Clutch reset device of knotter of square-bale bale press

A technology of reset device and baler, which is applied in the direction of mechanical drive clutch, clutch, packing, etc., can solve the problems of affecting the performance of the knotter, easy to wear each other, and increasing the working noise of the equipment, so as to reduce the cost of material selection and reduce the The effect of equipment working noise and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific implementation plan

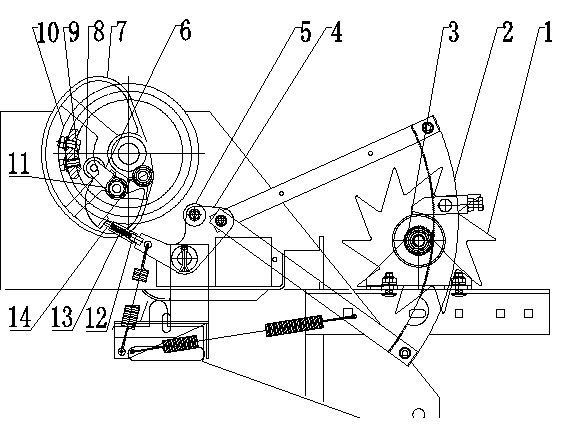

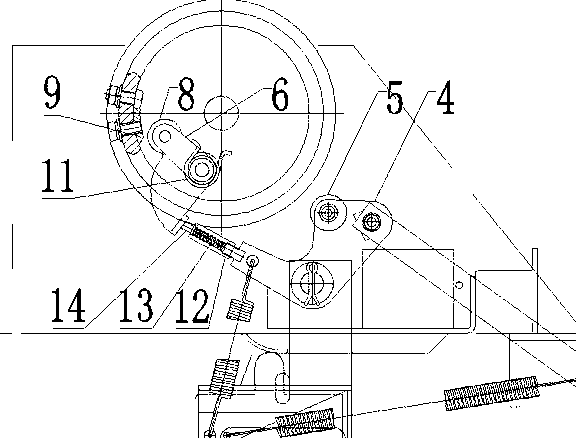

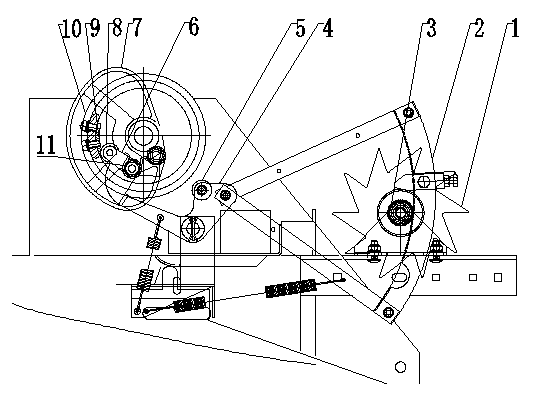

[0023] The technical features of the present invention will be described in further detail below in conjunction with the drawings:

[0024] The specific method is to install a spring seat 12 on the top of the original clutch reset plate 4, and install an adjustable return spring 13 and a spring top rod 14 in the spring seat 12.

[0025] The working principle of the present invention is as follows:

[0026] In the present invention, the original clutch reset plate 4 is replaced with a spring seat 12 on the top of the clutch reset plate 4, and a reset spring 13 and a spring top rod 14 are installed in the spring seat 12.

[0027] When it is in the pre-knotting stage: that is, when the bale has not reached the preset length, by adjusting the return spring 13, the improved spring return device 12, 13, 14 supports the clutch pawl 6, providing a clutch that can be engaged with the clutch The torque of the claw return spring 11 is balanced, so that ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com