Shield butt sealing performance test device

A test device and technology of sealing performance, applied in the direction of liquid tightness measurement using liquid/vacuum degree, by measuring the rate of increase and decrease of fluid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] The invention is used for testing the sealing performance of the sealing member with various deviations such as axis deviation and uneven compression during installation.

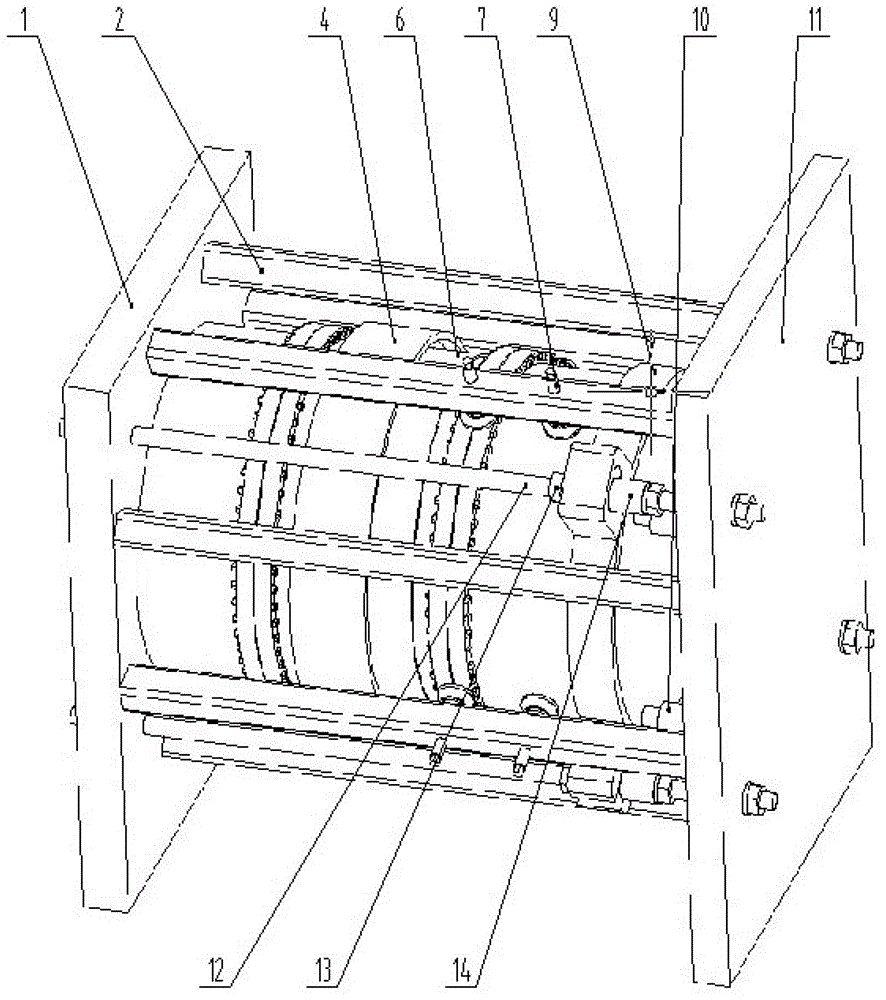

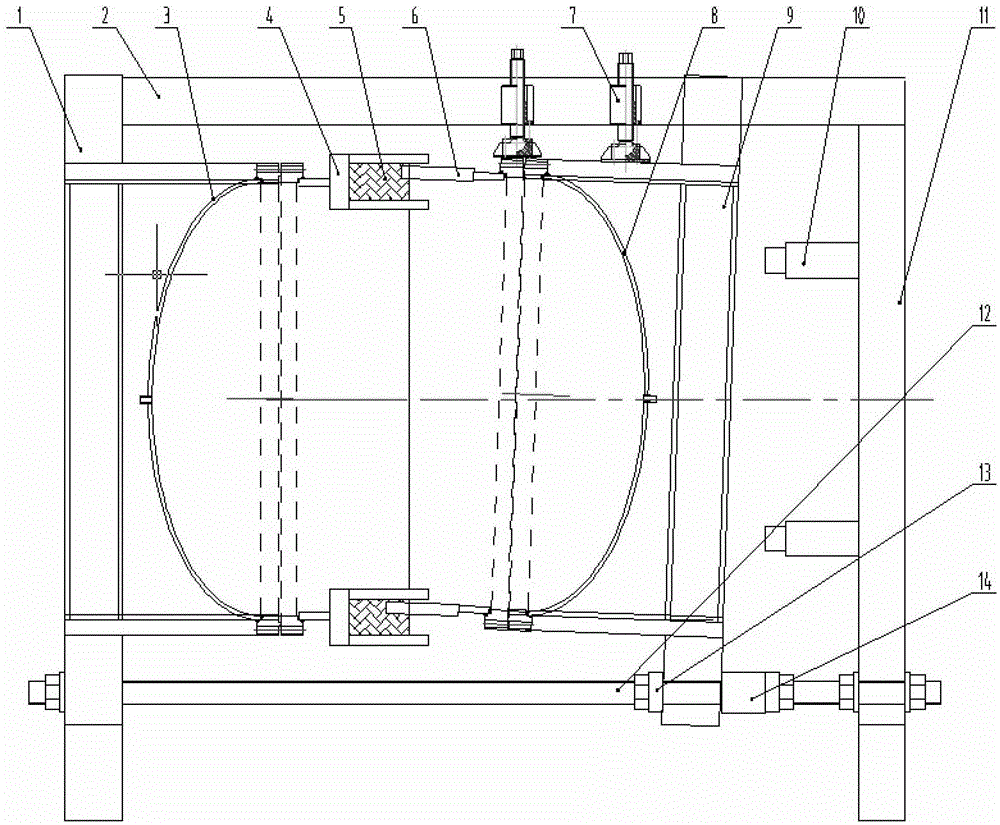

[0016] see figure 1 with figure 2 The structure diagram of the present invention shows that the shield butt joint sealing performance test device includes a front base 1, a plurality of frame beams 2, a plurality of pull rods 12, a rear base 11, a pressure chamber assembly, a top plate 9, a jacking oil cylinder group 10, an eccentric eccentric Angle adjustment screw group 7, attitude locking screw group 13 and load cell 14.

[0017] The front base 1 is a steel plate structure for connecting and fixing other components, and it is connected with the rear base 11 through a frame beam 2 and a tie rod 12, which are arranged around the pressure chamber assembly. In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com