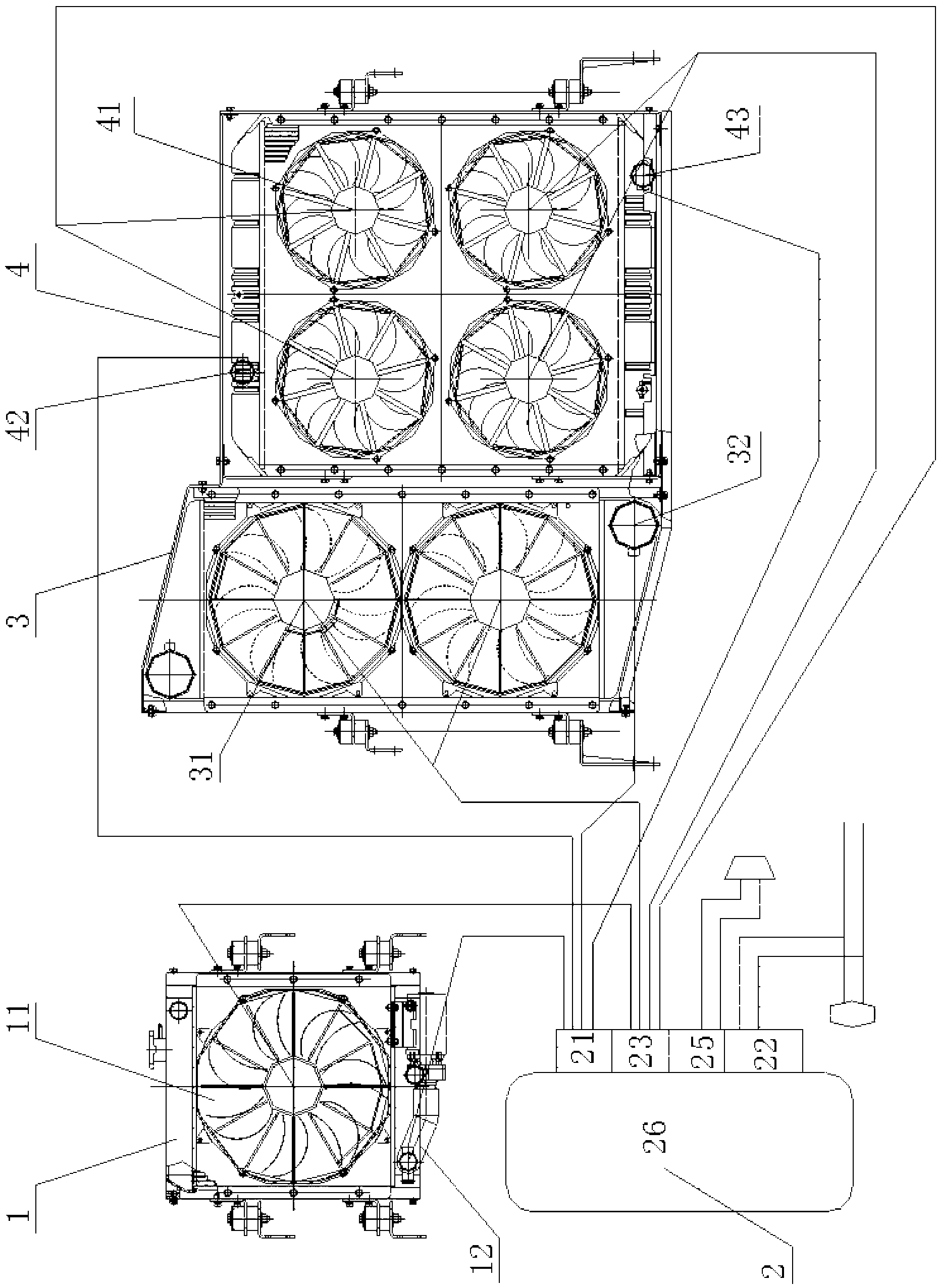

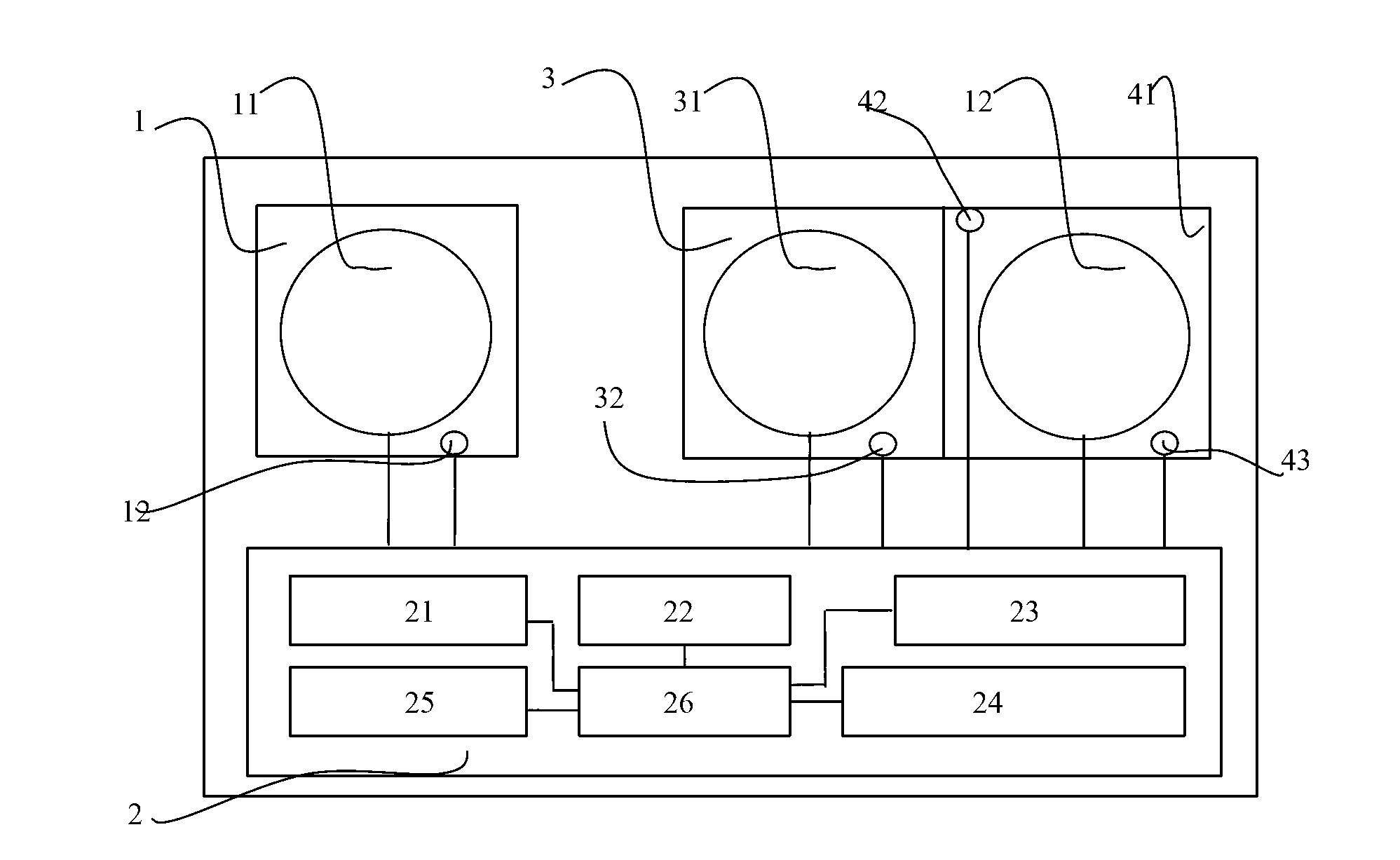

[0012] like figure 1 , figure 2 , the engine active temperature control system, which includes a motor radiator 1, a main power cooling device and a controller 2, a plurality of electronic fans A11 and a first water outlet sensor 12 are arranged in the motor radiator 1, and the main power cooling device It consists of an intercooler 3 and a radiator 4. The intercooler 3 is provided with a plurality of electronic fans B31 and an air outlet sensor 32. The radiator 4 is provided with a plurality of electronic fans C41, a water inlet sensor 42 and a second water outlet. Terminal sensor 43, controller 2 is made up of temperature acquisition module 21, temperature display module 22, PWM conditioning and drive module 23, fault detection and processing module 24, communication module 25 and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com