Radial Thrust Bearings for Hydrogenerator Sets

A generator set, radial thrust technology, applied in the directions of hydropower generation, bearing cooling, bearing components, etc., can solve the problems affecting the normal operation of the unit, difficult radial bearing bush temperature, tile burning accident, etc., to reduce tile temperature, quickly and fully The effect of cooling and reducing accident rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

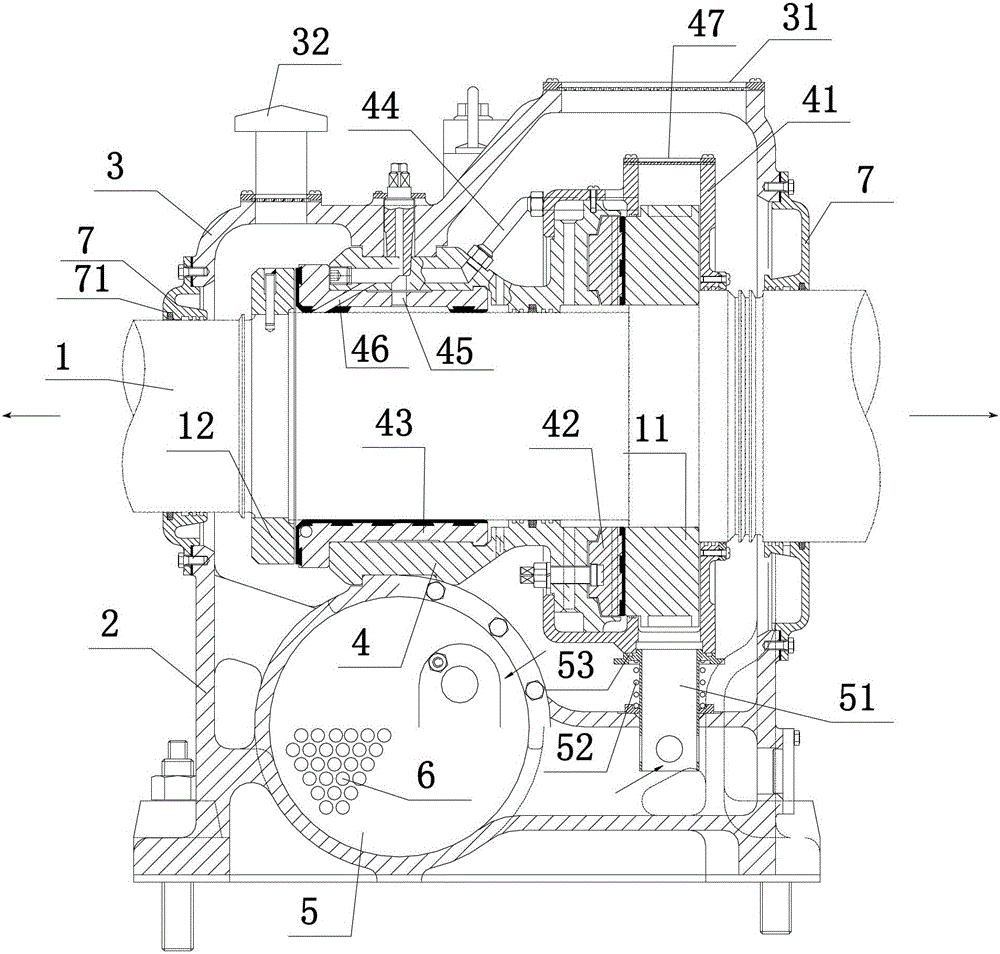

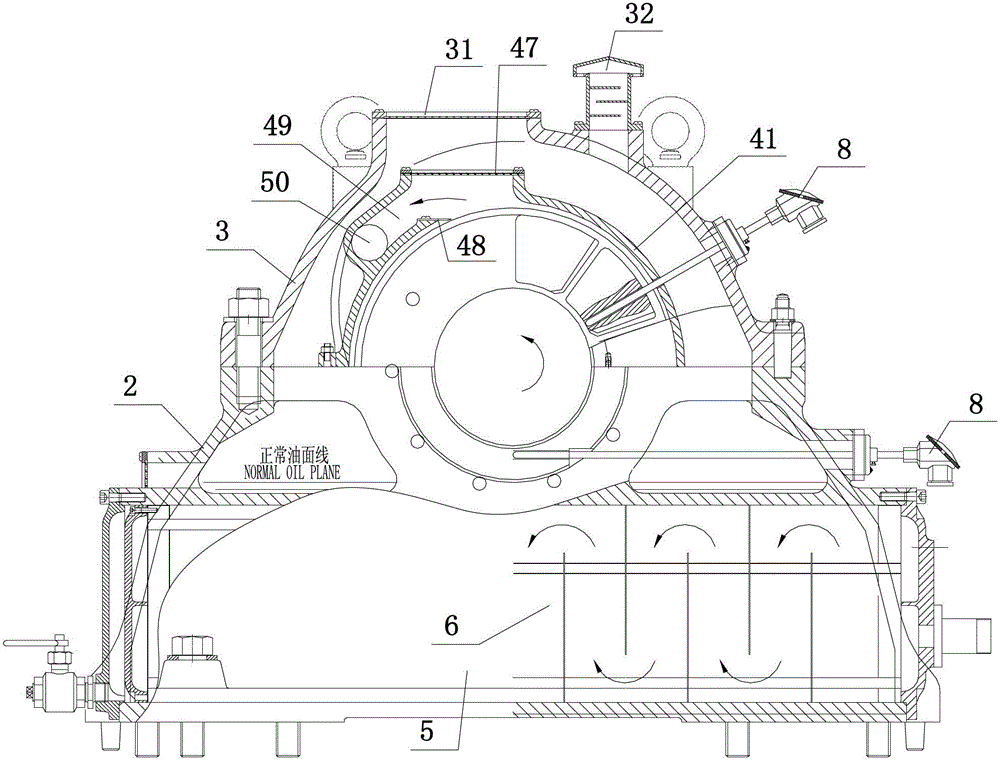

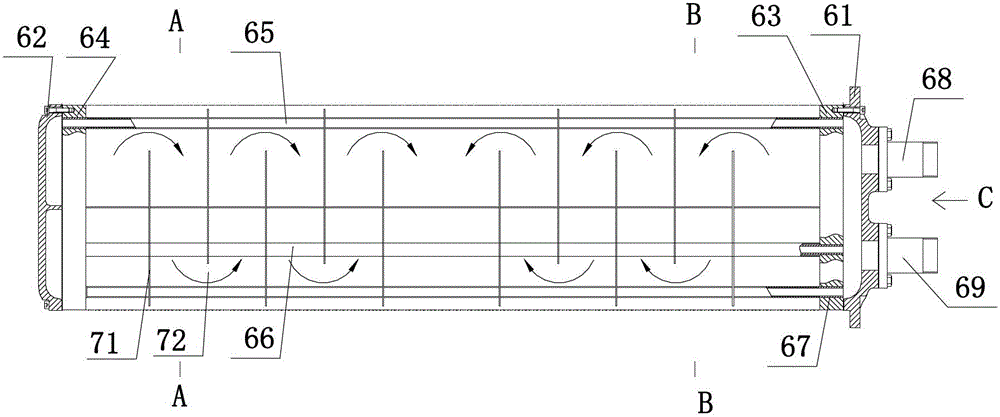

[0024] Such as figure 1 , figure 2 As shown, the radial thrust bearing of a hydroelectric generator set includes a main shaft 1, an outer shell and a bearing support 4, the outer shell includes a base 2 and a bearing upper cover 3, and bearing covers are respectively fixed at both ends of the outer shell 7. The bearing support 4 is set in the outer casing, the main shaft 1 is erected on the bearing support 4, the two ends of the main shaft 1 are matched with the bearing cap 7 respectively, and the bearing cap 7 is provided with an oil seal lock up. Such as figure 2 As shown, the right side of the main shaft 1 is fixed with a large thrust plate 11 , and the left side is fixed with a small thrust plate 12 . The right side of the bearing support 4 is provided with an oil inlet cover 41, the upper part of the oil inlet cover 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com