Heat-treatment machining method of wear-resistant medium alloy steel castings

A processing method and alloy steel technology, applied in the field of heat treatment processing of wear-resistant alloy steel castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

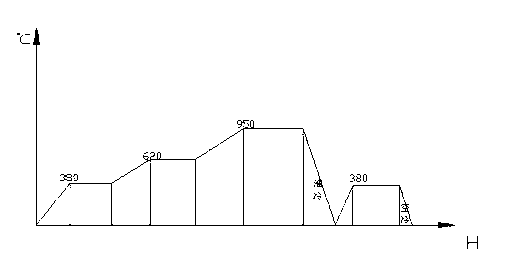

Image

Examples

Embodiment 1

[0011] Embodiment 1 is based on the present invention heat treatment process

[0012] The product name is wear-resistant steel lining plate, the specification model is medium alloy, and the sampling base is 150Kg;

[0013] Chemical Composition Inspection Items Technical Requirements Inspection Results

[0014] C,% 0.3-0.45 0.38

[0015] Si, % 1.0-1.7 1.7

[0016] Mn, % 0.6-1.3 1.2

[0017] P ,% ≤0.035 0.018

[0018] S ,% ≤0.03 0.01

[0019] Cr, % 1.5-2.2 1.8

[0020] Tensile strength Rm N / ㎜2 ≥ 500 1300

[0021] Elongation A after breaking, % ≥ 2 2.3

[0022] Hardness HRC ≥35 51.3; 52.0; 52.0

[0023] Impact toughness without opening J / cm2 ≥25 50; 68; 70

[0024] The products produced by the present invention are produced by the Jiangsu Product Quality Supervision and Inspection Research Institute according to GB / T4336-2002 [Carbon steel and low-alloy steel spark source atomic emission spectroscopic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com