Robot neck mechanism

A robot and neck technology, applied in manipulators, manufacturing tools, etc., can solve the problems of reduced service life, poor neck movement stability, long neck length, etc., to reduce manufacturing difficulty and volume, and have good stability and flexibility. , The effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

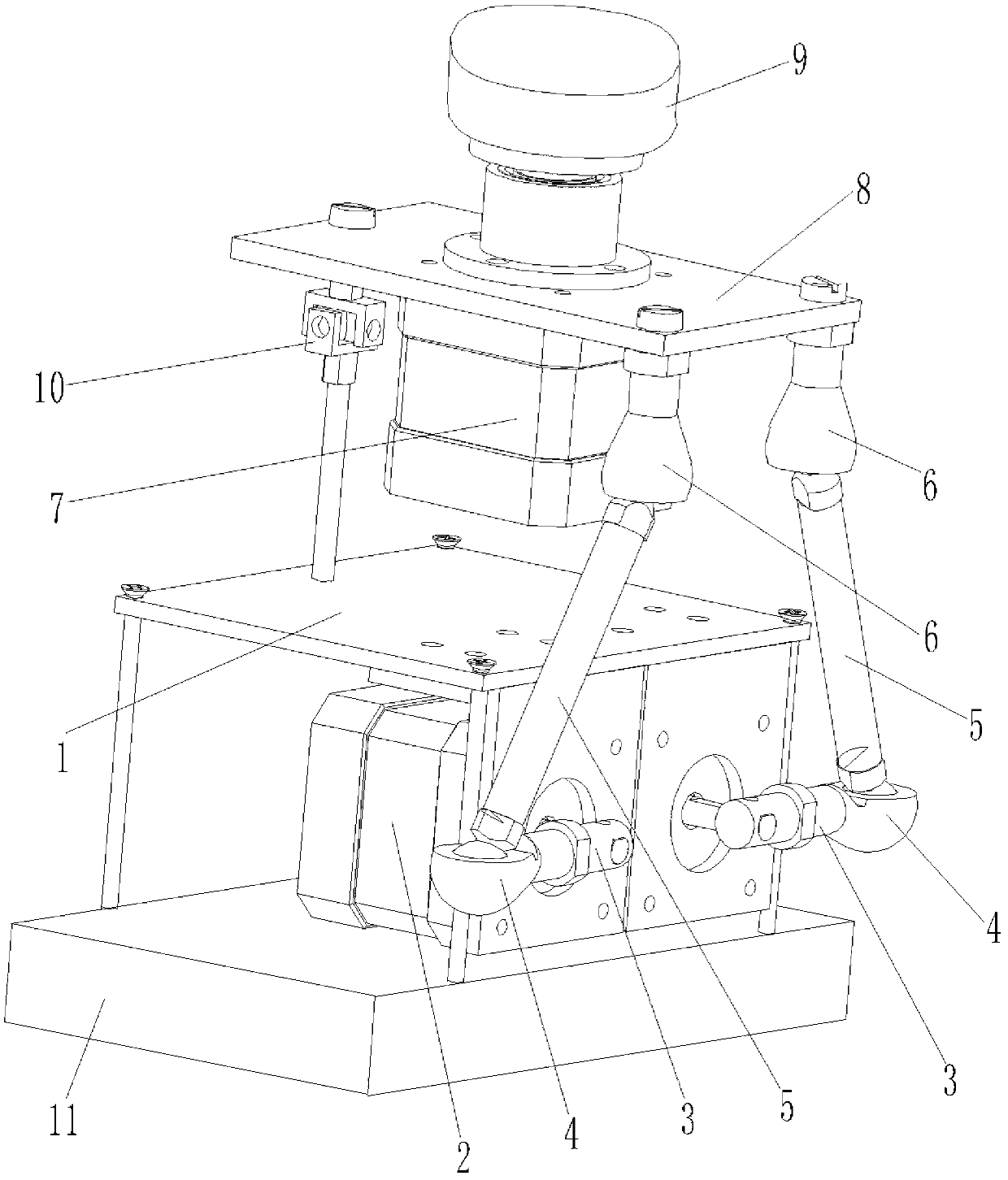

[0015] figure 1 As shown, a specific implementation of the present invention is a robot neck mechanism, including a neck lower frame 1 connected to the shoulder 11, and a neck upper frame 8 connected to the head 9, which is characterized in that :

[0016] The head rotating motor 7 is installed on the frame 8 on the neck, the shaft of the head rotating motor 7 is connected with the head 9, and the rear part of the frame 8 on the neck is connected with the lower part of the neck through a universal joint 10. The upper plate of the frame 1 is connected, and the front left and right sides of the frame 8 on the neck are respectively connected with the rotating shafts of the stepper motors 2 on the left and right sides of the frame 1 under the neck through a ball joint linkage mechanism; Among them, the specific composition of the ball joint linkage mechanism is:

[0017] The upper end of the upper ball joint 6 is fixed on the neck upper frame 8, the lower end of the upper ball j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com