Cross-flow heat exchange equipment based on thermal convection process

A heat exchange equipment, cross-flow technology, used in heat exchange equipment, lighting and heating equipment, indirect heat exchangers, etc., can solve problems affecting service life and pressure bearing capacity, poor sealing performance, "pointing" corrosion It is convenient to disassemble and replace the heat exchange plate, shorten the heat exchange process, and improve the heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

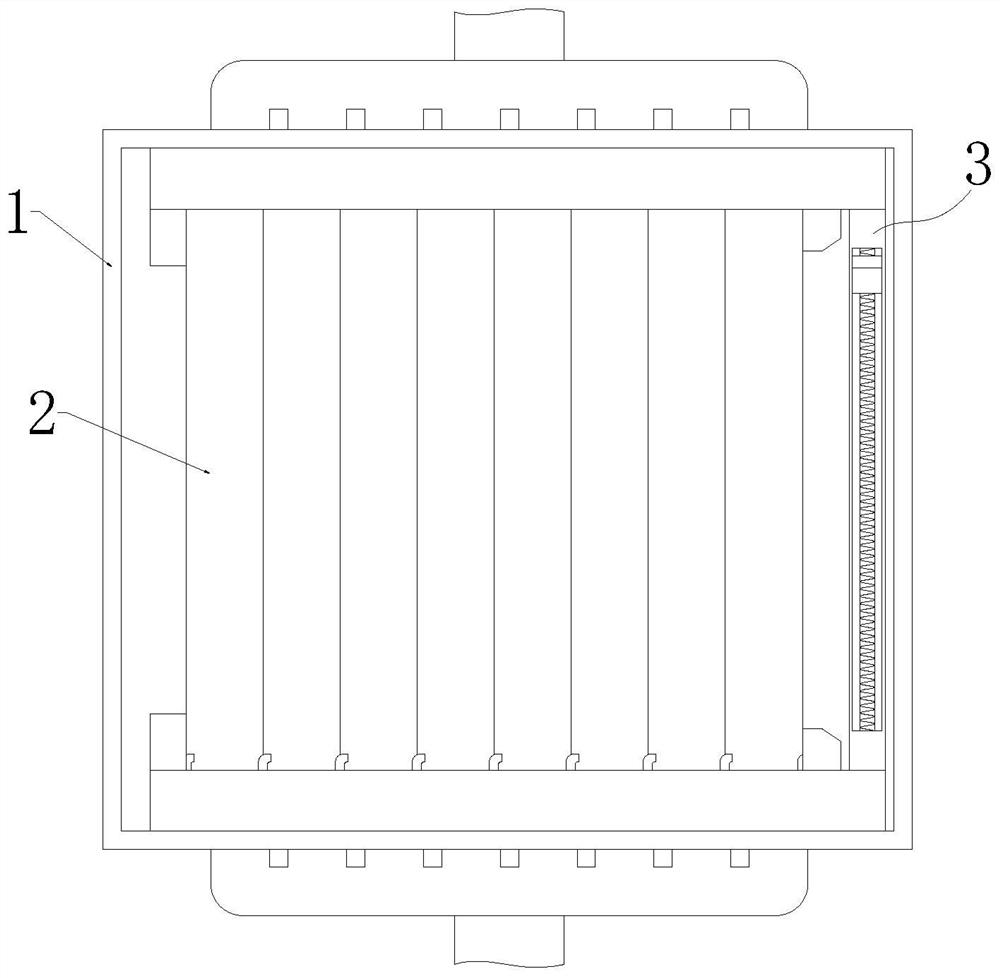

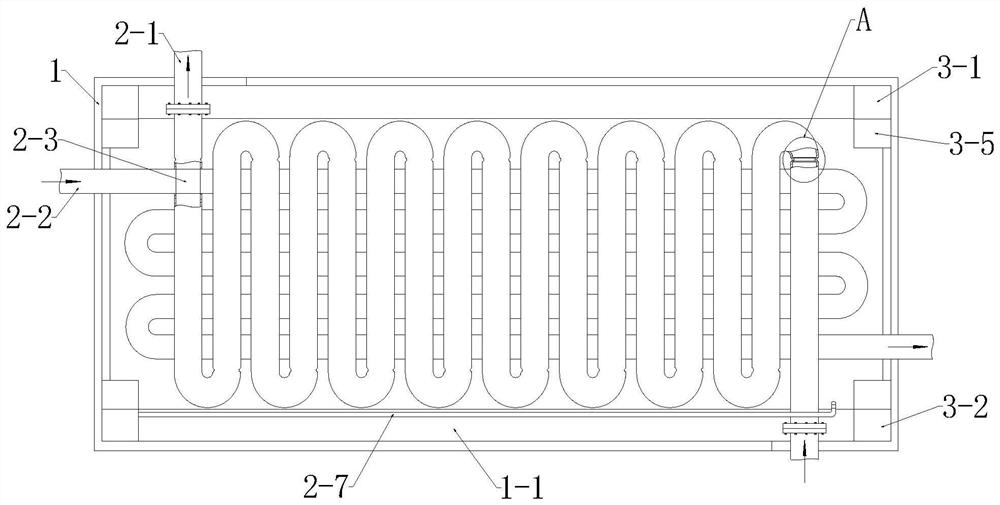

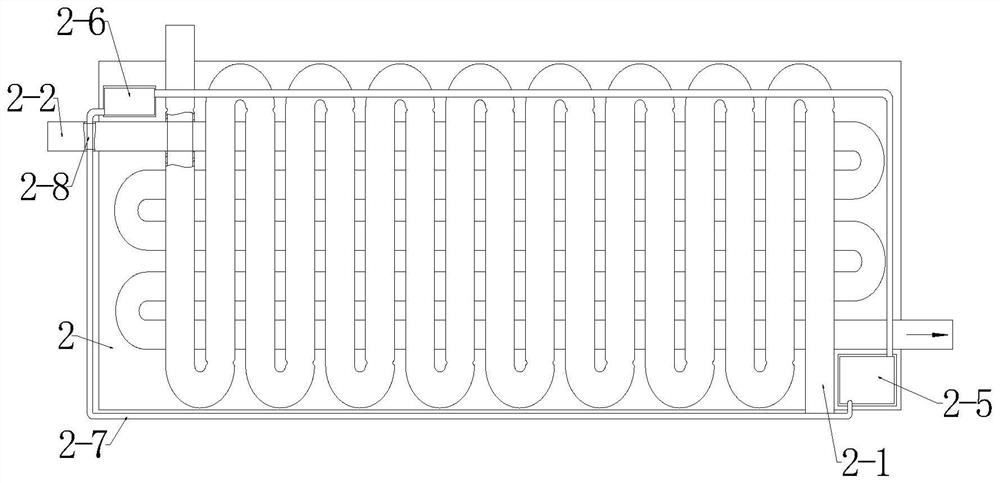

[0036] Example: such as Figure 1-8 As shown, the cross-flow heat exchange equipment based on the heat convection process, the heat exchange equipment includes a shell 1, several sets of heat exchange plates 2, and two sets of fixing mechanisms 3, and the two sets of fixing mechanisms 3 are fixed at the left and right ends of the shell 1 , several sets of heat exchange plates 2 are placed on two sets of fixing mechanisms 3, and the two sets of fixing mechanisms 3 fix several sets of heat exchange plates 2 in the casing 1, and the inside of the casing 1 is fixed with a heat insulation layer 1-1, and the heat insulation layer 1 -1 is located between at least two sets of fixing mechanisms 3, and the heat insulating layer 1-1 is made of heat insulating material.

[0037] Several groups of heat exchange plates 2 are equipped with heat flow tubes 2-1 and cold flow tubes 2-2, and several groups of cold flow tubes 2-2 are welded with several component flow tubes 2-3, and several compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com