Double-layer vibrating mesh sieve

A double-layer, mesh screen technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of large vibration weight, high energy consumption and large volume of vibrating screen, reduce volume and energy consumption, improve Screening efficiency, good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

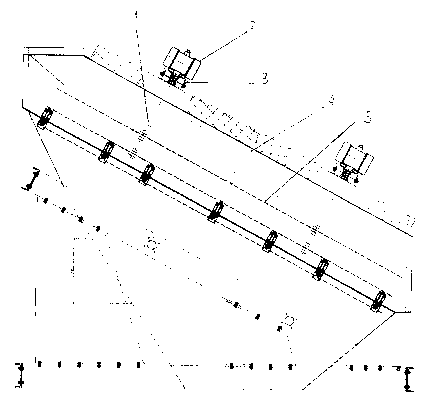

[0007] The embodiment is described in detail in conjunction with the accompanying drawings. The structure of the present invention is a double-layer vibrating screen, which includes a screen box 4, a vibrator 2 is installed on the top of the screen box, and the vibration output shaft 1 of the vibrator is connected to the screen box. The double-layer screen 5 inside is fixedly connected; the present embodiment can also be provided with shock absorber 3 at the bottom of described exciter, certain protection is carried out to exciter, can prolong the service life of exciter, this When the invention is in use, the vibrator directly drives the screen to vibrate. On the one hand, it can effectively prevent the screen from being blocked, and at the same time, it can also throw the materials to be screened and bounce forward for classification. The screening efficiency is high, and because The weight of the vibration part is small, which can effectively reduce the energy consumption of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com