Modularized pilotless helicopter for task loads

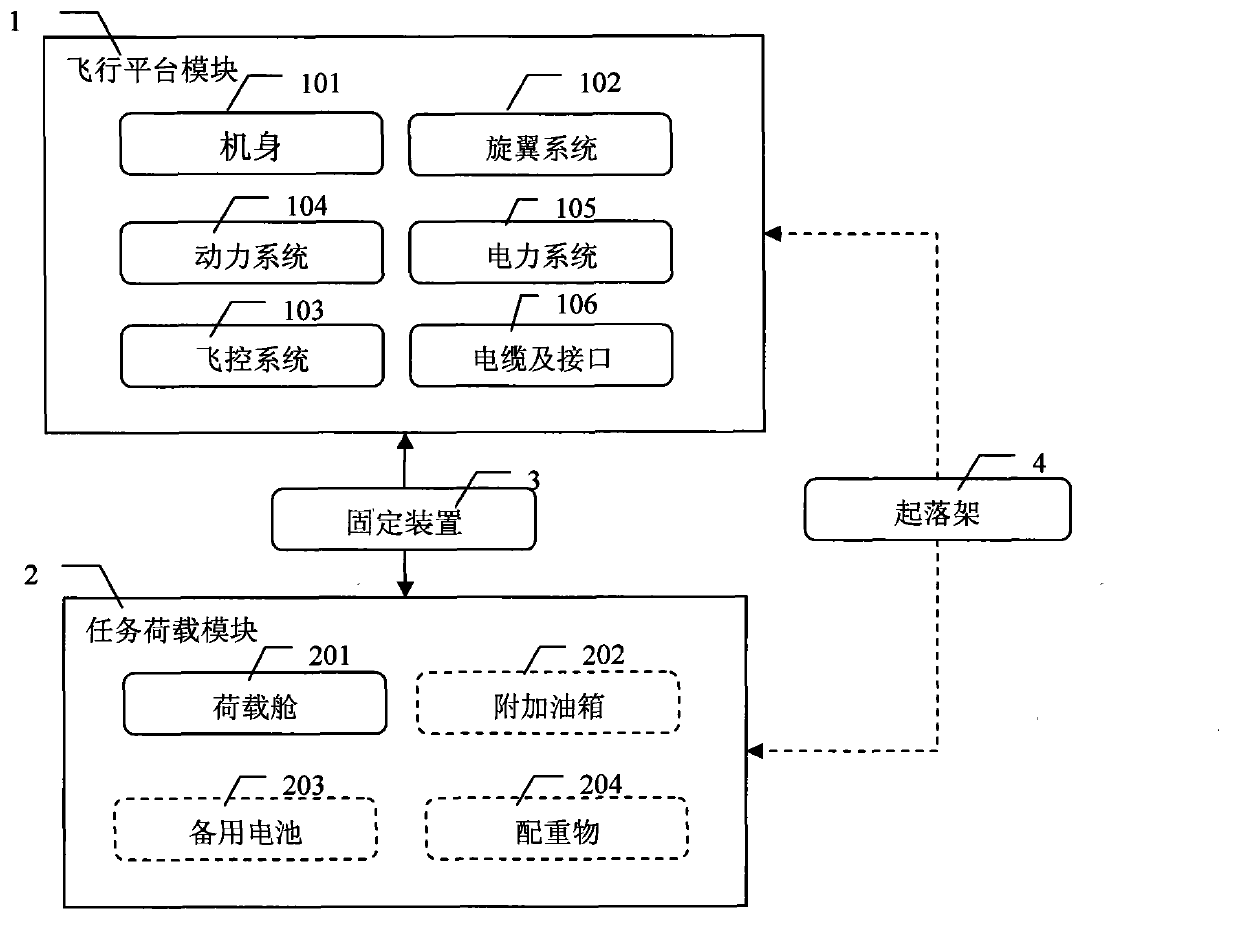

An unmanned helicopter and modular technology, applied in the field of unmanned aerial vehicles, can solve the problems of the limited shape and capacity of the unmanned helicopter load compartment, the complicated implementation of the external suspension method of the mission load, and the inability to apply the load equipment, so as to improve the multi-task execution. Capability, optimal flight efficiency, effect of increasing breadth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

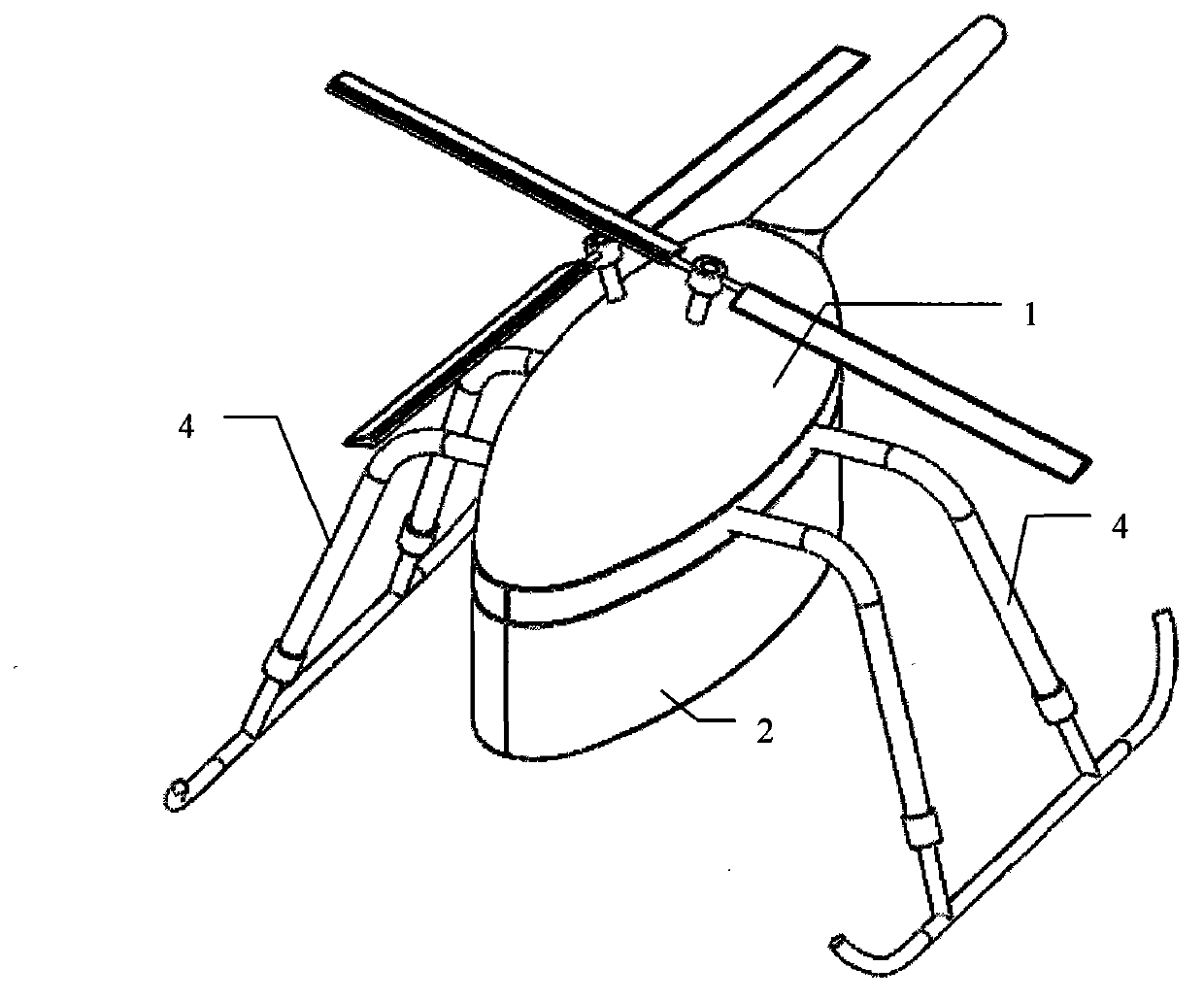

[0028] The overall structure of the unmanned helicopter is as follows: figure 2 As shown, the flight platform module 1 adopts a cross-type double-rotor rotor system 102, and the task load module 2 adopts an elliptical cabin structure. image 3 It is a schematic diagram of module decomposition. The landing gear 4 is installed on the frame of the flight platform module 1. The landing gear 4 is designed to be adjustable in height. The height of the landing gear 4 is adjusted according to the height of the task load module 2.

Embodiment 2

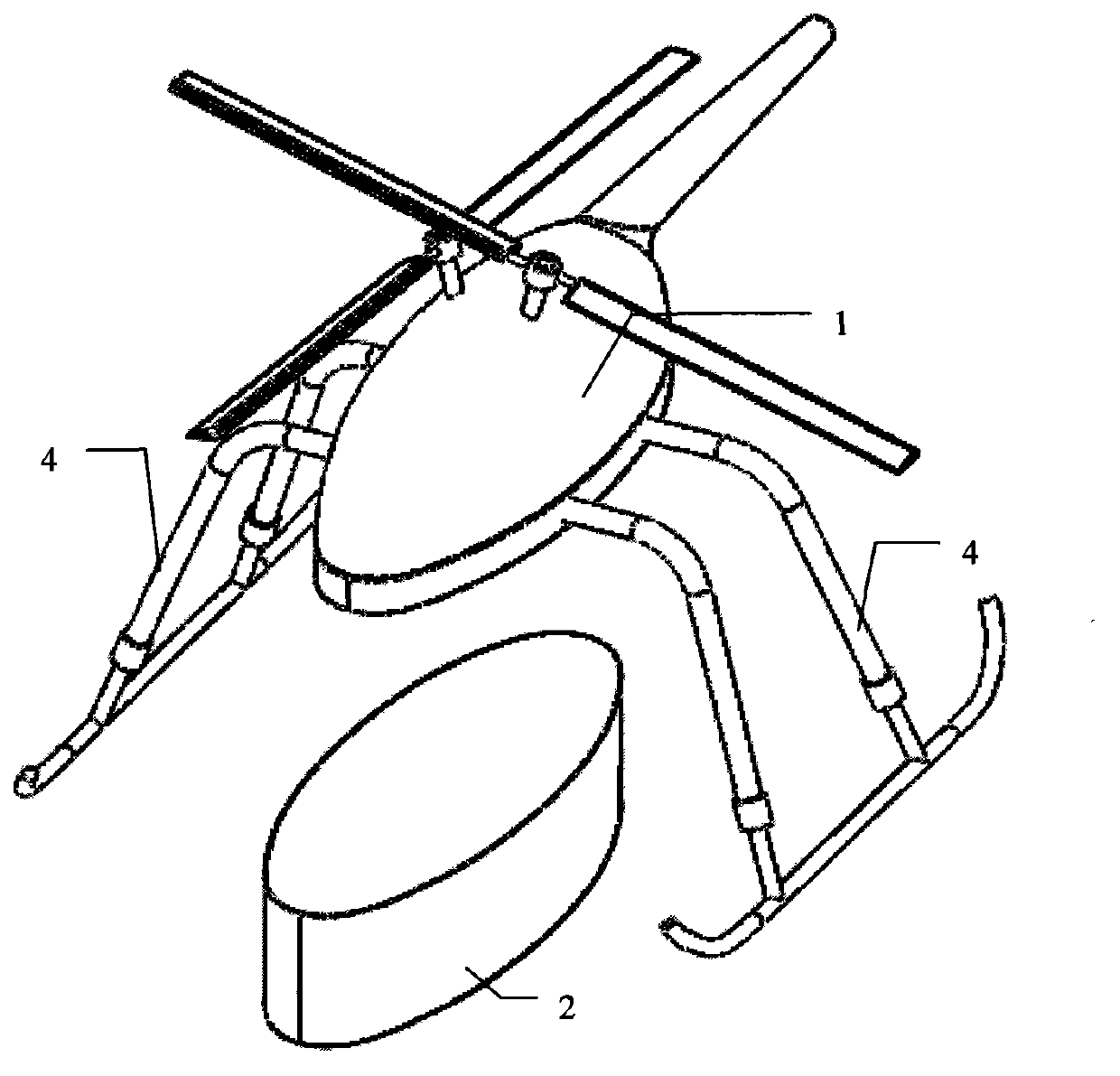

[0030] The overall structure of the unmanned helicopter is as follows: figure 2 As shown, the flight platform module 1 adopts a cross-type double-rotor rotor system 102, and the task load module 2 adopts an elliptical cabin structure. Figure 4 It is a schematic diagram of module decomposition. The landing gear 4 is installed on the frame of the task load module 2. The landing gear 4 is designed to be adjustable in height. The height of the landing gear 4 is adjusted according to the height of the task load module 2.

Embodiment 3

[0032] The overall structure of the unmanned helicopter is as follows: Figure 6 As shown, the flight platform module 1 is exactly the same as the flight platform module 1 in Embodiment 1, and the mission load module 2 is changed as Figure 5 The shape shown further increases the load capacity. The landing gear 4 is installed on the frame of the task load module 2 and is an adjustable height structure.

[0033] Figure 7 The flight platform module 1 in the example is a single-rotor tail rotor type, which can be used to replace the flight platform module 1 in Embodiments 1, 2 and 3 to form another unmanned helicopter.

[0034] A kind of flight platform module 1 can cooperate with multiple different task load modules 2, and likewise, a kind of task load module 2 can be used with multiple different flight platform modules 1, thereby improving the multi-function of the unmanned helicopter. task capability, broadening its scope of application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com