UV prime paint roll coater

A roll coater and roll coater technology, applied in the direction of coating, liquid coating device on the surface, etc., to achieve the effects of high quality, labor saving and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

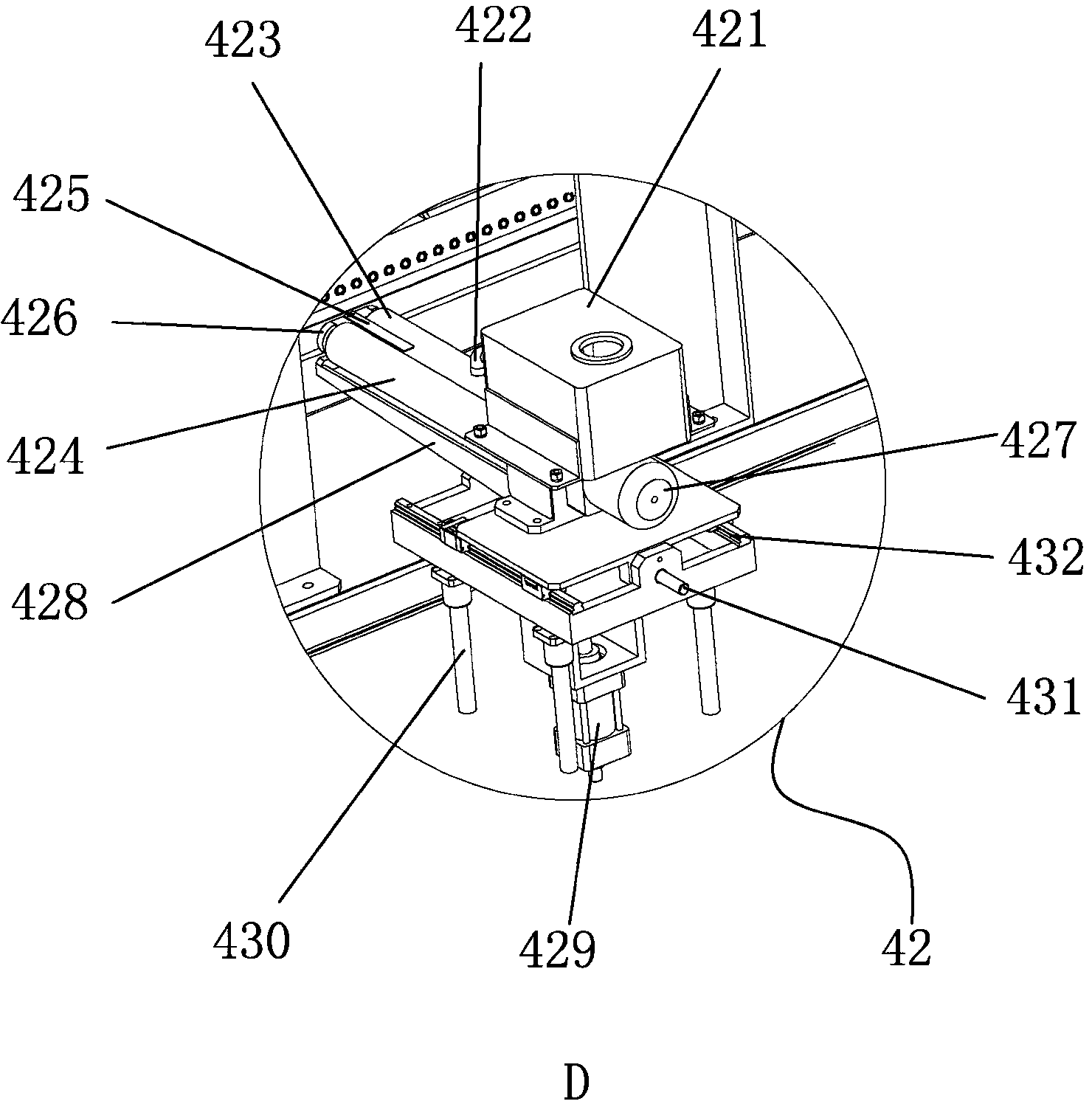

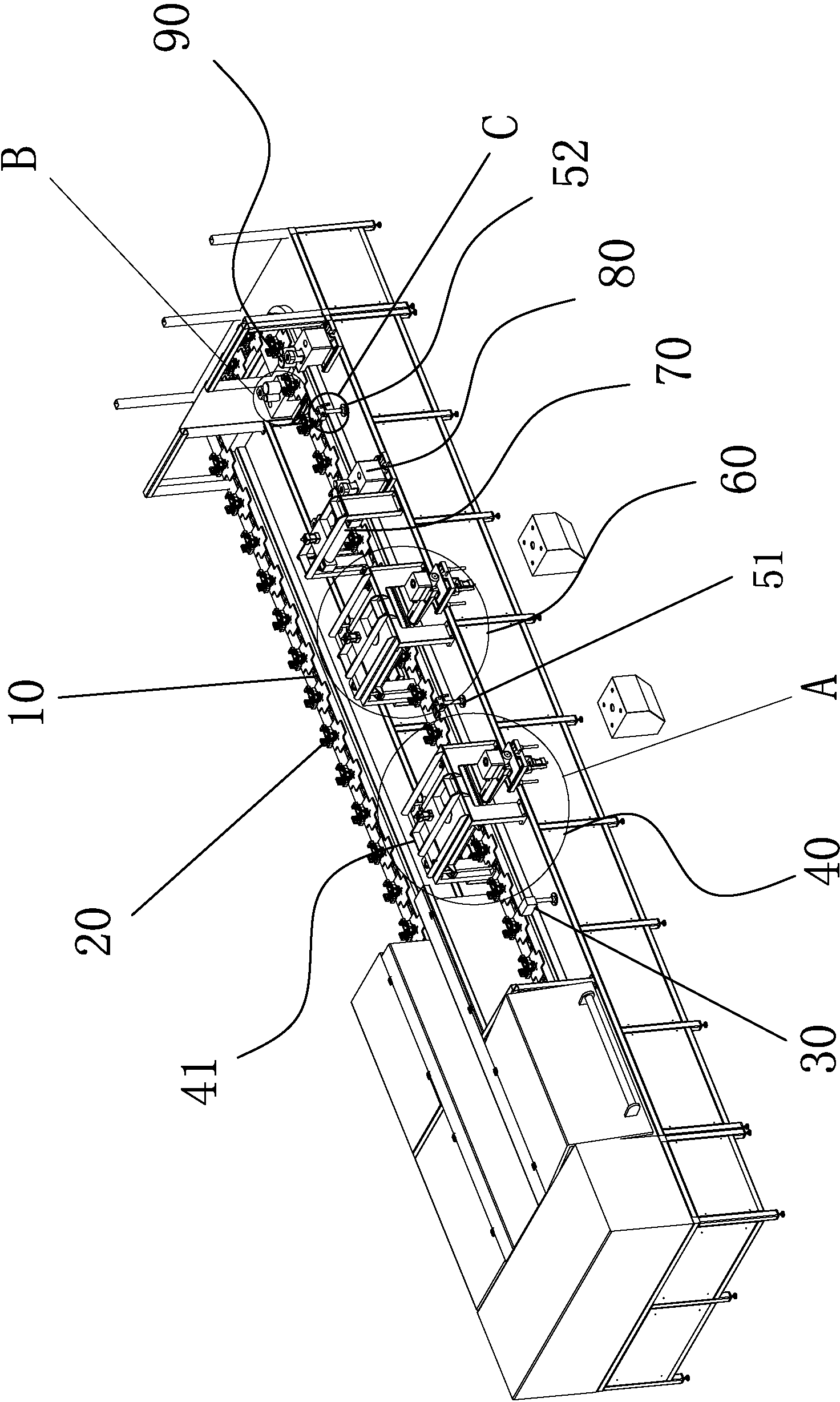

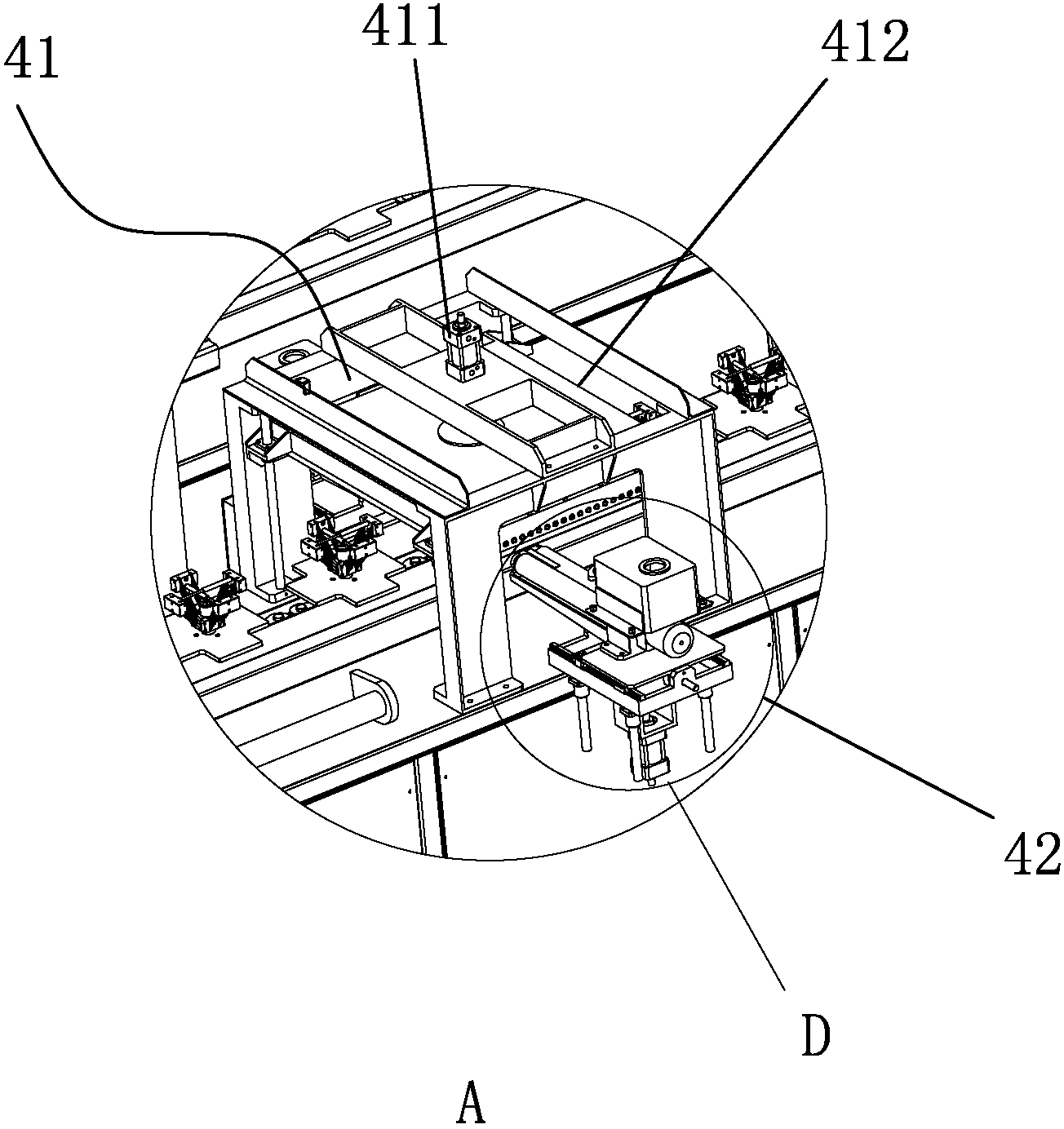

[0046] Such as figure 1 , figure 2 , image 3 , Figure 5 and Figure 6 As shown, a kind of UV primer roller coater of the present invention comprises packing box conveyer belt 10, and the clamp 20 that is used for fixing box cover or box body is arranged on packing box conveyer belt 10, arranges successively along packing box conveying direction There is: a judging device for judging whether the fixture is a lid or a box body, that is, an infrared detection device 30 . The first roller coating device 40 is used to coat the bottom of the opposite sides of the lid or the top of the opposite sides of the box body; the first roller coating device 40 includes a pressing device 41 and a symmetrical Two single-bottom roller coating devices 42 arranged on both sides of the packing box conveyor belt 10; the first 90-degree rotating device 51 is used to rotate the clamp by 90 degrees; The bottom of the side or the top of the other two sides of the box body is coated; the second r...

Embodiment 2

[0057] Two of the specific embodiment of a kind of UV primer roller coater of the present invention, as Figure 4 As shown, the main technical solutions of this embodiment are the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. and in Figure 4 neutralize figure 1 , figure 2 , image 3 The same parts bear the same reference numerals. The difference between this embodiment and embodiment 1 is:

[0058] The first side roller coating device 80 is two single side roller coating devices 81 symmetrically arranged on both sides of the packing box conveyor belt 10, and each single side roller coating device 81 includes a motor 427, a paint nozzle 812, a PU wheel 424, Metal anilox wheel 811, scraper fixed piece, scraper 425 and oil storage tank 421, motor 427, PU wheel 424, metal anilox wheel 811 and scraper fixed piece are arranged above oil storage tank 421, and the spout of paint noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com