Workstation system for solar water heater

A technology for solar water heaters and workstations, applied in solar thermal power generation, solar thermal devices, heating devices, etc., can solve the problems of wasting electricity, gradually decreasing, and unable to take a bath for users, achieving low installation costs and waste of electricity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

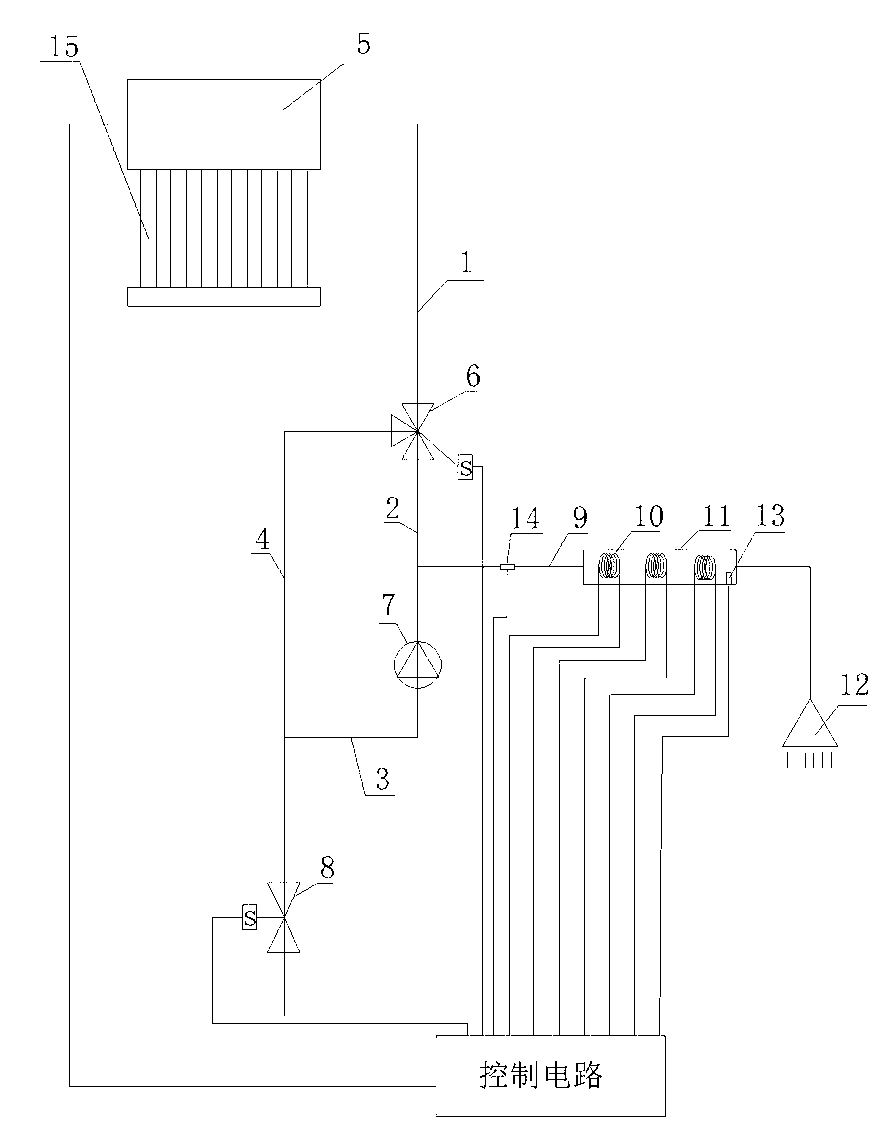

[0011] The details of its implementation and its working principle are specifically described below in conjunction with the accompanying drawings:

[0012] like figure 1 As shown, the solar water heater workstation system includes a first water pipe 1 connected to the solar water heater tank 5 and a water pump 7, a three-way valve 6 is provided between the water pump 7 and the solar water heater water tank 5, and the first interface of the three-way valve 6 The first water pipe 1 is connected to the water tank 5, the second port of the three-way valve 6 is connected to one end of the water pump 7 through the second water pipe 2, and the other end of the water pump 7 is connected to the water supply valve 8 through the third water pipe 3. A fourth water pipe 4 is connected between the three water pipe 3 and the third interface of the three-way valve 6, and a hot water outlet pipe 9 is also connected to the second water pipe 2, and the water in the hot water outlet pipe 9 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com