Belt subpackaging device

A kind of box dividing device and belt technology, applied in the directions of transportation and packaging, conveyors, etc., can solve the problems of large box retention, large installation gap, small box dumping, etc., to avoid retention or dumping, reduce installation gap, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

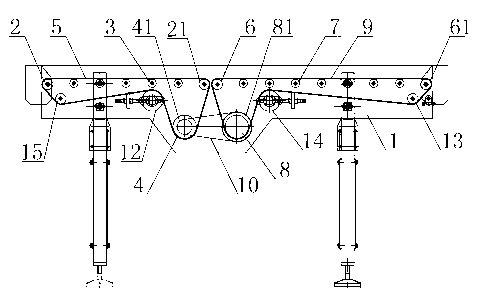

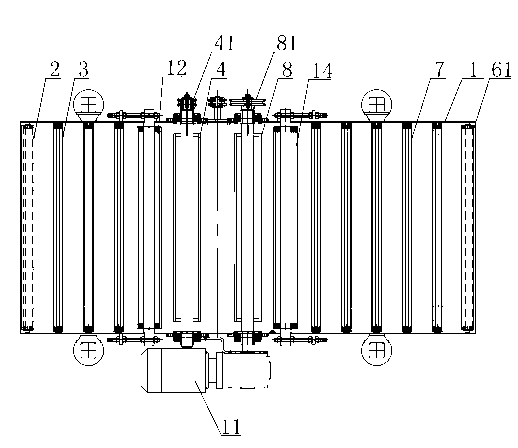

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and preferred embodiments.

[0011] A belt box sorting device, comprising: a frame 1, a front roller conveying mechanism and a rear roller conveying mechanism are arranged in sequence on the front and rear of the frame 1, and a front roller conveying mechanism and a rear roller conveying mechanism capable of driving the front roller conveying mechanism and the rear roller conveying mechanism are arranged on the frame 1 The mechanism conveys the case-dividing driving device at different speeds. The front roller conveying mechanism includes: the first front passive roller 2 and the second front passive roller 21 installed on the frame 1, and the two front passive rollers are arranged side by side There are some front unpowered rollers 3, and the front active roller 4 is installed on two front passive rollers 2 and 21 and on the frame 1 below the front unpowered rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com